How AI Improves Battery Management Systems in EVs

AI-Powered Predictive Maintenance for EV Batteries

Optimizing Battery Lifespan with AI

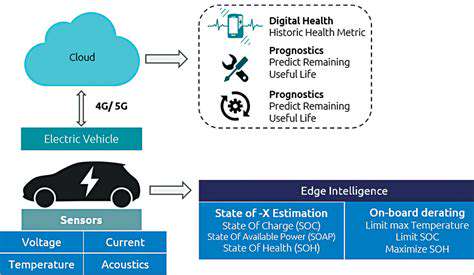

AI-powered predictive maintenance systems analyze vast amounts of data generated by electric vehicle (EV) batteries, enabling proactive identification of potential failures. This proactive approach allows for preventative maintenance, significantly extending the lifespan of EV batteries. By monitoring subtle changes in battery performance, such as voltage fluctuations or temperature variations, the algorithms can pinpoint impending issues before they escalate into costly repairs or even catastrophic failures, preventing unplanned downtime and maximizing the operational life of the battery system. This approach is critical to the long-term sustainability and cost-effectiveness of EV technology.

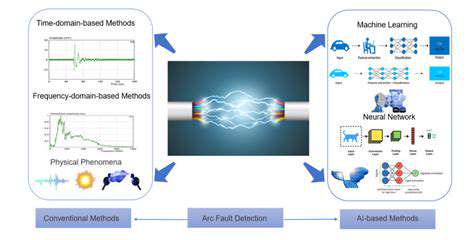

Data from various sensors, including those measuring temperature, voltage, and current, is meticulously collected and processed. Advanced machine learning algorithms then analyze this data, identifying patterns and anomalies that might indicate a potential problem. This anticipatory approach is superior to reactive maintenance strategies that only address issues after they occur, minimizing costly repairs and service disruptions. Through such preventative measures, AI truly unlocks the full potential of EV battery longevity.

Enhanced Safety through Proactive Monitoring

Predictive maintenance significantly enhances safety by anticipating potential battery failures. By detecting early warning signs of degradation, such as cell imbalance or thermal runaway, AI algorithms can trigger immediate intervention, preventing accidents or hazards. This proactive approach minimizes risks associated with sudden battery failures, ensuring passenger safety and preventing property damage. For example, detecting abnormal temperature patterns in specific battery cells can provide ample time to implement cooling measures or even initiate a controlled discharge protocol to mitigate the risk of a thermal runaway event.

Reducing Maintenance Costs and Downtime

Implementing AI-powered predictive maintenance dramatically reduces maintenance costs and downtime associated with EV batteries. By proactively addressing potential failures, owners avoid costly repairs and extended service periods. The system essentially minimizes the occurrence of unscheduled repairs, reducing the overall operational expenses for EV owners. This cost-effectiveness is crucial for widespread EV adoption and the economic viability of this technology. Furthermore, minimizing unplanned downtime keeps EVs on the road, maximizing their utilization and improving overall operational efficiency.

Preventative maintenance significantly reduces the need for costly and time-consuming repairs, translating to a lower total cost of ownership for EVs. Unforeseen issues that could lead to substantial repair bills are detected and addressed long before they impact operations, leading to substantial savings in the long run. Predictive maintenance is a powerful tool in optimizing the cost-effectiveness of EV ownership, promoting a more financially sustainable approach to battery management.

Improved Battery Performance and Efficiency

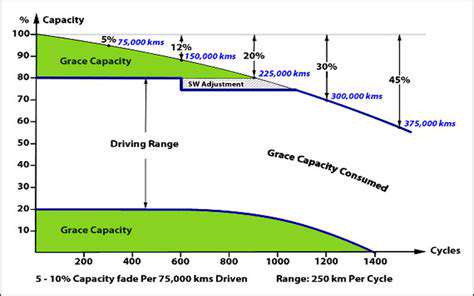

AI-driven predictive maintenance optimizes battery performance by fine-tuning charging and discharging cycles. By understanding the battery's health and condition in real-time, the system can adjust charging and discharging protocols to maximize efficiency and prolong battery life. This optimized approach allows for better utilization of the battery's capacity, reducing energy loss and boosting the range of EVs. AI's ability to adapt to varying conditions and battery degradation patterns ensures optimal performance throughout the battery's lifespan, maximizing energy efficiency and range.

Data-Driven Insights for Future Development

The data collected and analyzed by AI systems in predictive maintenance provides valuable insights for ongoing battery development and improvement. By identifying patterns of failure and degradation, manufacturers can improve battery designs, materials, and manufacturing processes, ultimately leading to a continuous advancement of EV technology. The insights gained from AI-driven analysis will drive innovation in EV battery technology, ensuring future advancements are built on a robust understanding of current performance limitations and potential improvement areas. This data-driven approach is vital for refining battery design and fostering long-term progress in the field of sustainable transportation.

Read more about How AI Improves Battery Management Systems in EVs

Hot Recommendations

- Offshore Wind for Industrial Power

- Agrivoltaics: Dual Land Use with Solar Energy Advancements: Sustainable Farming

- Hydrogen as an Energy Storage Medium: Production, Conversion, and Usage

- Utility Scale Battery Storage: Successful Project Case Studies

- The Role of Energy Storage in Grid Peak Shaving

- The Role of Startups in Renewable Energy

- The Role of Blockchain in Decentralization of Energy Generation

- The Future of Wind Energy Advancements in Design

- Synchronous Condensers and Grid Inertia in a Renewable Energy Grid

- Corporate Renewable Procurement for Government Agencies