How Aerodynamics Influence EV Range and Speed

Airflow and Vehicle Design

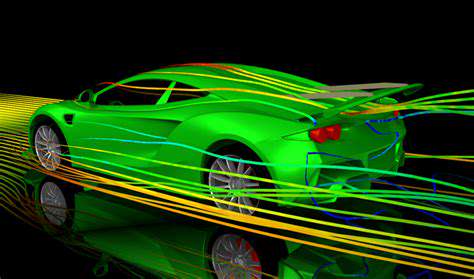

The interplay between airflow and vehicle shape is fundamental to achieving optimal performance and fuel efficiency. Engineers have long recognized that understanding how air interacts with a vehicle's exterior is crucial in reducing drag and maximizing aerodynamic efficiency. This involves analyzing complex airflow patterns, identifying pressure differentials, and strategically sculpting the vehicle's form to minimize resistance.

Drag Reduction Techniques

Modern automotive design prioritizes drag minimization through multiple approaches. Streamlining the vehicle's profile helps reduce turbulent airflow, while smooth, contoured surfaces decrease surface friction. Attention to underbody aerodynamics and wheel well design proves equally vital for optimizing airflow patterns.

Today's engineers employ computational fluid dynamics (CFD) to create precise airflow models, enabling targeted refinements to vehicle geometry. This scientific approach allows for incremental improvements that collectively enhance overall efficiency.

The Impact of Vehicle Shape on Fuel Efficiency

Aerodynamic optimization directly correlates with fuel economy. Vehicles experiencing reduced aerodynamic drag require less energy to maintain highway speeds, translating to measurable fuel savings. These efficiency gains contribute to both economic benefits for owners and environmental advantages through reduced emissions.

The Role of Computational Fluid Dynamics (CFD)

CFD has revolutionized aerodynamic development by enabling virtual wind tunnel testing. This technology allows designers to visualize airflow patterns with remarkable accuracy, identifying areas needing refinement before physical prototypes are built. The iterative nature of CFD analysis facilitates continuous improvement in vehicle aerodynamics.

Streamlining for Safety and Stability

Beyond efficiency, proper airflow management enhances high-speed stability. By minimizing turbulent airflow and optimizing pressure distribution, engineers create vehicles that maintain better road contact and handling characteristics. These improvements directly translate to enhanced safety margins during emergency maneuvers.

The Future of Aerodynamic Design

Emerging technologies promise further aerodynamic breakthroughs. Advanced composite materials and active aerodynamic systems adapt to driving conditions in real-time. The integration of machine learning with CFD analysis may enable self-optimizing vehicle shapes that continuously adjust for maximum efficiency throughout their operational life.

The Impact of Wheels and Tires on Drag

The Fundamental Role of Wheels in Mobility

Wheels represent one of humanity's most transformative inventions, fundamentally altering transportation and commerce. Their ability to convert sliding friction into rolling resistance enables efficient movement that would otherwise require exponentially greater energy expenditure. This mechanical advantage underlies modern transportation systems.

The circular form's elegance lies in its continuous motion potential. This geometry distributes loads evenly while minimizing surface wear, creating durable solutions for diverse applications from agriculture to aerospace.

The Evolution of Wheel Design

Wheel technology has progressed from solid wood discs to today's lightweight alloy constructions. The introduction of spoked wheels represented a watershed moment, dramatically reducing weight while maintaining structural integrity. Subsequent material advancements, particularly the adoption of steel and aluminum alloys, enabled higher load capacities and rotational speeds.

Modern manufacturing techniques allow for precision balancing and customized wheel geometries tailored to specific performance requirements, from heavy-duty trucking to high-performance racing.

Tire Technology and Its Significance

Tire development has paralleled wheel advancements, evolving from simple leather wraps to today's sophisticated radial constructions. Pneumatic tire technology fundamentally transformed ride quality and traction, while modern compound formulations optimize for varying road conditions and temperature ranges.

Contemporary tires incorporate multiple material layers, specialized tread patterns, and advanced wear indicators that collectively enhance safety and performance across diverse operating environments.

Impact on Transportation Systems

The wheel-tire combination underpins global mobility networks. This technology's scalability enables everything from personal bicycles to intercontinental shipping, creating economic linkages that span the planet. The standardization of wheel sizes and mounting systems has facilitated mass production and maintenance efficiency.

Modern logistics systems rely completely on wheeled transport, with just-in-time delivery networks and global supply chains depending on the reliability of wheel and tire performance.

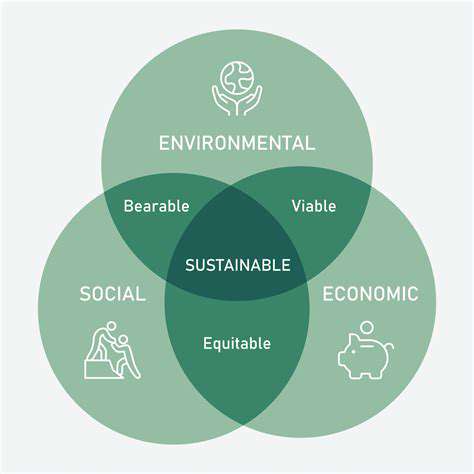

Environmental Considerations

While indispensable, wheel and tire systems present sustainability challenges. Tire particulate emissions and end-of-life disposal require innovative solutions as transportation volumes increase globally. Emerging technologies like airless tires and biodegradable compounds may help mitigate environmental impacts.

The industry continues developing recycling methods for tire materials while exploring alternative production processes that reduce energy consumption and hazardous byproducts.

Influence on Infrastructure

Transportation infrastructure has co-evolved with wheel technology. Road surfaces, bridge designs, and traffic systems all reflect the physical characteristics of wheeled vehicles. This symbiotic relationship continues shaping urban planning and rural development patterns worldwide.

Future infrastructure investments must account for evolving vehicle technologies while maintaining compatibility with existing wheel-based transportation systems that form the backbone of global commerce.

Read more about How Aerodynamics Influence EV Range and Speed

Hot Recommendations

- Offshore Wind for Industrial Power

- Agrivoltaics: Dual Land Use with Solar Energy Advancements: Sustainable Farming

- Hydrogen as an Energy Storage Medium: Production, Conversion, and Usage

- Utility Scale Battery Storage: Successful Project Case Studies

- The Role of Energy Storage in Grid Peak Shaving

- The Role of Startups in Renewable Energy

- The Role of Blockchain in Decentralization of Energy Generation

- The Future of Wind Energy Advancements in Design

- Synchronous Condensers and Grid Inertia in a Renewable Energy Grid

- Corporate Renewable Procurement for Government Agencies