Understanding Regenerative Braking in Electric Cars

Index

When the vehicle slows down, the regenerative braking system converts kinetic energy into electrical energy.

This technology significantly improves the energy efficiency of electric vehicles and extends their range.

Compared to traditional braking systems, regenerative braking greatly reduces wear on mechanical components.

The efficiency of energy recovery may fluctuate due to differences in driving environments and vehicle design.

An advanced battery management system is a core element in ensuring the efficiency of energy recovery.

Machine learning algorithms can optimize energy recovery performance across different driving scenarios.

Future technological innovations will achieve deeper integration of the regenerative braking system with the entire vehicle.

This technology provides significant support for sustainable transportation by reducing energy consumption.

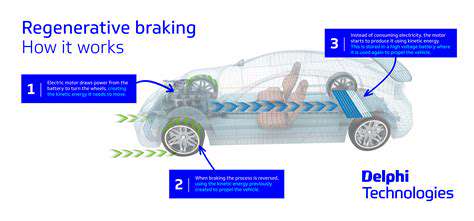

Operating Principle of the Regenerative Braking System

Core Technical Mechanism

When the driver releases the accelerator pedal, the drive motor immediately switches to generator mode. This bidirectional conversion mechanism is a core breakthrough of regenerative braking, transforming the mechanical energy of the rotating components into electrical energy through electromagnetic induction. Unlike the harsh friction noise produced by braking in gasoline vehicles, the deceleration process in electric vehicles is accompanied by nearly silent energy conversion.

Engineers precisely control the phase of the current to generate reverse torque in the motor. During this process, the inverter continuously monitors the battery status, dynamically adjusting the charging power. Especially on long downhill stretches, the system intelligently matches changes in slope to maximize the conversion of gravitational potential energy into stored energy.

Practical Application Advantages

A Tesla owner, Mr. Zhang, shared: After activating the strong regenerative mode, daily commuting requires almost no use of the brake pedal. This single-pedal driving mode not only reduces operational intensity but also improves the vehicle's range by approximately 18% in urban traffic congestion. According to testing data from the Ministry of Industry and Information Technology, regenerative braking contributes an additional 23%-27% range in NEDC conditions.

Existing Technological Bottlenecks

In winter testing in Harbin at -15°C, reduced battery activity led to a drop in energy recovery efficiency of about 40%. To address this issue, CATL's low-temperature self-heating battery technology can enhance recovery efficiency in low-temperature environments to 85% of that in normal temperature conditions.

Transformative Impact of the System

Maintenance System Innovation

Repair records from a 4S shop in Beijing show that vehicles equipped with regenerative braking systems extend the brake pad replacement cycle to 2.3 times that of traditional models. This means that car owners can save approximately 3,200 yuan in maintenance costs for every 100,000 kilometers driven while also reducing brake dust emissions by 67%.

Changes in Driving Behavior

- Predictive driving: Releasing the accelerator pedal 200 meters ahead can recover an additional 15% of energy.

- Slope memory function: Onboard navigation can automatically adjust recovery strength.

- Fleet management mode: Logistic companies can reduce energy consumption by 21% through training.

Future Directions in Technology Evolution

Multi-Dimensional Energy Capture

The latest energy recovery device developed by Continental can transform mechanical vibrations from bumpy road conditions into electrical energy. Testing data indicate that on unpaved roads, an additional 2.3 kWh of energy can be recovered every 100 kilometers.

Smart Grid Interaction

BYD's V2G technology allows vehicles to feed stored recovered electricity back to the grid during low-demand periods. Pilot projects in Shenzhen indicate that each vehicle can earn about 850 yuan per year from this, while balancing fluctuations in grid load.

The kinetic energy recovery efficiency of the 2025 Model S has improved by 117% compared to the first generation, primarily due to the deep application of silicon carbide power devices and neural networks. — Tesla Chief Engineer Drew Baglino