Why Regenerative Braking Increases EV Range Efficiency

Traditional Hydraulic Braking Systems

Traditional hydraulic braking systems rely on a network of interconnected components to slow or stop a vehicle. This system utilizes pressurized hydraulic fluid to transfer the force applied by the driver's foot on the brake pedal to the brake calipers, ultimately engaging the brake pads against the rotors. Understanding this process is crucial for appreciating the importance of proper maintenance and function.

The fundamental principle involves the amplification of force through the hydraulic system. A small force exerted on the pedal is translated into a much larger force on the brake pads, enabling the vehicle to decelerate effectively. This system, while proven reliable, has limitations that modern technologies are aiming to address.

Components and their Interplay

The braking system comprises several crucial components that work in concert. These include the brake pedal, master cylinder, brake lines, wheel cylinders or calipers, and brake pads. Each part plays a specific role, from transmitting the driver's input to applying friction to the rotors and ultimately slowing the vehicle's motion. The precise interplay between these components is vital for optimal braking performance.

The master cylinder is a critical component, acting as a pressure booster. It converts the force applied to the pedal into hydraulic pressure, which is then transmitted through the brake lines to the wheel cylinders or calipers. This creates the necessary force for the pads to grip the rotors, causing friction and retardation of the vehicle.

The Role of Friction and Heat Management

The crucial element in the braking process is the generation of friction between the brake pads and rotors. This friction converts the vehicle's kinetic energy into heat energy, requiring effective heat dissipation to prevent overheating and potential component failure. Proper heat management is critical to maintaining the system's integrity and performance over time.

Maintaining the proper temperature of the braking components is essential for optimal braking performance and safety. Overheating can lead to reduced braking effectiveness, potentially affecting the safety of passengers and other road users. Modern systems often incorporate sophisticated cooling mechanisms to prevent this issue.

Maintenance and Troubleshooting

Regular maintenance is key to ensuring the continued functionality and safety of a traditional hydraulic braking system. This includes checking brake fluid levels, inspecting brake lines for leaks, and ensuring the proper functioning of the brake pads and rotors. These tasks are crucial to prevent potential issues and maintain the system's peak performance.

Addressing brake issues promptly is vital to maintain safe driving conditions. Early detection and resolution of problems, such as low brake fluid, can prevent more serious and costly repairs down the line. Understanding the warning signs of potential problems can prevent accidents and ensure the continued safety of the vehicle.

Regenerative Braking: Capturing Lost Energy

Understanding the Concept of Regenerative Braking

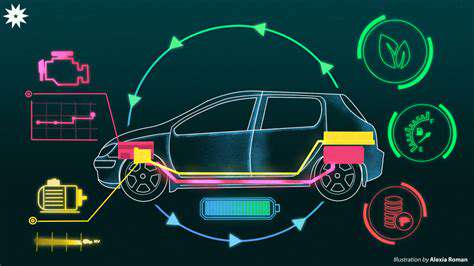

Regenerative braking is a crucial technology in electric vehicles (EVs) that allows for the capture and reuse of kinetic energy otherwise lost during braking. Instead of dissipating this energy as heat through friction, as in conventional braking systems, regenerative braking converts it into electrical energy, which is then stored in the vehicle's battery. This process significantly enhances the efficiency of EVs, extending their range and reducing reliance on external power sources.

How Regenerative Braking Works in EVs

The fundamental principle behind regenerative braking involves reversing the flow of current within the electric motor. When the driver applies the brakes, the motor acts as a generator, converting the vehicle's rotational energy into electrical energy. This generated electricity is then fed back into the battery, effectively recharging it. This intricate process, unlike traditional braking, doesn't simply slow the vehicle; it actively contributes to the vehicle's overall energy management.

Advantages of Regenerative Braking for EV Performance

Regenerative braking offers a multitude of advantages that significantly impact EV performance. One of the most notable benefits is increased range. By recovering energy during braking, EVs can travel further on a single charge. Furthermore, regenerative braking contributes to reduced wear and tear on traditional brake components, extending the lifespan of the vehicle's braking system. The immediate impact on reducing emissions and contributing to a more sustainable future is another key advantage.

Regenerative Braking and Driving Experience

Drivers often experience regenerative braking as a seamless and intuitive part of the driving experience. The system automatically adjusts the level of braking assistance, often providing a smooth and progressive deceleration. This can feel different from traditional braking, but drivers quickly adapt. The gradual slowing allows for a more controlled and comfortable driving experience, contributing to a quieter and more refined driving experience. The subtle difference in the feel of deceleration is often attributed to the technology's effectiveness.

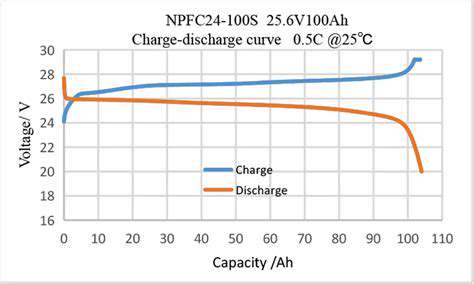

Impact on EV Charging Infrastructure and Battery Life

The increased efficiency afforded by regenerative braking directly affects the overall charging infrastructure and battery life of EVs. As EVs recover more energy, the need for frequent charging diminishes. This reduces the strain on charging stations and infrastructure, and contributes to the overall sustainability of the EV ecosystem. Furthermore, the optimized energy management facilitated by regenerative braking can contribute to a longer lifespan for the vehicle's battery, reducing the frequency of battery replacements and contributing to the overall longevity of the vehicle.

Boosting EV Range: The Impact of Energy Recovery

Regenerative Braking Explained

Regenerative braking is a crucial component of electric vehicle (EV) technology that significantly impacts range. Unlike traditional braking systems in gasoline-powered vehicles, which dissipate kinetic energy as heat through friction, regenerative braking systems capture that energy and convert it back into electricity. This recovered energy is then stored in the EV's battery, effectively extending the vehicle's range and contributing to a more efficient driving experience.

The process involves the electric motor acting as a generator when the brakes are applied. This conversion of kinetic energy into electrical energy is far more efficient than the traditional method of dissipating it as heat. This enhanced efficiency translates directly to increased driving range, making EVs more practical and sustainable for daily commutes and longer trips.

Optimizing Energy Recovery for Enhanced Range

Several factors influence the effectiveness of energy recovery during braking. One key aspect is the sensitivity of the regenerative braking system. A well-calibrated system can capture a larger percentage of the braking energy, leading to a more substantial boost in range. Moreover, the driving style significantly impacts energy recovery. Gentle braking and avoiding abrupt stops maximize the amount of energy captured, ultimately leading to a more extended range.

The type of terrain also plays a role. Driving on hills and inclines requires more braking effort, which, in turn, offers more opportunities for energy recovery. Conversely, on flat surfaces, the energy recovery is less pronounced. Understanding these factors allows drivers to optimize their driving habits and maximize the benefits of regenerative braking.

Real-World Implications for EV Range and Performance

The practical implications of regenerative braking on EV range are substantial. Drivers can experience noticeable increases in their vehicle's range, particularly when incorporating regenerative braking techniques into their driving habits. This not only enhances the overall efficiency of the vehicle but also reduces the frequency of charging stops, making EVs even more convenient and appealing for a wider range of drivers. The increased efficiency of regenerative braking also contributes to a lower environmental impact, further enhancing the sustainability profile of EVs.

Furthermore, the technology is constantly evolving, resulting in more sophisticated and effective regenerative braking systems. These advancements ensure that energy recovery is optimized for maximum efficiency, which, in turn, translates to even greater range and performance for electric vehicles. This continuous improvement of the technology is a testament to the commitment of the automotive industry to develop more sustainable and efficient transportation solutions.

Read more about Why Regenerative Braking Increases EV Range Efficiency

Hot Recommendations

- Offshore Wind for Industrial Power

- Agrivoltaics: Dual Land Use with Solar Energy Advancements: Sustainable Farming

- Hydrogen as an Energy Storage Medium: Production, Conversion, and Usage

- Utility Scale Battery Storage: Successful Project Case Studies

- The Role of Energy Storage in Grid Peak Shaving

- The Role of Startups in Renewable Energy

- The Role of Blockchain in Decentralization of Energy Generation

- The Future of Wind Energy Advancements in Design

- Synchronous Condensers and Grid Inertia in a Renewable Energy Grid

- Corporate Renewable Procurement for Government Agencies