Analyzing Volkswagen's Strategy for EV Market Dominance

Modular Electric Drive Matrix (MEB): A Game Changer

Volkswagen's MEB platform represents a significant leap forward in electric vehicle (EV) architecture. Its modular design allows for the creation of various vehicle types, from compact hatchbacks to SUVs, all sharing a common underpinning. This modularity fosters economies of scale and reduces development costs, a crucial factor in the competitive EV market. The MEB's adaptability is further evidenced by its ability to accommodate different battery chemistries and powertrain configurations, showcasing a flexible approach to future EV technology.

The MEB platform has been instrumental in Volkswagen's aggressive push into the electric vehicle market. Its flexibility allows for rapid adaptation to changing consumer demands and technological advancements, a vital component for staying ahead in the dynamic EV landscape. This adaptability is a key advantage in a market where innovation and adaptation are paramount.

Beyond the MEB: Exploring Alternative Architectures

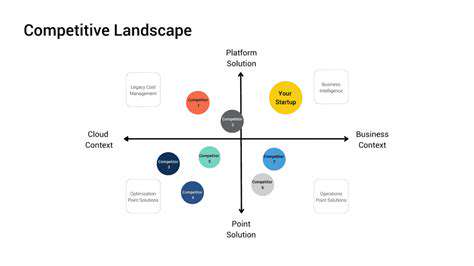

While the MEB has proven successful, Volkswagen is actively exploring alternative EV platforms. This demonstrates a proactive approach to future-proofing its EV strategy. Research and development into new modular architectures, potentially tailored for specific vehicle segments or performance characteristics, suggests a commitment to staying at the forefront of EV technology.

Volkswagen's exploration of alternative platforms suggests a willingness to adapt to evolving needs. The automotive industry is constantly shifting, and this adaptability is crucial for maintaining a competitive edge in the long run.

Battery Technology Integration: A Critical Component

The integration of battery technology is paramount to the success of any EV platform. Volkswagen's MEB and future platforms must be optimized for battery performance, range, and charging infrastructure compatibility. Efficient battery management systems are critical to maximizing the overall driving experience and user satisfaction. The constant advancement in battery technology requires a commitment to consistent updates and improvements.

Production Efficiency and Scalability

Building a robust EV platform requires not only innovative design but also efficient production processes. Volkswagen must optimize its manufacturing facilities to meet the demands of increased EV production. Scalability is crucial to meet projected market growth and maintain a competitive advantage. Efficient production processes are crucial for cost-effectiveness and timely delivery of vehicles to consumers.

Software Integration and Over-the-Air Updates

The software embedded within EVs is becoming increasingly critical. A robust EV platform must facilitate seamless software integration, enabling over-the-air updates for features, performance improvements, and security patches. This capability enhances the user experience and ensures long-term vehicle viability in the constantly evolving digital landscape. Integration of software is critical for long-term vehicle support and updates.

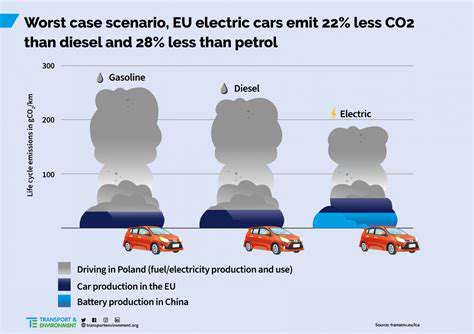

Supply Chain Resilience and Sustainability

Building an EV platform requires a robust and sustainable supply chain. Volkswagen must ensure access to critical materials like lithium and cobalt, while also incorporating sustainable practices throughout the production process. A resilient supply chain is crucial for meeting production targets and adhering to environmental standards. The sustainability of the supply chain is essential for long-term success and consumer trust.

Market Analysis and Consumer Feedback: Shaping the Future

Volkswagen needs to meticulously analyze market trends and gather consumer feedback to tailor its EV platforms to specific needs and preferences. Understanding consumer desires and evolving market demands is crucial for product development and refining features. Volkswagen must actively solicit and incorporate consumer feedback to ensure their vehicles meet the needs of the target market. This strategy is essential for maintaining customer satisfaction and ensuring the success of its EV platform.

Read more about Analyzing Volkswagen's Strategy for EV Market Dominance

Hot Recommendations

- Offshore Wind for Industrial Power

- Agrivoltaics: Dual Land Use with Solar Energy Advancements: Sustainable Farming

- Hydrogen as an Energy Storage Medium: Production, Conversion, and Usage

- Utility Scale Battery Storage: Successful Project Case Studies

- The Role of Energy Storage in Grid Peak Shaving

- The Role of Startups in Renewable Energy

- The Role of Blockchain in Decentralization of Energy Generation

- The Future of Wind Energy Advancements in Design

- Synchronous Condensers and Grid Inertia in a Renewable Energy Grid

- Corporate Renewable Procurement for Government Agencies