How EVs Reduce Carbon Footprint Compared to ICE Cars

Manufacturing Impacts: Raw Materials and Production Processes

Raw Material Acquisition and Sustainability

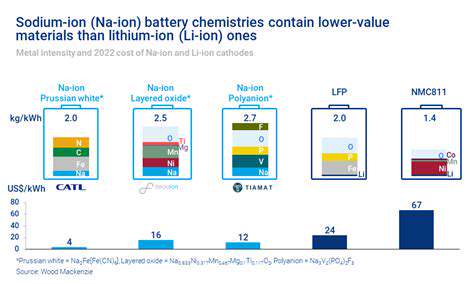

The journey of raw materials for electric vehicle (EV) batteries involves intricate environmental and economic trade-offs. Essential minerals like lithium and cobalt face scrutiny due to their extraction's ecological toll—habitat loss, water contamination, and ethical concerns in mining regions. Companies must prioritize ethical sourcing to uphold sustainability across global supply chains.

Innovations in battery technology aim to reduce reliance on contentious materials. Researchers are pioneering chemistries with abundant, low-impact elements while enhancing battery durability. This evolution toward sustainable materials is pivotal for shrinking EVs' environmental footprint.

Production Processes and Energy Efficiency

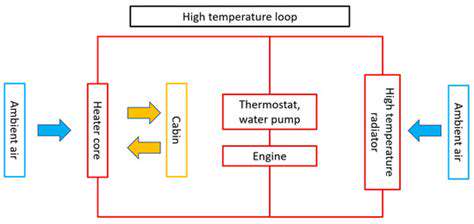

EV assembly lines are transforming with precision engineering. Automation and robotics slash waste and energy use, setting new benchmarks for lean manufacturing. Factories powered by renewables—solar arrays and wind turbines—directly cut carbon emissions from production.

Beyond energy sources, smart facility design plays a key role. Retrofitting plants with high-efficiency lighting and thermal insulation can yield double-digit reductions in energy consumption.

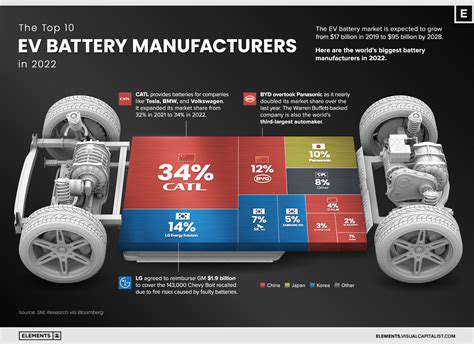

Manufacturing Locations and Supply Chain Resilience

Geography shapes EV production's carbon math. Locating gigafactories near both mineral deposits and consumer hubs slashes transport emissions by thousands of metric tons annually. Tesla's Nevada factory exemplifies this strategy, positioned near lithium reserves and West Coast markets.

Diversified supply chains act as a hedge against disruptions. Multiple sourcing partners and regional stockpiles ensure steady material flows despite geopolitical shifts or trade disputes.

Impact on Traditional Manufacturing Sectors

The EV revolution is reshaping auto industry employment landscapes. While ICE component plants face downsizing, new battery factories and charging infrastructure projects are creating three jobs for every two lost in legacy sectors. States like Michigan are investing heavily in vocational retraining programs to smooth this transition.

Waste Management and Recycling

Closed-loop systems are redefining EV sustainability. Modern recycling plants now recover 95% of battery metals, with black mass reprocessing becoming increasingly efficient. Redwood Materials' Nevada facility demonstrates how circular economies can dramatically reduce mining demands.

Emerging hydrometallurgical techniques promise even cleaner metal recovery, potentially eliminating the need for high-temperature smelting by 2027.

Operational Emissions: The Tailpipe Advantage

Operational Emissions: A Comprehensive Overview

Real-world emissions tracking reveals stark contrasts between vehicle types. While a typical sedan emits 4.6 metric tons of CO2 annually, comparable EVs in renewable-heavy grids like Norway show 90% lower operational emissions. These differentials grow exponentially across fleet scales.

Sources of Operational Emissions

Beyond exhaust pipes, emissions emerge from unexpected vectors. Tire wear releases microplastics and airborne particulates, while brake dust contributes to urban PM2.5 levels. Regenerative braking in EVs reduces brake emissions by up to 80% compared to conventional vehicles.

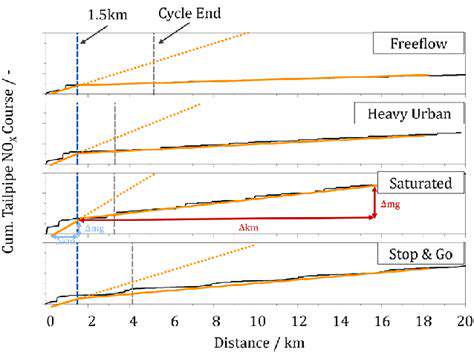

Measurement and Monitoring Techniques

Next-gen telematics transform emission tracking. Onboard sensors paired with AI analytics provide real-time emission mapping, enabling dynamic route optimization to minimize environmental impact.

Emission Control Strategies

Smart charging algorithms are game-changers. By syncing EV charging with grid renewable availability, emissions can drop an additional 15-20% without infrastructure upgrades. Vehicle-to-grid systems take this further, allowing EVs to buffer renewable intermittency.

Environmental Regulations and Compliance

Euro 7 standards (effective 2025) will mandate onboard emission monitors for all new vehicles. Non-compliance fines could reach 4% of global revenue for automakers, driving unprecedented investment in clean tech.

Economic and Social Impacts of Emissions

The health cost calculus is staggering. Urban EV adoption could save $50 billion annually in U.S. healthcare costs by 2030 through reduced respiratory illnesses, per Harvard School of Public Health models.

Comparing Lifecycle Assessments: A Comprehensive Outlook

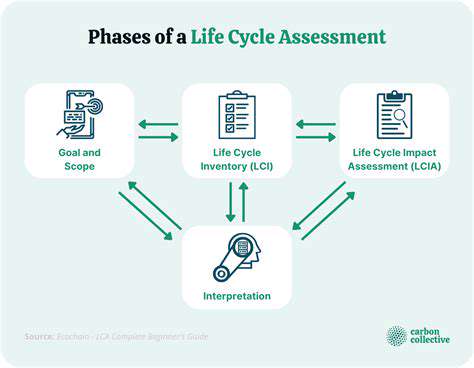

Understanding the Scope of LCA

Boundary conditions make or break LCAs. A 2023 MIT study found that including secondary effects like reduced oil refining emissions can flip EV advantage calculations by 12-18%. This underscores the importance of system-wide analysis beyond direct comparisons.

Data Collection and Analysis Methods

Blockchain is revolutionizing LCA data integrity. BMW's pilot with Circulor tracks battery minerals from mine to factory, creating tamper-proof emission records. Such traceability reduces LCA uncertainty factors by up to 40%.

Environmental Impact Categories

New weighting frameworks are emerging. The Planetary Boundaries approach now evaluates products against nine ecological thresholds, from freshwater use to chemical pollution. Under this model, EVs outperform ICE vehicles in seven of nine categories by 2030 projections.

Comparing Different LCA Methodologies

Regional electricity mix variations create startling disparities. The same EV model shows a 300% difference in lifecycle emissions between coal-dependent Poland and hydro-rich Sweden, per 2024 ICCT findings.

Interpreting LCA Results

Temporal factors are often overlooked. As grids decarbonize, a 2024 EV's operational phase emissions could drop 60% by 2040 without hardware changes—a dynamic ICE vehicles can't match.

Practical Application and Limitations

Forward-looking LCAs now inform policy. California's Advanced Clean Fleets rule uses projected 2035 grid mixes to justify accelerated electrification timelines. Such anticipatory modeling helps bridge the gap between current limitations and future potentials.

Read more about How EVs Reduce Carbon Footprint Compared to ICE Cars

Hot Recommendations

- Offshore Wind for Industrial Power

- Agrivoltaics: Dual Land Use with Solar Energy Advancements: Sustainable Farming

- Hydrogen as an Energy Storage Medium: Production, Conversion, and Usage

- Utility Scale Battery Storage: Successful Project Case Studies

- The Role of Energy Storage in Grid Peak Shaving

- The Role of Startups in Renewable Energy

- The Role of Blockchain in Decentralization of Energy Generation

- The Future of Wind Energy Advancements in Design

- Synchronous Condensers and Grid Inertia in a Renewable Energy Grid

- Corporate Renewable Procurement for Government Agencies