Offshore Wind Floating Foundation Designs (Semi submersible, Spar, TLP)

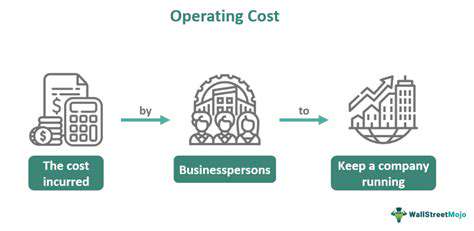

Offshore wind farms are becoming increasingly crucial for meeting global energy demands, but the challenging marine environments present unique engineering hurdles. A key aspect of these projects is the development of robust and cost-effective floatation systems that can support the massive wind turbines in deep waters. These systems must be designed to withstand the relentless forces of waves, currents, and storms, ensuring the longevity and reliability of the entire wind farm.

Different types of offshore wind floatation systems are being explored, each with its own set of advantages and disadvantages. Understanding these systems and their various applications is vital for the continued growth of renewable energy.

Key Components of Floating Wind Turbine Systems

Floating offshore wind turbine systems are complex structures requiring several key components for successful operation. These include the floating platform itself, the mooring system, and the transition piece connecting the platform to the turbine. Each component must be meticulously designed and constructed to withstand the harsh marine conditions and maintain the stability of the entire system.

The mooring system, in particular, is critical for securing the floating platform against the forces of wind and waves. Efficient and reliable mooring systems are essential for minimizing movement and maximizing the lifespan of the entire structure.

Challenges in Designing Floating Wind Turbines

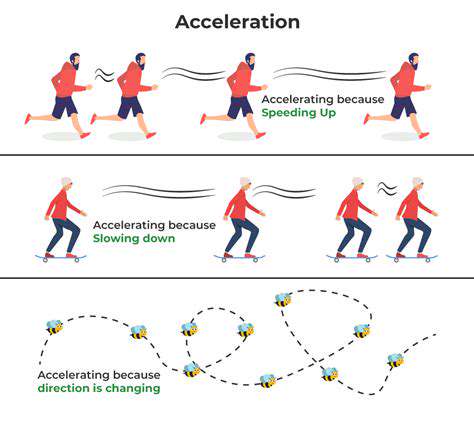

Developing floating offshore wind turbines presents a multitude of technical challenges. Significant engineering considerations include the interaction between the turbine, the platform, and the surrounding water. The dynamic behavior of the platform in response to external forces needs careful analysis and modeling to ensure structural integrity and prevent fatigue damage over time.

One major challenge is the prediction and mitigation of hydrodynamic loads, which can significantly impact the design and performance of the system. Advanced computational fluid dynamics (CFD) techniques are crucial for accurately modeling these forces and ensuring the stability of the floating platform.

Materials and Construction Techniques

Selecting appropriate materials and employing innovative construction techniques are vital for developing robust and cost-effective floating wind turbine systems. The materials must be capable of withstanding the corrosive nature of seawater and the mechanical stresses imposed by the marine environment. Advanced composite materials and innovative fabrication techniques are being explored to improve the structural efficiency and reduce the overall weight of the system.

Environmental Impact and Sustainability

The environmental impact of offshore wind farms, including floating systems, is a critical consideration in their development and deployment. Careful environmental assessments are essential to minimize potential negative impacts on marine ecosystems and wildlife. Minimizing noise pollution, avoiding habitat disruption, and ensuring safe operation are key aspects to integrating these renewable energy systems responsibly into coastal environments. Sustainable practices throughout the entire lifecycle of the project, from manufacturing to decommissioning, are paramount.

Semi-Submersible Floating Foundations: A Versatile Approach

Semi-Submersible Design Considerations

Semi-submersible platforms, characterized by their unique hull configuration, present a complex interplay of hydrodynamic and structural factors. Understanding these intricate relationships is crucial for ensuring the stability and operational safety of these complex structures. This involves meticulous analysis of wave forces, currents, and the platform's own dynamic response, all contributing to the overall design.

The design process often employs advanced computational fluid dynamics (CFD) models to simulate the platform's behavior under various environmental conditions. These simulations are invaluable for predicting the platform's motions and ensuring it can withstand the rigors of the offshore environment.

Structural Integrity and Material Selection

The structural integrity of a semi-submersible is paramount. The platform must be able to withstand the immense forces exerted by waves, currents, and the weight of the equipment and personnel aboard. This necessitates the selection of high-strength, corrosion-resistant materials.

Careful consideration must be given to the choice of materials to ensure long-term durability and prevent catastrophic failures. Factors such as fatigue, stress concentrations, and environmental exposure are all crucial elements to consider during the material selection process.

Dynamic Positioning and Control Systems

Maintaining the platform's precise position in the often-turbulent offshore environment is a critical aspect of semi-submersible operation. Advanced dynamic positioning (DP) systems are essential for maintaining a stable platform location, thereby preventing equipment damage and ensuring the safety of personnel.

Mooring Systems and Anchoring

Robust mooring systems are vital for maintaining the platform's stability in adverse weather conditions. These systems must be designed to withstand the enormous forces exerted by waves and currents. The design must also consider the long-term effects of environmental factors on the mooring lines and anchors.

The selection of appropriate anchor types and mooring configurations is critical, requiring careful evaluation of seabed conditions and anticipated environmental stresses. This ensures the platform remains safely moored and minimizes potential damage.

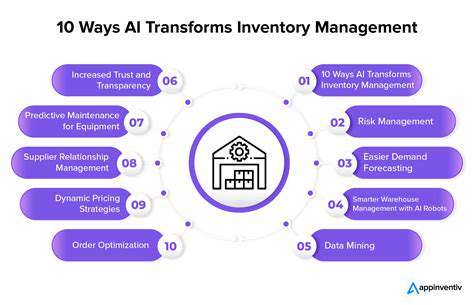

Operational Efficiency and Maintenance

Operational efficiency is a key consideration in the design of semi-submersible platforms. This includes the design of equipment arrangements, access points, and maintenance procedures to facilitate safe and efficient operation.

Minimizing downtime during maintenance and repairs is crucial to maximizing the platform's return on investment. Design features that facilitate efficient access and maintenance are essential for ensuring the long-term operational viability of the structure.