How Startups Are Disrupting the EV Ecosystem

AI-Driven Charging Optimization

Modern electric vehicles leverage cutting-edge algorithms to process live data streams encompassing energy costs, station availability, and driver behavior. This intelligent scheduling capability enables substantial savings by aligning charging sessions with off-peak rate periods. Consider how overnight charging during low-demand windows not only lowers expenses but also syncs with renewable energy generation cycles, creating environmental benefits.

These smart systems go beyond basic scheduling by anticipating potential disruptions. When detecting possible station congestion, the technology automatically redirects to alternative locations, eliminating frustrating wait times. This predictive functionality transforms the charging experience from reactive to proactive, ensuring drivers always find available power sources.

Predictive Maintenance for Enhanced Reliability

Sophisticated diagnostic tools continuously monitor the vehicle's vital systems - from battery health to motor efficiency. By analyzing subtle changes in performance metrics, the system can forecast maintenance needs weeks before they become critical. This forward-looking approach prevents roadside emergencies while extending component lifespan through timely interventions.

The psychological impact shouldn't be underestimated. Drivers enjoy greater peace of mind knowing their vehicle's condition is constantly evaluated by advanced monitoring systems. No more worrying about unexpected malfunctions during important trips or family vacations.

Personalized Driving Experiences

Every driver develops unique patterns behind the wheel. Smart systems recognize these individual preferences and automatically adjust dozens of parameters - from regenerative braking intensity to climate control settings. The vehicle essentially evolves with its owner, creating an increasingly tailored experience that improves with each journey.

Seamless Integration with Smart Home Systems

The modern smart home now extends to the driveway. Through intuitive interfaces, owners can precondition their vehicle's interior temperature, check charge status, or even plan routes - all from their living room. Imagine your car warming itself on winter mornings based on your home's automation schedule, or cooling down during summer heatwaves before you even open the door.

Revolutionizing EV Manufacturing: Efficiency and Affordability

Optimizing Production Lines

The heart of manufacturing innovation lies in production line optimization. Modern facilities employ robotic precision combined with intelligent material flow systems to eliminate inefficiencies. Automated guided vehicles transport components with millimeter accuracy, while machine vision systems ensure perfect assembly alignment every time.

Predictive analytics play a crucial role in maintaining continuous operation. By monitoring equipment vibration patterns, thermal signatures, and power consumption, potential failures are identified before they occur. This results in unprecedented uptime percentages that keep production humming around the clock.

Leveraging AI and Machine Learning

Artificial intelligence transforms raw production data into actionable insights. Deep learning algorithms detect microscopic defects invisible to human inspectors, while neural networks optimize material usage patterns to reduce waste. The most advanced systems can actually improve their own inspection criteria over time, constantly refining quality standards without human intervention.

Advanced Materials and Manufacturing Techniques

Material science breakthroughs enable lighter, stronger vehicle architectures. Novel aluminum alloys provide crash protection while shedding kilograms, and composite materials allow for aerodynamic shapes impossible with traditional metals. Additive manufacturing unlocks new design possibilities, creating complex cooling channels within battery housings or topology-optimized structural components.

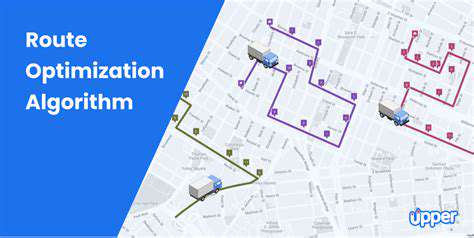

Supply Chain Management Innovations

Global supply networks require intelligent coordination. Blockchain-enabled tracking provides real-time visibility from mine to assembly line, while machine learning predicts regional demand fluctuations to optimize inventory levels. These digital supply chains automatically reroute shipments around disruptions, ensuring just-in-time delivery despite global uncertainties.

Sustainable Practices and Environmental Impact

The green revolution extends to factory operations. Solar-powered plants, closed-loop water systems, and waste heat recovery technologies minimize ecological footprints. Manufacturers now view sustainability as both environmental responsibility and competitive advantage, with consumers increasingly favoring brands that demonstrate genuine commitment to green practices.

Improving Battery Production Efficiency

Battery manufacturing represents the industry's greatest technical challenge. New dry electrode coating techniques eliminate energy-intensive drying processes, while AI-controlled formation cycling optimizes cell performance. These innovations collectively drive down the most significant cost component in EV production, making electric vehicles accessible to broader markets.

The Rise of Sustainable Materials: Eco-Friendly Choices

The Growing Demand for Eco-Friendly Alternatives

Consumer consciousness has fundamentally shifted toward environmental stewardship. People increasingly question product origins and afterlife, creating unprecedented demand for sustainable solutions. This isn't mere marketing - it's a complete reevaluation of consumption patterns that's reshaping global supply chains from the ground up.

Innovative Sustainable Material Technologies

The materials revolution spans multiple fronts. Agricultural waste transforms into durable bioplastics, while ocean plastics find new life as high-strength construction materials. Breakthrough recycling technologies can now separate previously inseparable material combinations, enabling true circular economies. Meanwhile, self-healing polymers and photocatalytic coatings create products that actually improve with use.

The Impact on Various Industries

Fashion brands now grow leather alternatives from mushroom roots, while automotive interiors incorporate pineapple leaf fibers. Construction firms build with carbon-negative concrete alternatives, and food packaging dissolves harmlessly after use. The most forward-thinking companies don't just adopt sustainable materials - they redesign entire product lifecycles around them, creating systems where waste becomes impossible by design.

In the packaging sector, edible wrappers and plant-based barrier films are replacing petroleum plastics. These innovations don't just reduce pollution - they create entirely new consumer experiences, like flavored packaging that enhances the product it contains. The sustainability revolution is proving that environmental responsibility can drive both innovation and profitability.

Read more about How Startups Are Disrupting the EV Ecosystem

Hot Recommendations

- Offshore Wind for Industrial Power

- Agrivoltaics: Dual Land Use with Solar Energy Advancements: Sustainable Farming

- Hydrogen as an Energy Storage Medium: Production, Conversion, and Usage

- Utility Scale Battery Storage: Successful Project Case Studies

- The Role of Energy Storage in Grid Peak Shaving

- The Role of Startups in Renewable Energy

- The Role of Blockchain in Decentralization of Energy Generation

- The Future of Wind Energy Advancements in Design

- Synchronous Condensers and Grid Inertia in a Renewable Energy Grid

- Corporate Renewable Procurement for Government Agencies