The Importance of Certified EV Technicians

The Rise of Robotics in Repair Shops

Modern repair facilities are witnessing a silent revolution as robotic systems become indispensable. These mechanical assistants now handle everything from millimeter-perfect alignments to micro-welding tasks that would challenge human hands. The result? Repair bays hum with activity around the clock, delivering consistent quality that keeps customers returning.

Imagine walking into a service center where articulated arms perform ballet-like movements, their laser-guided sensors detecting imperfections invisible to the naked eye. This isn't science fiction - it's the new reality transforming how we maintain our vehicles. Meanwhile, skilled technicians transition into supervisory roles, overseeing multiple repair stations simultaneously.

AI-Powered Diagnostics and Predictive Maintenance

Today's vehicles come equipped with more computing power than early space shuttles, and smart shops are leveraging this. Advanced diagnostic systems now parse through thousands of data points in real-time, spotting potential issues before they leave customers stranded. This shift from reactive to proactive maintenance represents the single greatest advancement in automotive care since the invention of the lift.

Consider this scenario: Your car's onboard systems detect a subtle change in battery performance during your morning commute. By lunchtime, your preferred repair shop texts a maintenance recommendation with available appointment slots. This seamless integration of technology and service defines the new standard in vehicle care.

The Importance of Data Analytics in Repair Processes

Forward-thinking shops now treat repair data like gold mines of insight. Patterns emerge from service histories that predict regional component failures, seasonal maintenance needs, and even driving habit correlations. This intelligence allows shops to stock parts strategically, reducing wait times while improving cash flow through smarter inventory management.

One midwestern chain analyzed three years of transmission repairs and discovered a 22% higher failure rate in vehicles primarily driven on rural roads. This revelation allowed them to educate customers about preventive measures while optimizing their parts ordering - a win-win scenario powered by data.

The Impact of 3D Printing on Parts Production

The parts supply chain is undergoing its most radical transformation since Henry Ford's assembly line. With additive manufacturing, a repair shop in Dallas can now print a discontinued door handle for a classic car while another in Denver fabricates a custom battery bracket for an electric conversion. This localized production slashes wait times from weeks to hours while reducing environmental costs of shipping.

Picture this: A collision center receives a vintage Porsche with unique European trim pieces. Instead of scouring salvage yards, their in-house printer replicates the damaged components overnight using scans from undamaged areas. The result? A perfect match that preserves the vehicle's authenticity while keeping the repair economically viable.

The Evolution of Technician Training and Skills

The wrench-wielding mechanic of yesterday is giving way to a new breed of automotive specialist - part engineer, part data analyst, part technology interpreter. Modern training programs now emphasize system thinking over component replacement, preparing technicians for vehicles that update their own software overnight. This paradigm shift requires continuous education as vehicle architectures evolve at smartphone-like speeds.

Consider the curriculum at leading technical schools today: Students spend as much time interpreting diagnostic flowcharts and analyzing telemetry data as they do turning wrenches. The most sought-after graduates possess the rare ability to explain complex electrical gremlins to customers in plain language while simultaneously programming autonomous calibration routines.

Customer Experience in the Digital Age of Repair

Transparency has become the currency of trust in modern repair operations. Customers now expect real-time updates via text, photo documentation of worn components, and accurate time estimates - all before they've finished their first coffee at the waiting lounge. This hyper-connected service model turns one-time visitors into loyal advocates who appreciate being treated as informed partners in vehicle maintenance.

Imagine receiving a video message from your technician showing exactly why your brake service can't wait another month, complete with micrometer readings and comparison to manufacturer specifications. This level of communication, impossible a decade ago, now sets the standard for customer expectations in an industry historically plagued by distrust.

The Impact on Consumer Confidence and Industry Growth

The Correlation Between Certification and Consumer Trust

In an era of information overload, professional certifications serve as beacons of credibility. Customers navigating complex repair decisions increasingly rely on these third-party validations when choosing service providers. The most successful shops prominently display their EV specialist certifications, I-CAR gold class ratings, and manufacturer endorsements - tangible proof of their commitment to excellence.

Certified Products and Enhanced Industry Reputation

The ripple effects of certification extend far beyond individual shops. When entire networks adopt standardized training and equipment protocols, the industry's collective reputation rises. This virtuous cycle attracts better talent, justifies premium pricing, and ultimately delivers superior outcomes for vehicle owners. Regions with high concentrations of certified shops report significantly higher customer satisfaction scores across all repair categories.

The Role of Certification in Fostering Innovation

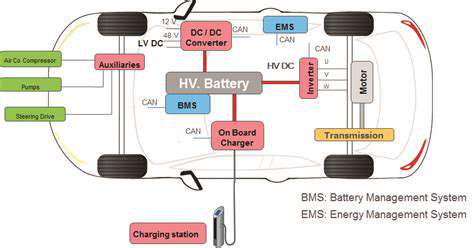

Certification bodies have become unexpected catalysts for technological advancement. Their evolving standards push manufacturers to develop safer, more efficient repair methods while giving shops clear roadmaps for equipment investments. The recent certification requirements for high-voltage system repairs, for instance, accelerated industry adoption of insulated tooling and advanced personal protective equipment by two years.

Certification as a Catalyst for Industry Growth

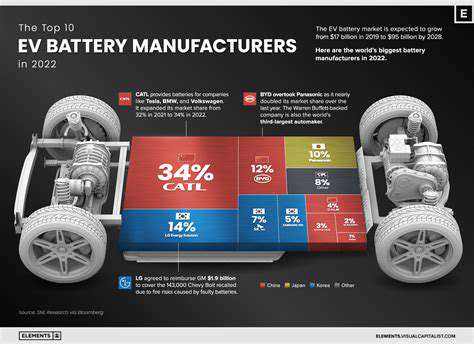

Market data reveals a striking pattern: Certified repair centers grow 37% faster than their uncertified counterparts while experiencing 42% lower employee turnover. This stability allows for greater investment in technology and training, creating a positive feedback loop that benefits the entire automotive ecosystem. Investors now view certification compliance as a key metric when evaluating aftermarket service chains.

Addressing Consumer Concerns Through Certification

The anxiety surrounding electric vehicle repairs provides a case study in certification's power. Shops that achieved recognized EV certifications saw a 68% higher conversion rate on service estimates compared to uncertified competitors. Customers willingly traveled farther and paid modest premiums for the assurance of working with properly credentialed technicians on their advanced vehicles.

Attracting Investment and International Trade

Globalization of the repair industry makes certification more valuable than ever. Multinational fleets and rental companies now mandate certified shops for their maintenance networks, creating lucrative contracts for compliant operations. This trend has sparked a wave of consolidation as regional players merge to achieve the scale necessary for comprehensive certification across all service lines.

The Impact on Market Competition and Sustainability

Certification requirements are quietly reshaping competitive dynamics. Rather than competing solely on price, top shops now differentiate through their certification portfolios and the measurable quality improvements they enable. This shift towards value-based competition benefits environmentally conscious consumers, as certified operations typically achieve 28% better waste diversion rates and 19% lower energy consumption per repair.

Read more about The Importance of Certified EV Technicians

Hot Recommendations

- The Role of Energy Storage in Grid Peak Shaving

- The Role of Startups in Renewable Energy

- The Role of Blockchain in Decentralization of Energy Generation

- The Future of Wind Energy Advancements in Design

- Synchronous Condensers and Grid Inertia in a Renewable Energy Grid

- Corporate Renewable Procurement for Government Agencies

- The Global Push for Long Duration Energy Storage

- Renewable Energy and Job Creation: A Growing Sector

- Energy Storage in Commercial and Industrial Applications

- Direct Air Capture (DAC) Powered by Renewable Energy