Why Temperature Control is Key for Battery Safety

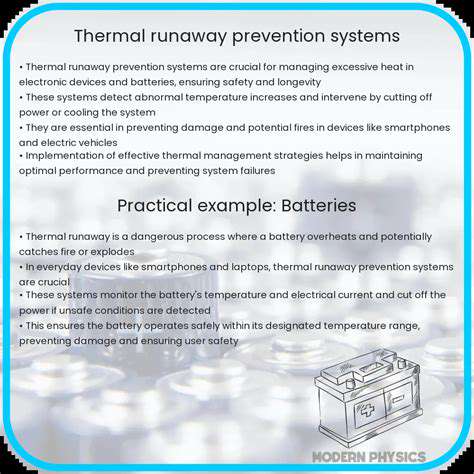

Understanding Thermal Runaway

Thermal runaway represents one of the most dangerous scenarios in modern engineering systems, especially those involving energy storage and conversion. When this chain reaction begins, it creates a feedback loop where rising temperatures accelerate chemical reactions, which in turn generate more heat. Left unchecked, this process can melt components, rupture containment systems, or even ignite fires within seconds.

Engineers across industries have observed that thermal runaway incidents often follow predictable patterns. The initial temperature spike might seem insignificant - perhaps just 5-10°C above normal operating range. However, this modest increase can trigger exothermic reactions that rapidly escalate beyond control thresholds.

Identifying Potential Triggers

Modern thermal analysis reveals multiple pathways to runaway conditions. Common culprits include:

- Cooling system failures (blocked vents, pump failures)

- Material defects (inconsistent thermal conductivity)

- Operational extremes (sustained high-load conditions)

- Environmental factors (high ambient temperatures)

What makes thermal runaway particularly insidious is how multiple minor issues can compound. A slightly undersized heat sink combined with marginally degraded thermal paste might perform adequately under normal conditions, but fail catastrophically during peak demand.

Design Strategies for Prevention

Cutting-edge thermal management approaches now incorporate several key principles:

- Distributed cooling architectures that eliminate single points of failure

- Phase-change materials that absorb excess heat through state transitions

- Smart materials that change conductivity based on temperature

The most effective designs implement multiple redundant cooling pathways, ensuring that if one system fails, others can compensate. Recent advances in microchannel cooling and graphene-based heat spreaders show particular promise for high-density applications.

Material Selection and Properties

Material engineers now emphasize three critical thermal properties:

| Property | Ideal Characteristics |

|---|---|

| Thermal Conductivity | High (>400 W/mK for critical paths) |

| Specific Heat Capacity | Moderate to high energy absorption |

| Thermal Expansion | Low coefficient matching adjacent materials |

Modern composite materials achieve previously impossible combinations of these properties. For example, carbon fiber reinforced metals provide structural integrity while maintaining excellent thermal pathways.

Cooling System Design and Optimization

Effective thermal management systems now employ:

- Variable-speed cooling matched to real-time thermal loads

- Predictive algorithms that anticipate heat generation patterns

- Self-diagnosing systems that detect degraded performance

The gold standard involves designing cooling capacity for 150% of worst-case scenarios, with multiple independent temperature monitoring points providing early warning of developing issues.

Monitoring and Control Systems

Modern monitoring solutions go beyond simple temperature thresholds:

- Distributed sensor networks create thermal maps

- Machine learning identifies abnormal patterns before critical levels

- Automated load shedding prevents cascade failures

Advanced systems now incorporate vibration analysis and gas detection to identify precursor conditions that often precede thermal events.

Safety Protocols and Redundancy

Best practices in thermal safety now mandate:

- Primary and secondary cooling systems with independent power

- Physical separation of critical components

- Automated emergency procedures with manual override

The most robust designs implement defense in depth with multiple independent safety layers, each capable of containing a developing thermal event.

Temperature Control Strategies for Enhanced Battery Safety

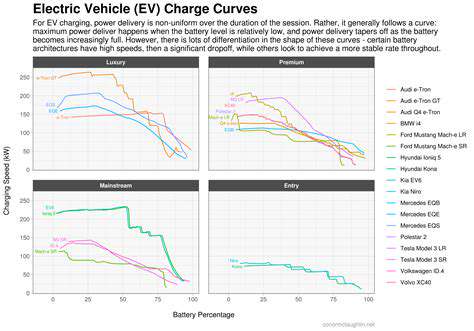

Optimizing Battery Performance Through Temperature Management

Battery experts universally agree that temperature management represents the single most important factor in battery longevity. The ideal operating window typically falls between 15°C and 35°C, with performance degrading approximately 2% per degree outside this range. Prolonged exposure to temperatures above 45°C can permanently reduce capacity by up to 30% per year.

Active Cooling Systems for Enhanced Safety

Contemporary active cooling solutions demonstrate several advantages:

- Liquid cooling achieves 3-5x better heat transfer than air

- Dielectric fluids enable direct component contact

- Modular designs simplify maintenance and upgrades

Modern electric vehicles now employ sophisticated coolant circulation systems that precisely regulate each battery module independently, maintaining optimal temperatures even during rapid charging.

Passive Heat Dissipation Techniques

Innovative passive approaches include:

- Heat pipes that transfer energy through phase change

- Thermal interface materials with engineered properties

- Radiative cooling surfaces that reject heat to space

Recent breakthroughs in metamaterials enable passive systems to rival active cooling in some applications, particularly where reliability and maintenance-free operation are critical.

Thermal Modeling and Simulation for Predictive Control

Advanced simulation tools now incorporate:

- Multi-physics coupling of electrical and thermal behavior

- Degradation modeling over thousands of cycles

- Real-world environmental condition libraries

These tools can predict thermal behavior with <5% error margins, enabling virtual prototyping that reduces development time and costs.

Material Selection for Thermal Management

The material selection matrix now considers:

| Requirement | Modern Solutions |

|---|---|

| Structural Support | Metal matrix composites |

| Electrical Isolation | Ceramic-filled polymers |

| Thermal Pathways | Oriented graphite sheets |

Next-generation materials combine traditionally incompatible properties, like electrically insulating yet thermally conductive ceramics.

Monitoring and Control Systems for Real-Time Adjustments

State-of-the-art monitoring systems feature:

- Embedded fiber optic temperature sensing

- Distributed impedance spectroscopy

- Cloud-based analytics for fleet-wide optimization

These systems can detect developing issues weeks before failure, enabling proactive maintenance and preventing catastrophic events.

Safety Mechanisms for Thermal Runaway Prevention

Comprehensive safety systems now incorporate:

- Pyrotechnic disconnects for millisecond-level isolation

- Intumescent materials that expand to smother fires

- Directional venting to channel gases safely

Modern designs can contain thermal events within single cells 99.9% of the time, a dramatic improvement over early battery technologies.

Read more about Why Temperature Control is Key for Battery Safety

Hot Recommendations

- Utility Scale Battery Storage: Successful Project Case Studies

- The Role of Energy Storage in Grid Peak Shaving

- The Role of Startups in Renewable Energy

- The Role of Blockchain in Decentralization of Energy Generation

- The Future of Wind Energy Advancements in Design

- Synchronous Condensers and Grid Inertia in a Renewable Energy Grid

- Corporate Renewable Procurement for Government Agencies

- The Global Push for Long Duration Energy Storage

- Renewable Energy and Job Creation: A Growing Sector

- Energy Storage in Commercial and Industrial Applications