Wind Energy in Cold Climates: De Icing Solutions

Preemptive Measures: Preventing Ice Accumulation

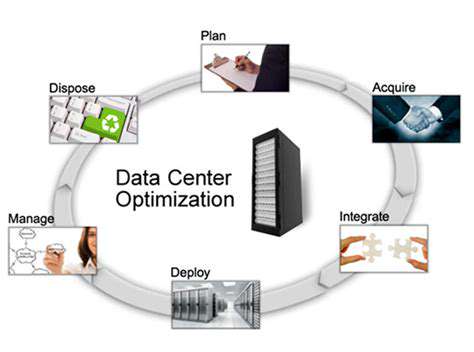

Proactive measures are crucial in mitigating the impact of icing on wind turbines. Implementing strategies to minimize ice formation in the first place significantly reduces the need for costly and potentially disruptive de-icing procedures. This involves careful site selection, considering factors like prevailing wind patterns, temperature fluctuations, and proximity to precipitation sources. Thorough analysis of historical weather data can help identify high-risk periods, allowing for preventative maintenance schedules and operational adjustments.

Regular monitoring of environmental conditions, including temperature, humidity, and precipitation, is essential. Early detection of icing tendencies allows operators to take timely action, such as adjusting turbine settings or implementing preemptive heating systems. Utilizing advanced weather forecasting models and incorporating real-time data feeds further enhances the accuracy of these predictions, enabling more effective preventative strategies.

Thermal De-Icing Systems: Utilizing Heat

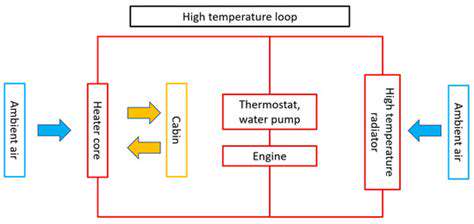

Employing thermal de-icing systems involves strategically placing heating elements on vulnerable turbine components, such as blades and nacelles. These systems use electrical resistance heaters or other heat sources to melt accumulated ice, preventing its buildup and maintaining optimal performance. Careful design and placement of these heating elements are crucial to ensure effective melting without overheating the surrounding structures or causing damage.

The efficiency of thermal de-icing systems depends heavily on the design and power consumption. Selecting the appropriate heating elements for specific turbine components, considering their size, shape, and exposure to the elements, is critical for optimal performance and cost-effectiveness. Proper insulation and heat distribution are also vital to prevent excessive energy consumption and maintain the desired temperature gradients.

Mechanical De-Icing: Employing Physical Removal

Mechanical de-icing methods involve the physical removal of ice from turbine components. This can include techniques like high-pressure water jets, which are effective for removing light ice accumulations but might not be suitable for thicker or more complex ice formations. More aggressive methods, such as specialized scraping tools or pneumatic systems, are sometimes necessary for removing substantial ice build-up.

Blade-Specific De-Icing Strategies

Wind turbine blades, due to their large surface area and aerodynamic sensitivity, are particularly susceptible to icing. Specialized de-icing techniques tailored to blades are often necessary. These methods may include the use of heated leading edges, strategically placed heating elements, or even specialized blade coatings designed to repel ice formation. Understanding the specific icing patterns experienced by the blade is critical for developing targeted de-icing solutions.

Operational Adjustments: Modifying Turbine Operation

Turbine operation can be adjusted to mitigate the impact of icing. This includes reducing rotational speed during periods of high icing risk, minimizing blade load, or even temporarily shutting down the turbine until the icing conditions subside. These operational adjustments may not fully eliminate ice build-up, but they can significantly reduce its impact on turbine performance and safety.

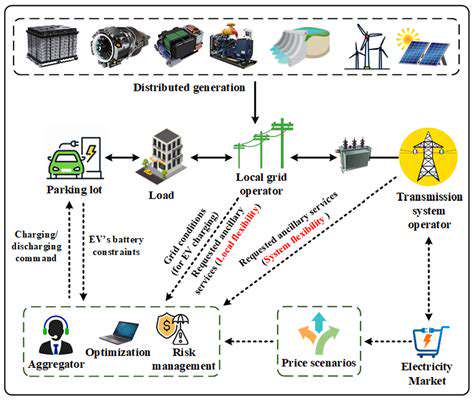

Implementing adaptive control systems is crucial. These systems allow for real-time adjustments to turbine operation based on environmental conditions, such as temperature, wind speed, and precipitation. This intelligent approach optimizes energy production and reduces the risk of damage or downtime caused by ice accumulation.

Environmental Factors: Understanding the Icing Process

The effectiveness of any de-icing method hinges on understanding the specific icing conditions at the wind turbine site. Factors such as air temperature, humidity, wind speed, and precipitation type all contribute to the rate and type of ice formation. Comprehensive meteorological data analysis is essential for developing effective de-icing strategies. This analysis helps predict the likelihood of icing events and the potential severity, allowing for proactive responses.

Economic Considerations: Balancing Cost and Efficiency

The optimal de-icing strategy must consider the economic implications. While some methods, such as thermal de-icing, might have higher upfront costs, they may prove more cost-effective in the long run due to reduced downtime and maintenance requirements. The long-term economic viability of each approach should be carefully assessed, considering the cost of implementing the system, the energy consumption of the system, and the potential for reduced generation. Comparing these factors is crucial to making informed decisions.

Read more about Wind Energy in Cold Climates: De Icing Solutions

Hot Recommendations

- Offshore Wind for Industrial Power

- Agrivoltaics: Dual Land Use with Solar Energy Advancements: Sustainable Farming

- Hydrogen as an Energy Storage Medium: Production, Conversion, and Usage

- Utility Scale Battery Storage: Successful Project Case Studies

- The Role of Energy Storage in Grid Peak Shaving

- The Role of Startups in Renewable Energy

- The Role of Blockchain in Decentralization of Energy Generation

- The Future of Wind Energy Advancements in Design

- Synchronous Condensers and Grid Inertia in a Renewable Energy Grid

- Corporate Renewable Procurement for Government Agencies