Comparing Environmental Impact of EV Manufacturing Processes

Energy Consumption in Metal Fabrication

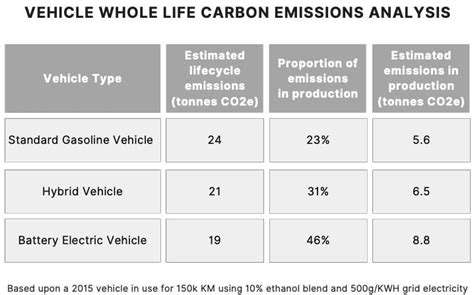

Metal fabrication, a cornerstone of numerous industries, often involves a substantial energy footprint. The processes, from initial material heating and shaping to finishing and assembly, require significant amounts of energy, predominantly in the form of electricity and gas. Understanding the energy consumption patterns in different metal fabrication techniques, such as casting, forging, and machining, is crucial for optimizing efficiency and reducing environmental impact. This analysis will delve into the various energy inputs for different metal fabrication methods, highlighting areas for potential improvement.

Different metal types and their processing requirements also contribute to the energy consumption variability. For example, the high melting points of certain alloys necessitate more energy-intensive heating processes. Furthermore, the scale of the operation—small workshops versus large-scale industrial plants—plays a crucial role in the overall energy consumption profile. This comparative study will examine the energy consumption per unit of output for diverse metal fabrication processes.

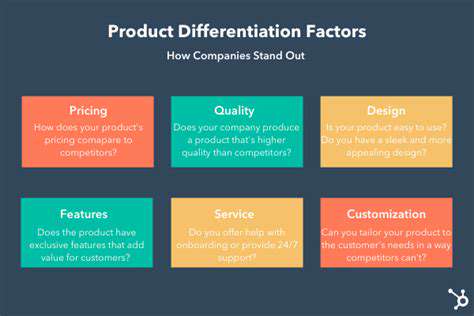

Impact of Material Selection on Energy Use

The choice of raw materials significantly influences the energy demands of manufacturing processes. Materials with high melting points or requiring specialized processing steps inherently demand more energy. For instance, the production of aluminum, which requires significant energy for smelting, has a higher energy footprint compared to steel production, which involves less energy-intensive processes. This section will explore the correlation between material properties and energy consumption in detail.

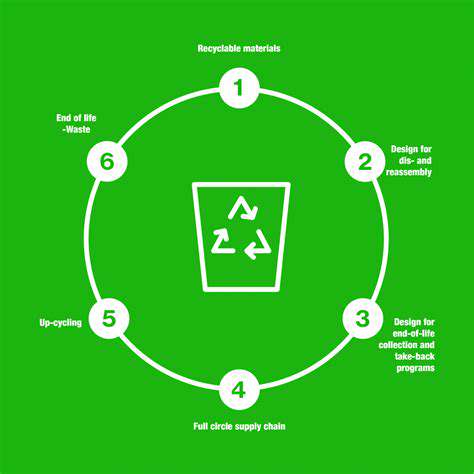

Recycling and the use of recycled materials also have a substantial impact on the energy consumption in manufacturing. Recycling often requires less energy compared to extracting and processing raw materials. Sustainable manufacturing practices, which emphasize the use of recycled materials, are critical for reducing the overall environmental impact of manufacturing processes. This analysis will investigate the energy savings achievable through the implementation of these practices.

Energy Efficiency in Casting Processes

Casting, a widely used manufacturing technique, involves pouring molten metal into molds to create desired shapes. The energy consumption in casting is primarily associated with melting the metal, which can be a highly energy-intensive process. Optimizing the melting process, using induction heating or other energy-efficient techniques, can significantly reduce the energy footprint. This section will focus on the various casting methods and their respective energy consumption patterns.

Furthermore, mold design and material selection play a key role in minimizing energy consumption during the casting process. Efficient mold designs can reduce heat loss and improve the overall efficiency of the casting process. This section will discuss the relationship between mold design, energy use, and overall manufacturing cost.

Energy Consumption in Machining Operations

Machining operations, including turning, milling, and drilling, consume significant energy, primarily through the use of machine tools. The energy consumption in machining depends on factors such as the material being machined, the tool type, the cutting speed, and the feed rate. Understanding these factors is crucial for optimizing energy consumption in machining processes. This section will look at the various machining operations and their respective energy consumption patterns.

Advanced machining techniques, such as computer numerical control (CNC) machining, offer opportunities to improve energy efficiency. CNC machines can be programmed to optimize cutting parameters, leading to reduced energy consumption and improved material removal rates. This section will evaluate the energy savings potential of CNC machining compared to traditional machining methods.

Sustainable Manufacturing Practices and Energy Reduction

Adopting sustainable manufacturing practices is essential for reducing energy consumption and minimizing environmental impact. These practices encompass a wide range of strategies, including material selection, process optimization, and energy recovery. This section will delve into the various sustainable manufacturing practices and their potential for energy reduction in different manufacturing sectors.

Implementing energy-efficient technologies and processes can lead to substantial reductions in energy consumption. Examples include using high-efficiency motors, implementing energy management systems, and optimizing lighting and ventilation in manufacturing facilities. This section will present case studies and examples of successful energy reduction initiatives in manufacturing settings.

Read more about Comparing Environmental Impact of EV Manufacturing Processes

Hot Recommendations

- Offshore Wind for Industrial Power

- Agrivoltaics: Dual Land Use with Solar Energy Advancements: Sustainable Farming

- Hydrogen as an Energy Storage Medium: Production, Conversion, and Usage

- Utility Scale Battery Storage: Successful Project Case Studies

- The Role of Energy Storage in Grid Peak Shaving

- The Role of Startups in Renewable Energy

- The Role of Blockchain in Decentralization of Energy Generation

- The Future of Wind Energy Advancements in Design

- Synchronous Condensers and Grid Inertia in a Renewable Energy Grid

- Corporate Renewable Procurement for Government Agencies