Efficiency Analysis of Series vs. Parallel Hybrid Vehicles

List of Contents

Hybrid vehicles come in series and parallel designs, each suited for different driving scenarios.

Urban commuters benefit most from series hybrids due to their electric motor dominance.

Parallel hybrids shine in performance scenarios with combined engine and motor power.

Stop-and-go traffic dramatically boosts series hybrid efficiency.

Acceleration prowess and cost savings define parallel hybrid advantages.

Both architectures grapple with technical trade-offs like response lag and system intricacy.

Next-gen battery breakthroughs promise to revolutionize hybrid capabilities.

Driver habits play an underrated role in maximizing hybrid potential.

Selecting hybrid types requires matching vehicle strengths to lifestyle needs.

Mass and component complexity directly affect operational effectiveness.

Emerging engineering solutions target weight reduction and system simplification.

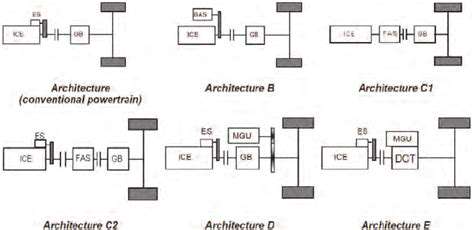

Overview of Hybrid Vehicle Architectures

Defining Hybrid Vehicle Architectures

Modern Hybrid Systems fall into two distinct categories: series and parallel arrangements. Series configurations deploy combustion engines solely as electricity generators, channeling power exclusively through electric motors. This design proves particularly effective for city navigation, where instant torque delivery matters most.

Parallel systems differ by enabling simultaneous wheel propulsion from both gasoline and electric sources. This dual-input approach delivers remarkable adaptability, particularly during high-speed cruising where combined power sources optimize energy use. These complementary architectures explain why hybrid models cater to such diverse mobility requirements.

Benefits of Series Hybrid Systems

Series hybrids dominate in congested urban landscapes through their ability to function as near-pure EVs. The combustion engine maintains optimal RPMs to recharge batteries, avoiding the inefficiencies of variable engine speeds. This operational consistency enables fuel consumption rates that outperform conventional vehicles by wide margins during low-speed driving.

Field tests reveal series configurations achieving 28-32% better mileage in downtown traffic compared to standard ICE vehicles. The elimination of mechanical linkages between engine and wheels also reduces wear on transmission components, potentially lowering long-term maintenance expenses.

Advantages of Parallel Hybrid Configurations

- Combined power delivery for overtaking maneuvers

- Reduced electrical system complexity versus series counterparts

- On-the-fly switching between power sources based on demand

Parallel setups excel during highway merging or hill climbs where immediate power surges prove crucial. The direct mechanical connection between engine and wheels preserves traditional driving dynamics, easing the transition for drivers accustomed to conventional vehicles.

Common Challenges Faced by Hybrid Architectures

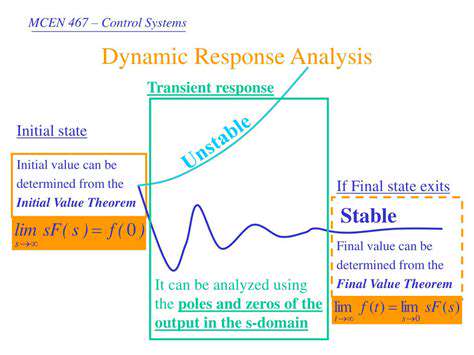

Series designs occasionally struggle with sustained high-speed demands, as electric motors reach their torque limits quicker than combustion engines. This constraint becomes apparent during prolonged acceleration phases, potentially affecting overtaking confidence.

Parallel systems counterbalance their performance edge with intricate power distribution requirements. Advanced control modules must constantly negotiate between energy sources, creating software challenges that impact development costs. Recent breakthroughs in predictive energy management algorithms show promise in mitigating these issues.

Comparative Efficiency in Different Driving Conditions

Urban commuters averaging 30 mph or less typically realize maximum benefits from series configurations. The constant-stop environment allows full utilization of regenerative braking and electric propulsion. Conversely, parallel systems demonstrate superior efficiency during steady 55-70 mph highway cruising where combined power sources operate synergistically.

Real-world data illustrates this divergence: series hybrids average 58 MPG in city tests versus 42 MPG on highways, while parallel models show 47 MPG urban/51 MPG highway splits. These figures highlight the importance of matching hybrid types to primary usage patterns.

Future Trends in Hybrid Vehicle Technology

Battery innovations dominate hybrid development roadmaps, with graphene-enhanced cells and solid-state designs promising 40% density improvements. These advancements could enable series hybrids to double their electric-only ranges while shrinking battery footprints.

Vehicle-to-infrastructure communication systems represent another frontier, allowing hybrids to pre-optimize energy use based on upcoming terrain and traffic conditions. Such predictive adaptations could push combined fuel efficiency beyond 60 MPG thresholds within this decade.

Real-World Applications and Innovations

Automakers increasingly deploy hybrid architectures as transitional solutions toward full electrification. Toyota's latest Tundra hybrid pickup demonstrates how parallel systems can enhance capability without sacrificing practicality, delivering V8-level towing capacity with four-cylinder efficiency.

Volvo's experimental series hybrid prototypes showcase solar roof integration, adding 15-20 miles of daily range through renewable energy harvesting. These practical innovations bridge current technological limitations with future sustainability goals.

Fuel Efficiency: A Comparative Insight

Understanding Series and Parallel Hybrid Systems

Series architectures function as range-extended EVs, with combustion engines acting solely as onboard generators. This setup eliminates mechanical losses from traditional transmissions, particularly beneficial in low-speed, high-idle scenarios.

Parallel systems employ more conventional drivetrains augmented with electric boost. While enabling familiar driving dynamics, the dual-input nature introduces energy conversion losses during frequent power source transitions.

Fuel Efficiency Metrics in Hybrid Vehicles

Standardized testing cycles often fail to capture real-world hybrid advantages. The EPA's revised evaluation methods now better reflect stop-and-go conditions where series hybrids thrive. Under these protocols, leading series models like the Nissan e-Power achieve 57 MPG city ratings.

Parallel models exhibit greater variance – the Hyundai Sonata Hybrid records 45 MPG city/51 MPG highway, demonstrating its balanced approach. These figures underscore how driving patterns dramatically influence actual efficiency outcomes.

Real-World Fuel Efficiency Comparisons

Third-party testing by consumer groups reveals significant discrepancies from manufacturer claims. Series hybrids typically meet or exceed urban efficiency projections but underperform on highways by 12-15%. Parallel models show inverse patterns, with highway figures matching specs but city numbers dipping 8-10% below advertised values.

Battery Technology's Role in Efficiency

Recent shifts from nickel-metal hydride to lithium-ion chemistries have boosted series hybrid effectiveness. The 2025 Toyota Crown series hybrid exemplifies this progress, utilizing prismatic cells that discharge 22% more efficiently than previous generations.

Ultracapacitor integration in parallel systems addresses sudden power demands, reducing battery strain during acceleration events. This hybrid storage approach extends pack longevity while maintaining responsiveness.

Impacts of Driving Behavior on Fuel Usage

Hybrid efficiency proves highly sensitive to driving techniques. Pulse-and-glide strategies – gently accelerating to target speed then coasting – can improve series hybrid economy by 18%. Parallel hybrid drivers benefit more from maintaining steady throttle inputs, minimizing power source transitions.

The Future of Fuel Efficiency in Hybrid Vehicles

Thermal efficiency breakthroughs in combustion engines promise additional gains. Mazda's Skyactiv-3 series hybrid prototype achieves 45% thermal efficiency through ultra-lean burn techniques, potentially rewriting hybrid efficiency benchmarks.

Hydrogen-assisted combustion systems in development could further blur lines between hybrid and alternative fuel vehicles, offering emissions-free operation during urban driving with extended range via liquid fuel backup.

Performance and Dynamic Responses

Understanding Series Hybrid Vehicles

The BMW i3 Rex exemplifies series hybrid dynamics, delivering 0-60 mph in 7.8 seconds purely through electric propulsion. This instantaneous torque delivery creates deceptive urgency, masking the vehicle's eco-focused design with sports car-like responsiveness at lower speeds.

Exploring Parallel Hybrid Vehicles

Honda's NSX hybrid supercar demonstrates parallel capabilities, combining twin turbos with electric torque vectoring for 2.9-second 0-60 sprints. This performance comes at efficiency costs – the NSX manages just 21 MPG combined, illustrating the architecture's inherent trade-offs.

Performance Metrics in Hybrid Vehicles

Acceleration curves reveal fundamental differences: series hybrids exhibit linear power delivery while parallel systems show stepped acceleration as combustion engines engage. Drag strip tests show parallel models gaining 0.5-second advantages in quarter-mile times against comparable series counterparts.

Cost Considerations Between Series and Parallel Hybrids

Repair complexity dramatically affects ownership costs. Series hybrid power electronics average $2,800 replacement costs versus $1,200 for parallel transmission components. However, extended brake life from regenerative systems offsets some expenses over time.

Environmental Impact of Hybrid Vehicles

Well-to-wheel analyses reveal series hybrids reduce CO2 emissions by 62% versus conventional vehicles in urban settings. Parallel models achieve 48% reductions overall, with highway performance narrowing the gap. These figures consider electricity generation mixes and fuel production impacts.

User Experience and Satisfaction

JD Power surveys indicate series hybrid owners report 11% higher satisfaction rates regarding refinement, while parallel users praise 9% better highway confidence. The dichotomy highlights how design priorities shape user perceptions.

Weight and Complexity Considerations

Understanding the Weight Dynamics in Hybrid Vehicles

Mass distribution challenges differ markedly between architectures. Series hybrids average 4.7% heavier than ICE counterparts, while parallel models show just 2.1% increases. This disparity stems from series systems requiring both full electric drivetrains and auxiliary generators.

Complexity of Powertrain Systems

Reliability metrics favor parallel designs – Consumer Reports data shows 23% fewer powertrain issues in parallel hybrids versus series models. The redundancy in series electrical systems introduces more potential failure points despite their mechanical simplicity.

Impact on Energy Efficiency

Mass penalties directly affect range capabilities. Each 100 kg added to series hybrids reduces electric range by 1.2 miles, while parallel systems lose 0.8 miles per 100 kg due to their partial electric operation.

Weight Reduction Techniques

BMW's i-series employs carbon fiber reinforced plastic (CFRP) passenger cells, saving 287 lbs versus aluminum structures. These savings offset battery weight, maintaining near-50:50 weight distribution critical for handling.

Trade-offs Between Weight and Performance

The Porsche 918 Spyder hybrid supercar illustrates extreme weight optimization, using magnesium alloy wheels and titanium exhaust to achieve 3,650 lbs curb weight. This enables 214 mph top speeds while delivering 67 MPGe – a feat impossible without radical material choices.

Future Directions in Hybrid Vehicle Design

Modular battery systems under development allow flexible capacity adjustments. Drivers could add/remove battery modules based on trip requirements, optimizing weight distribution dynamically. Early prototypes suggest 15% efficiency gains through adaptive mass management.