Emerging Technologies in Energy Storage: Beyond Lithium Ion

Solid-State Batteries: A Promising Future

A Revolutionary Approach to Energy Storage

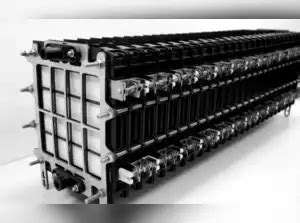

Solid-state batteries represent a significant advancement in energy storage technology, promising a paradigm shift from traditional lithium-ion batteries. These devices utilize solid electrolytes, replacing the flammable liquid electrolytes found in lithium-ion batteries. This fundamental change offers a multitude of potential benefits, including enhanced safety and significantly improved energy density.

The inherent safety characteristics of solid-state batteries stem from the elimination of flammable liquid electrolytes, significantly reducing the risk of thermal runaway and explosion. This feature is particularly crucial for applications like electric vehicles and portable electronics, where safety is paramount.

Enhanced Performance and Energy Density

One of the key advantages of solid-state batteries lies in their potential to deliver significantly higher energy density compared to their lithium-ion counterparts. This improved energy density translates to increased range for electric vehicles and longer operating times for portable devices. The ability to store more energy in a smaller space is a game-changer in various sectors.

Improved Cycling Life and Stability

Solid-state batteries demonstrate remarkable stability and longevity. Their solid electrolyte structure is far less prone to degradation over time compared to the liquid electrolytes commonly used in lithium-ion batteries, leading to a substantially improved cycling life. This enhanced durability is crucial for applications demanding repeated charging cycles.

Improved battery life translates to reduced maintenance costs and extended operational lifespan, making them more cost-effective and sustainable in the long run.

Materials and Manufacturing Challenges

Despite their significant promise, solid-state batteries are still facing challenges in material science and manufacturing. The development of suitable solid electrolytes is crucial for achieving the desired performance characteristics. Finding materials that offer high ionic conductivity while maintaining mechanical stability and chemical compatibility with electrodes is a complex task.

Furthermore, the manufacturing process of solid-state batteries is often more complex than that of lithium-ion batteries, requiring specialized equipment and techniques. Overcoming these manufacturing obstacles is essential for mass production and commercial viability.

Potential Applications and Future Outlook

The potential applications of solid-state batteries span various sectors, including electric vehicles, portable electronics, and grid-scale energy storage. Their enhanced safety, performance, and stability make them ideal candidates for applications demanding high energy density and long-term reliability.

The future of solid-state batteries looks promising, with ongoing research and development pushing the boundaries of this revolutionary technology. Continued progress in materials science and manufacturing techniques will pave the way for widespread adoption and integration into various aspects of modern life.

Metal-Air Batteries: A Potential Game Changer

Metal-Air Batteries: An Overview

Metal-air batteries represent a promising class of electrochemical energy storage devices, offering the potential for high energy density and reduced reliance on scarce resources compared to lithium-ion batteries. This high energy density stems from the use of atmospheric oxygen as the cathode, which inherently provides a vast reservoir of oxidant. This approach is particularly appealing for applications demanding high power and long cycle life, such as electric vehicles and portable electronics.

The fundamental principle of operation revolves around the electrochemical reaction between a metal anode and atmospheric oxygen. This reaction generates electricity, with the overall process being highly efficient.

Advantages of Metal-Air Batteries

One of the most significant advantages of metal-air batteries is their high theoretical energy density. This characteristic is a direct consequence of the use of oxygen as the cathode, a readily available and abundant component. This high energy density translates into potentially longer operating times for devices powered by these batteries.

Furthermore, metal-air batteries often exhibit a lower cost compared to other battery technologies, especially lithium-ion batteries. This cost-effectiveness stems from the lower cost of the materials used in the construction of the battery, particularly the abundant atmospheric oxygen.

Challenges in Metal-Air Battery Development

Despite their promising potential, metal-air batteries face several critical challenges that need to be addressed before widespread adoption. One significant hurdle is the sluggish kinetics of oxygen reduction/evolution reactions, which can limit the battery's performance and efficiency.

Another challenge lies in the development of robust and stable electrode materials that can withstand the harsh electrochemical environment. The corrosive nature of atmospheric oxygen and the high operating temperatures often encountered can degrade the electrode's structural integrity and catalytic activity over time.

Types of Metal-Air Batteries

Different metal-air batteries employ diverse metal anodes, each with its unique characteristics and performance properties. For instance, zinc-air batteries are known for their relatively low cost and abundant zinc source.

Other examples include aluminum-air batteries, which offer a superior energy density compared to zinc-air batteries, and lithium-air batteries, which show the highest theoretical energy density but present significant challenges in terms of material stability.

Electrode Materials and Their Importance

The choice of electrode materials plays a crucial role in determining the performance and longevity of metal-air batteries. High-performance catalysts are vital for facilitating the oxygen reduction/evolution reactions at the cathode. These catalysts are responsible for speeding up these reactions, which directly impacts the battery's overall efficiency and power output.

Similarly, the anode materials are critical for ensuring stability and preventing corrosion during the electrochemical reactions. Appropriate selection and development of these materials are critical for successful battery operation.

Performance Metrics and Characterization

Several performance metrics are used to evaluate the effectiveness of metal-air batteries, including energy density, power density, cycle life, and cost. These metrics provide a comprehensive understanding of the battery's operational characteristics and suitability for various applications.

Rigorous testing procedures and characterization techniques are essential to assess these performance metrics and identify areas for improvement. These methods help researchers fine-tune the battery design and optimize its performance parameters.

Applications and Future Prospects

The potential applications of metal-air batteries are broad and span across diverse sectors, including portable electronics, electric vehicles, and renewable energy storage systems. Their high energy density makes them particularly attractive for applications demanding long operating times and high power output.

Looking ahead, further research and development are crucial to overcome the existing challenges and pave the way for the widespread adoption of metal-air batteries in various applications. Continued advancements in electrode materials, electrolyte design, and battery fabrication techniques are essential for realizing their full potential.

Read more about Emerging Technologies in Energy Storage: Beyond Lithium Ion

Hot Recommendations

- Offshore Wind for Industrial Power

- Agrivoltaics: Dual Land Use with Solar Energy Advancements: Sustainable Farming

- Hydrogen as an Energy Storage Medium: Production, Conversion, and Usage

- Utility Scale Battery Storage: Successful Project Case Studies

- The Role of Energy Storage in Grid Peak Shaving

- The Role of Startups in Renewable Energy

- The Role of Blockchain in Decentralization of Energy Generation

- The Future of Wind Energy Advancements in Design

- Synchronous Condensers and Grid Inertia in a Renewable Energy Grid

- Corporate Renewable Procurement for Government Agencies