Geothermal Power Plant Technologies: Flash, Dry Steam, and Binary Cycle

Direct Steam Generation and its Advantages

Dry steam power plants, a specialized type of thermal power plant, utilize the direct generation of steam from the heat source, typically a high-temperature furnace. This method offers several advantages over other approaches, most notably in terms of efficiency and reduced complexity. The direct generation process often bypasses intermediate processes, leading to a more streamlined and potentially more cost-effective system.

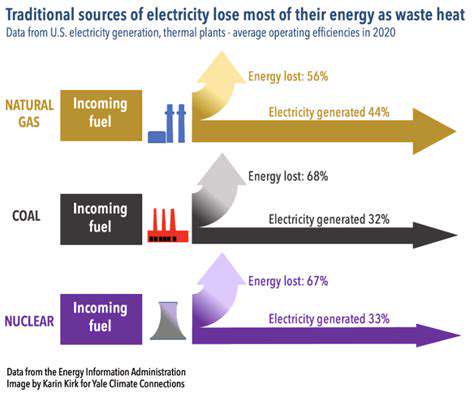

One key advantage is the potential for higher thermal efficiency. The direct generation of steam avoids the energy losses inherent in transferring heat to a secondary fluid, which is a common practice in some other power plant types. This direct approach can translate into substantial savings in fuel consumption and operating costs.

Fuel Types and Considerations

Dry steam power plants can utilize a variety of fuels, including coal, biomass, and natural gas, with the most suitable choice often determined by local availability and economic factors. Careful consideration of fuel characteristics is critical for optimal plant design and operation, as different fuels have varying combustion properties and require different furnace designs.

The selection of fuel plays a significant role in environmental impact. Biomass, for example, can be a sustainable fuel source when sourced responsibly, while coal and natural gas have different environmental profiles. Choosing the right fuel necessitates careful environmental assessments and adherence to regulations.

Turbine Systems and Design

The turbines in dry steam plants are specifically designed to handle the high-pressure, high-temperature steam produced directly. These turbines are crucial components, as they convert the thermal energy of the steam into mechanical energy, driving the generator.

The design of the turbine system is critical for maximum efficiency and reliability. Factors like blade geometry, material selection, and sealing mechanisms must be carefully considered to withstand the extreme operating conditions and maximize power output. Proper maintenance is also vital for prolonged turbine performance.

Plant Safety and Operational Procedures

Dry steam power plants, due to the inherent high temperatures and pressures involved, require stringent safety protocols and operational procedures. Regular inspections, maintenance checks, and adherence to safety regulations are paramount to prevent accidents and ensure the long-term integrity of the plant.

Safety is paramount in a dry steam plant, and proper training for personnel is essential. Emergency procedures and contingency plans must be well-defined and regularly practiced to minimize risks and ensure a safe working environment. The high-pressure steam system necessitates strict adherence to safety measures.

Environmental Impact and Sustainability

Dry steam power plants, like all thermal power plants, have an environmental impact. Considerations include greenhouse gas emissions, water consumption, and waste disposal. Efforts to minimize these impacts are crucial to ensure responsible and sustainable operation.

Minimizing the environmental footprint of dry steam plants requires careful planning and implementation of emission control technologies. Sustainable fuel sources, combined with efficient operation and waste management strategies, can significantly reduce the overall environmental impact of these plants.

Economic Viability and Cost Analysis

The economic viability of a dry steam power plant depends on various factors, including fuel costs, construction expenses, operating costs, and potential revenue streams. A comprehensive cost-benefit analysis is essential to determine the feasibility of such a project.

Capital costs, operational expenses, and projected returns on investment are all crucial factors to consider. Market analysis, fuel availability, and government regulations play a significant role in determining the financial attractiveness of a dry steam power plant project.

Maintenance and Operational Costs

Maintaining the high-pressure equipment and ensuring the continuous operation of a dry steam power plant requires significant resources. Routine maintenance, repairs, and upgrades are necessary for the plant's long-term efficiency and reliability.

Predictive maintenance strategies and diligent monitoring are essential to minimize downtime and prevent costly repairs. Keeping track of equipment health and anticipating potential failures through monitoring and analysis can significantly reduce operational costs.

A deep understanding of grasping extends far beyond the simple act of holding an object. It encompasses the intricate interplay of sensory input, motor control, and cognitive processes. Grasping, in its most fundamental sense, is a complex skill that involves more than just the physical act of encircling an object; it's a crucial component of interaction with the environment. Furthermore, this understanding is essential for developing sophisticated robotic systems capable of manipulating objects with precision and dexterity.

Binary Cycle Power Plants: Efficient Utilization of Lower-Temperature Resources

Understanding Binary Cycle Power Plants

Binary cycle power plants represent a significant advancement in the field of energy production, particularly in utilizing lower-grade heat sources. These systems are designed to efficiently capture and convert thermal energy from various sources, including geothermal, industrial waste heat, and solar thermal, into electricity. This approach differs from traditional steam-based power plants by employing two thermodynamic cycles, thus the name binary. Understanding the core principles behind these systems is crucial to appreciating their potential in a sustainable energy future.

The Two-Cycle Process

The key to binary cycle power plants lies in their dual-cycle approach. A low-temperature heat source heats a working fluid with a lower boiling point. This working fluid then vaporizes and drives a turbine, generating electricity. The resulting condensed fluid is then reheated and the cycle repeats. This process allows for the conversion of heat from lower temperature sources that would otherwise be unusable in traditional steam power plants, significantly expanding the range of potential energy sources.

Advantages of Binary Cycle Power Plants

Binary cycle power plants offer several compelling advantages over conventional power plants. They are particularly well-suited for applications with lower-grade heat sources, such as geothermal resources with temperatures below 200°C. This allows for greater resource utilization, minimizing waste and maximizing energy capture. Furthermore, their smaller footprint and lower capital costs make them attractive options for distributed energy generation.

Another significant advantage is improved efficiency compared to traditional systems when operating with low-temperature sources. This heightened efficiency translates to reduced fuel consumption and lower environmental impact.

Applications in Various Industries

The applications of binary cycle power plants are diverse and span various industries. They are increasingly utilized in geothermal energy projects, where the lower temperatures of some geothermal reservoirs make them ideal candidates. Moreover, industrial facilities generating waste heat can harness this heat through binary cycle systems, reducing operational costs and minimizing environmental impact. The integration of solar thermal energy with binary cycles is also gaining traction, promising a sustainable and renewable energy solution.

Challenges and Future Outlook

Despite the numerous advantages, binary cycle power plants face challenges, such as the selection of appropriate working fluids for different applications. Optimization of the thermodynamic cycles for specific temperature ranges is key to maximizing efficiency. Furthermore, the cost-effectiveness of these systems, particularly in comparison to traditional alternatives, remains a critical factor that needs to be considered. Future research and development are focused on optimizing the selection of working fluids, improving cycle efficiency, and reducing the overall cost of these systems to unlock their full potential.

Environmental Impact and Sustainability

The environmental impact of binary cycle power plants is generally positive compared to other energy generation methods. Their ability to utilize lower-grade heat sources minimizes waste and reduces reliance on high-temperature heat sources. Furthermore, the utilization of renewable energy sources like geothermal and solar thermal energy for driving these systems further enhances their environmental profile. The focus on these systems aligns with the broader push toward sustainable energy solutions and reduced greenhouse gas emissions, offering a promising path toward a greener energy future.

Comparative Analysis and Future Trends

Flash Steam Systems: A Deep Dive

Flash steam systems are a cornerstone of geothermal power generation, leveraging the high-temperature, high-pressure steam produced deep within the Earth. These systems are particularly effective in areas with high-enthalpy geothermal resources, where the steam can be directly extracted and used to drive turbines. Understanding the intricacies of flash steam extraction, including the separation of steam from the geothermal fluid, is crucial for optimizing efficiency and minimizing operational costs. Proper pressure management and careful consideration of the fluid's composition are critical aspects to ensure efficient power generation and minimize environmental impact.

The initial stages of flash steam extraction often involve a series of separators and flash chambers. These components play a critical role in the thermodynamic process, allowing for the separation of steam from the remaining geothermal fluid. The separated steam is then directed towards turbines to generate electricity, while the cooler, condensed fluid is often reinjected back into the geothermal reservoir, maintaining reservoir pressure and minimizing environmental impacts. The operational efficiency of a flash steam system is heavily dependent on the accurate prediction and management of thermodynamic parameters, like pressure and temperature, throughout the entire process.

Binary Cycle Systems: A Promising Alternative

Binary cycle systems represent a significant advancement in geothermal power generation, offering a more efficient approach for lower-temperature geothermal resources. Instead of directly using the geothermal fluid to drive turbines, binary cycle systems utilize a working fluid with a lower boiling point. This working fluid is heated by the geothermal fluid, vaporizing and driving a turbine. This approach allows for the utilization of geothermal resources with lower temperatures than those suitable for flash steam systems, expanding the potential applications of geothermal energy.

A key advantage of binary cycle systems is their enhanced efficiency compared to flash steam systems in lower-temperature environments. The use of a separate working fluid minimizes heat loss and maximizes energy conversion. Moreover, the lower temperatures involved in binary cycles often translate to reduced corrosion and operational issues associated with high-temperature components. This makes binary cycle systems a potentially valuable option for regions with abundant lower-temperature geothermal resources.

The selection of the appropriate working fluid is crucial for optimization. Different working fluids exhibit varying boiling points and thermodynamic properties, impacting the system's efficiency and operational parameters. Careful consideration must be given to the specific geothermal resource characteristics and the desired output to choose the most suitable working fluid.

Future Trends and Innovations

The geothermal power sector is constantly evolving, with ongoing research and development focused on improving efficiency, reducing costs, and expanding the applicability of geothermal technologies. One promising area of investigation is the development of enhanced geothermal systems (EGS), which focus on fracturing deep underground rock formations to create pathways for geothermal fluids, thereby expanding the reach of geothermal resources. This technology is still under development, but it holds the potential to unlock vast geothermal energy resources in locations previously deemed unsuitable.

Another significant trend is the integration of geothermal energy with other renewable energy sources, like solar and wind, to create hybrid power systems. This integration can help to stabilize power grids and provide a more reliable and sustainable energy mix. Furthermore, advancements in materials science are leading to the development of more durable and cost-effective components for geothermal power plants, ultimately lowering operational costs and increasing overall efficiency.

The potential of geothermal energy is vast, and ongoing research and innovation are paving the way for more efficient, cost-effective, and environmentally friendly solutions for power generation. Further exploration of these innovative technologies will be crucial in unlocking the full potential of geothermal energy and ensuring its role in a sustainable energy future.

Read more about Geothermal Power Plant Technologies: Flash, Dry Steam, and Binary Cycle

Hot Recommendations

- Offshore Wind for Industrial Power

- Agrivoltaics: Dual Land Use with Solar Energy Advancements: Sustainable Farming

- Hydrogen as an Energy Storage Medium: Production, Conversion, and Usage

- Utility Scale Battery Storage: Successful Project Case Studies

- The Role of Energy Storage in Grid Peak Shaving

- The Role of Startups in Renewable Energy

- The Role of Blockchain in Decentralization of Energy Generation

- The Future of Wind Energy Advancements in Design

- Synchronous Condensers and Grid Inertia in a Renewable Energy Grid

- Corporate Renewable Procurement for Government Agencies