How Legacy Automakers Are Competing in the EV Space

The Shifting Sands of Competition

The automotive industry, long dominated by internal combustion engine (ICE) manufacturers, is undergoing a seismic shift. Electric vehicles (EVs) are rapidly gaining popularity, creating a new competitive landscape where established players are forced to adapt or risk being left behind. This transition isn't just about swapping gasoline for electricity; it's about fundamentally rethinking manufacturing processes, supply chains, and even the very nature of the vehicle itself. The traditional hierarchy of players is being challenged, and new competitors, both established and emerging, are vying for market share in this burgeoning EV revolution.

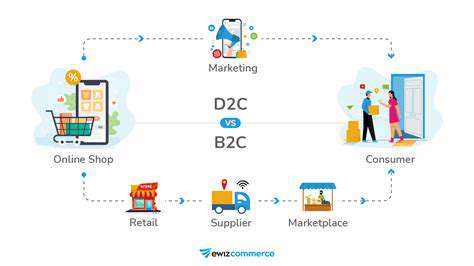

This shift isn't simply a matter of replacing an old technology with a new one. The entire ecosystem surrounding vehicles is changing. From battery production to charging infrastructure, the entire supply chain is being reshaped. Existing players must invest heavily in new technologies and adapt to a market driven by different consumer needs and preferences. Successfully navigating this transformation will require not only technological prowess but also a deep understanding of the evolving consumer landscape.

Adapting to a New Era of Mobility

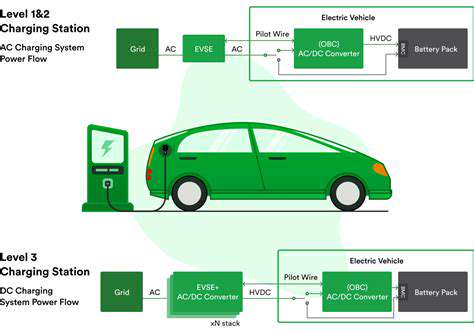

For established automakers, the transition to EVs is a significant undertaking. They face challenges in adapting their existing infrastructure, acquiring new technologies, and attracting the necessary talent to develop and manufacture electric vehicles. Furthermore, the economics of EVs are different from those of ICE vehicles, requiring a significant shift in their business models. This includes considerations about battery sourcing, charging network development, and the potential for new business models based on shared mobility and vehicle-to-grid (V2G) technologies.

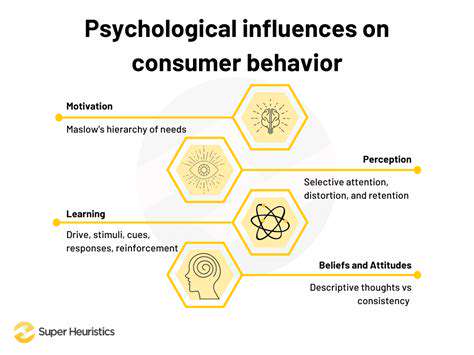

Beyond the technical aspects, there's a crucial element of consumer perception to consider. Building trust and confidence in electric vehicles is paramount. Addressing range anxiety, charging infrastructure availability, and the overall driving experience are vital for convincing consumers to make the switch. Established players need to not only offer compelling EV models but also foster an ecosystem that supports their adoption. This goes beyond simply producing the cars; it includes educating customers and building a sense of community around the new technology.

The EV revolution isn't just about cars; it's about a fundamental change in how we think about transportation. Existing players must adapt their strategies and embrace innovation to navigate this new competitive landscape. Failure to do so will result in significant market share loss and a diminished position in the future of automotive. This is a period of intense pressure and opportunity, demanding agility and a willingness to embrace the unknown.

Beyond the Batteries: Integrating a Holistic Approach

Reimagining the Driving Experience

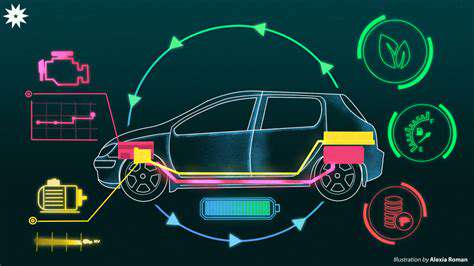

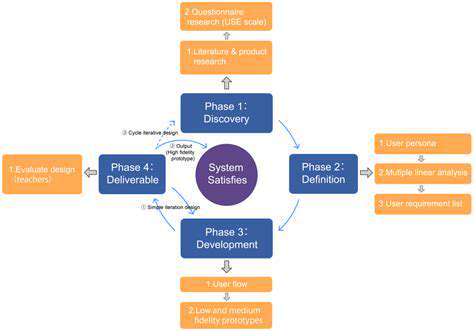

Beyond simply replacing internal combustion engines with electric motors, legacy automakers are focusing on a holistic approach to the driving experience. This involves not just the technology itself, but also the design, the user interface, and the overall feeling of being behind the wheel. Imagine a car that anticipates your needs, seamlessly integrates with your lifestyle, and offers a level of comfort and sophistication previously unseen in the automotive industry. This holistic approach is crucial for attracting a new generation of drivers and ensuring the long-term success of these companies in the electric vehicle market.

The emphasis on personalization and a more intuitive interface is a key element of this reimagining. Features like adaptive suspension, advanced driver-assistance systems (ADAS), and personalized infotainment systems are being integrated to offer a truly bespoke driving experience that caters to individual preferences. This goes beyond simple functionality and aims to create a truly engaging and enjoyable experience for the driver.

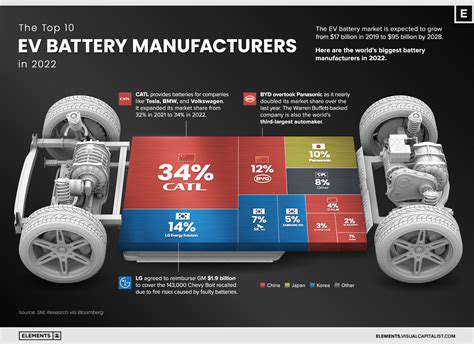

Strategic Partnerships and Supply Chain Diversification

Successfully transitioning to electric vehicles demands a robust and reliable supply chain. Legacy automakers are actively forging strategic partnerships with battery manufacturers, component suppliers, and charging infrastructure providers to ensure a smooth transition. This proactive approach is vital to securing the necessary materials, expertise, and infrastructure to support the expanding electric vehicle market, and to mitigate potential supply chain disruptions.

Investing in Research and Development

The future of automotive technology is not just about electric vehicles; it's about the integration of advanced technologies, from AI to autonomous driving. Significant investments in research and development are crucial for innovation. These investments are not only focused on developing more efficient and powerful batteries but also on creating a future where vehicles can adapt to their environment, learn from their usage, and ultimately, enhance the driving experience.

These investments also encompass the development of advanced driver-assistance systems (ADAS) and autonomous driving technologies. This commitment to innovation is essential for staying ahead of the curve in a rapidly evolving automotive landscape.

Addressing Public Concerns and Building Trust

The transition to electric vehicles is not without its challenges. Public concerns about range anxiety, charging infrastructure, and the environmental impact of battery production need to be addressed. Legacy automakers must proactively engage with these concerns, demonstrating their commitment to sustainability and providing transparent information about the entire lifecycle of their electric vehicles.

Building trust with consumers is essential. This involves showcasing the environmental benefits of electric vehicles, addressing concerns about charging accessibility, and providing clear and reliable information about battery technology and its longevity. Transparency and proactive communication are key to fostering consumer confidence and driving adoption.

A New Era of Mobility and Sustainability

The shift to electric vehicles represents a fundamental change in the automotive industry. Legacy automakers are not just developing new vehicles; they are actively shaping the future of mobility, aiming to create a more sustainable and environmentally friendly transportation system. This involves not only designing vehicles that minimize their environmental footprint but also integrating sustainable practices throughout their entire operations, from manufacturing to recycling.

This transformation also encompasses a larger societal shift, one that prioritizes environmental responsibility and technological advancement. Legacy automakers are positioned to lead this change, demonstrating a commitment to both innovation and sustainability.

Manufacturing Challenges and Adaptations

Adapting to Electric Vehicle Demands

The shift to electric vehicles (EVs) presents a significant challenge for legacy automakers. They must rapidly adapt their manufacturing processes to accommodate the unique requirements of batteries, electric motors, and specialized charging infrastructure. This includes significant capital investments in new equipment, training programs for existing workers, and potentially the acquisition or development of entirely new manufacturing facilities. Successfully navigating this transition is crucial for maintaining market share and profitability in the face of aggressive competition from established and emerging EV manufacturers.

Furthermore, the supply chain for EV components is often more complex and geographically dispersed than for traditional internal combustion engine (ICE) vehicles. This necessitates careful management of global logistics, sourcing, and risk mitigation strategies to ensure consistent and reliable supply. The reliance on critical materials like lithium and cobalt also introduces geopolitical and environmental considerations that require proactive and responsible sourcing strategies.

Optimizing Existing Infrastructure

Legacy automakers often possess extensive existing manufacturing facilities and infrastructure designed for ICE vehicles. Converting these facilities to support EV production requires significant investment and careful planning. This involves retooling existing assembly lines, integrating new technologies, and ensuring compatibility with existing supply chains. The process of optimizing these facilities can be complex and costly, requiring meticulous analysis of current capabilities and future needs to maximize efficiency and minimize disruption.

Existing workforce training and development programs must also be adapted to equip employees with the skills necessary for EV production. This includes training on battery management systems, electric motor operation, and the safe handling of high-voltage components. Failure to adequately address these training needs could lead to significant bottlenecks and production delays during the transition.

Addressing Supply Chain Disruptions

The global supply chain for automotive components is highly complex, and disruptions can have a significant impact on production schedules and costs. Legacy automakers must develop more resilient and diversified supply chains to ensure stability in the face of potential future disruptions. This may involve exploring new sources for materials, diversifying manufacturing locations, and implementing robust risk management strategies.

The increasing demand for critical materials like lithium and cobalt presents another challenge for legacy automakers. The availability of these materials, and the associated environmental and ethical considerations, must be carefully evaluated. Failure to address these supply chain issues could result in production delays, increased costs, and significant reputational damage in the long run.

Maintaining Quality Control and Safety Standards

Maintaining consistent high-quality standards and robust safety protocols throughout the EV production process is paramount for legacy automakers. The complexity of EV components, including batteries and electric motors, necessitates rigorous testing and quality control measures to ensure reliability and durability. This often requires new technologies and specialized equipment to meet the increasingly stringent safety standards associated with battery technology.

Moreover, legacy automakers must adapt their quality control procedures to handle the unique challenges associated with electric vehicle manufacturing. This includes stringent testing for battery performance, charging safety, and the overall functionality of the vehicle's electrical systems. Failure to maintain these standards could lead to significant safety risks and potentially harmful consequences for consumers.

The real magic? You don’t have to lift a finger after the initial setup. The transfers happen like clockwork, creating a rhythm that keeps your savings growing without you even thinking about it. This isn’t just about money—it’s about building a mindset of control and confidence with your finances.

Read more about How Legacy Automakers Are Competing in the EV Space

Hot Recommendations

- Offshore Wind for Industrial Power

- Agrivoltaics: Dual Land Use with Solar Energy Advancements: Sustainable Farming

- Hydrogen as an Energy Storage Medium: Production, Conversion, and Usage

- Utility Scale Battery Storage: Successful Project Case Studies

- The Role of Energy Storage in Grid Peak Shaving

- The Role of Startups in Renewable Energy

- The Role of Blockchain in Decentralization of Energy Generation

- The Future of Wind Energy Advancements in Design

- Synchronous Condensers and Grid Inertia in a Renewable Energy Grid

- Corporate Renewable Procurement for Government Agencies