The Future of Corporate Renewable Procurement

Addressing Supply Chain Challenges and Opportunities

Understanding the Scope of Supply Chain Disruptions

Supply chain disruptions are no longer a rare occurrence but a persistent challenge across industries. These disruptions, ranging from natural disasters to geopolitical instability, can have significant and cascading effects on businesses, impacting everything from production to customer delivery. Understanding the multifaceted nature of these issues is crucial for effective mitigation strategies.

Identifying the specific points of vulnerability within your supply chain is paramount. This requires detailed mapping of each stage, from raw material sourcing to final product delivery. Analyzing historical data and industry trends is critical to anticipate potential disruptions and develop proactive solutions.

Optimizing Inventory Management

Effective inventory management is essential for mitigating supply chain risks. Maintaining optimal stock levels, balancing storage costs and potential obsolescence, is crucial for ensuring timely product availability. This involves implementing sophisticated inventory forecasting models, considering lead times, and embracing real-time data analytics to adapt to changing demands.

Proactive inventory management strategies, including just-in-time inventory systems, can help reduce holding costs and enhance responsiveness to fluctuations in demand. Regularly reviewing and adjusting inventory levels based on market trends and supplier reliability is critical.

Strengthening Supplier Relationships

Building strong, reliable partnerships with suppliers is vital for resilience. Diversifying supplier bases and establishing robust communication channels can help mitigate the impact of single points of failure. Developing contingency plans with key suppliers to address potential disruptions is crucial.

Cultivating long-term relationships with suppliers fosters trust and mutual understanding, leading to better collaboration and proactive problem-solving. Transparent communication and shared risk assessments are essential for effective risk mitigation.

Embracing Technology for Efficiency

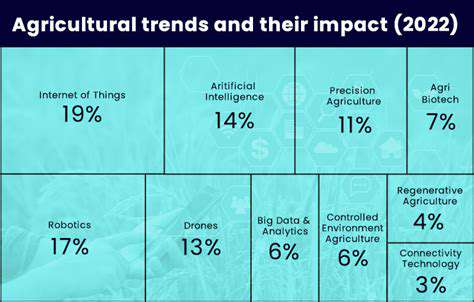

Technology plays a critical role in streamlining supply chains and enhancing visibility. Implementing advanced technologies like automation, AI, and data analytics can improve efficiency, predictive capabilities, and real-time tracking. These tools can provide insights into potential bottlenecks and allow for rapid response to changing circumstances.

Leveraging technology to gain real-time visibility into inventory levels, production processes, and transportation logistics allows for proactive adjustments and minimizes potential disruptions. This data-driven approach empowers businesses to make informed decisions and optimize their supply chains.

Developing Robust Contingency Plans

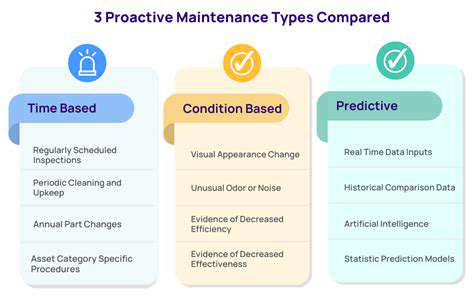

Developing comprehensive contingency plans is a cornerstone of supply chain resilience. These plans should outline specific actions to be taken in response to various potential disruptions, such as natural disasters, pandemics, or geopolitical events. Establishing clear communication protocols and designating roles for crisis response is critical.

Having a well-defined plan in place allows businesses to respond swiftly and effectively to unforeseen circumstances. Regularly testing and updating these plans is crucial to ensure their effectiveness and adaptability.

Investing in Supply Chain Security

Securing critical infrastructure and data is paramount for maintaining supply chain integrity. Implementing robust cybersecurity measures to protect against cyberattacks and data breaches is essential. This includes investing in secure communication systems and regularly assessing vulnerabilities.

Protecting sensitive supply chain data and infrastructure is not merely a best practice but a critical security imperative. Proactive measures, such as threat modeling and incident response planning, are vital to mitigate risks.

Promoting Collaboration and Transparency

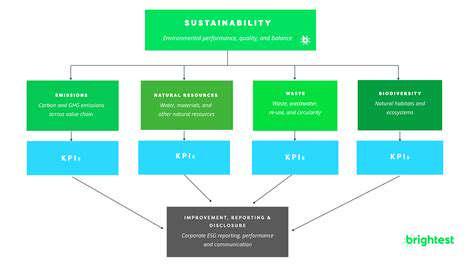

Collaboration and transparency are crucial for effective supply chain management. Working closely with stakeholders, including suppliers, manufacturers, and distributors, fosters a shared understanding of challenges and opportunities. Encouraging open communication and data sharing can lead to more efficient problem-solving.

Promoting transparency and collaboration throughout the supply chain builds trust and resilience. This approach facilitates the identification and resolution of issues more quickly and effectively, leading to a more robust and adaptable supply chain.

Read more about The Future of Corporate Renewable Procurement

Hot Recommendations

- Offshore Wind for Industrial Power

- Agrivoltaics: Dual Land Use with Solar Energy Advancements: Sustainable Farming

- Hydrogen as an Energy Storage Medium: Production, Conversion, and Usage

- Utility Scale Battery Storage: Successful Project Case Studies

- The Role of Energy Storage in Grid Peak Shaving

- The Role of Startups in Renewable Energy

- The Role of Blockchain in Decentralization of Energy Generation

- The Future of Wind Energy Advancements in Design

- Synchronous Condensers and Grid Inertia in a Renewable Energy Grid

- Corporate Renewable Procurement for Government Agencies