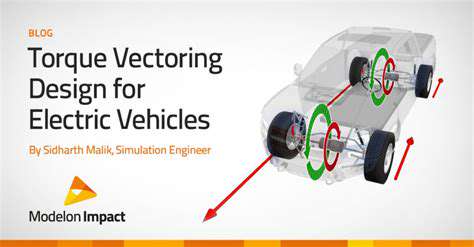

The Role of Torque Vectoring in Improving EV Handling

Torque vectoring systems, crucial in enhancing the cornering capabilities of electric vehicles (EVs), actively manage torque distribution between the wheels. This sophisticated technology allows for precise control over wheel-torque application, leading to improved traction and stability during maneuvers. By adjusting the amount of torque delivered to each wheel individually, torque vectoring systems can optimize the vehicle's dynamic response, enabling drivers to confidently navigate corners at higher speeds and with greater precision.

Improved Traction and Stability

In cornering scenarios, torque vectoring systems play a vital role in optimizing traction and stability. By precisely managing torque distribution, these systems can maintain a more controlled and predictable trajectory, especially on slippery surfaces. This enhanced traction translates into a more confident and stable driving experience, reducing the risk of loss of control and improving overall safety.

The ability to modulate torque at each wheel allows the system to counteract the tendency of the vehicle to slide or lose grip during a turn, significantly improving stability. This is particularly important in electric vehicles, where the instant torque delivery of the electric motor can sometimes lead to excessive wheelspin if not managed effectively.

Enhanced Handling Dynamics

Torque vectoring systems significantly enhance the handling dynamics of EVs by promoting a more responsive and predictable driving experience. The precise control over wheel torque allows for more controlled cornering, minimizing the tendency for understeer or oversteer. This translates into a sharper, more engaging driving experience, allowing drivers to confidently explore the vehicle's limits without compromising stability.

Reduced Cornering Time

By optimizing torque distribution, torque vectoring systems can potentially reduce the time it takes for an EV to complete a corner. This is achieved by ensuring that the wheels are always delivering the optimal amount of torque to maintain traction and prevent loss of momentum. Reduced cornering time translates into a more efficient and responsive handling characteristic, enhancing the overall driving experience.

Impact on Electric Vehicle Dynamics

Electric vehicles, with their instant torque delivery, can benefit greatly from torque vectoring systems. The responsiveness of electric motors can sometimes lead to a less predictable driving experience in corners, particularly at higher speeds. Torque vectoring mitigates these issues by allowing for a more controlled and precise distribution of torque, resulting in improved cornering performance and overall vehicle dynamics.

Real-World Applications and Benefits

Torque vectoring systems are becoming increasingly common in high-performance EVs, offering drivers a significant advantage in terms of handling, stability, and cornering performance. By optimizing torque distribution, these systems enhance the vehicle's overall responsiveness and controllability, making driving more enjoyable and engaging. The benefits are particularly noticeable in demanding driving conditions, such as winding roads or tight corners.

Future of Torque Vectoring in EVs

The future of torque vectoring in electric vehicles looks promising. Ongoing advancements in electric motor technology and control systems are paving the way for even more sophisticated and effective torque vectoring systems. This is expected to further enhance the handling capabilities of EVs, making them more dynamic and responsive while maintaining high levels of stability and safety. This evolution will contribute to a future where electric vehicles offer not only an environmentally friendly option but also a driving experience that rivals or even surpasses that of traditional internal combustion engine vehicles.

Beyond Cornering: Torque Vectoring's Role in Traction and Stability

Torque Vectoring: Enhancing Traction

Torque vectoring systems, a crucial component in modern vehicles, go beyond simply managing engine torque. They actively distribute torque to each wheel, enabling more precise control over the vehicle's direction and movement. This proactive approach to traction management allows for superior grip on various surfaces, especially in challenging conditions like slippery roads or uneven terrain. By adjusting the torque applied to individual wheels, torque vectoring systems can optimize wheel spin and maintain stability during acceleration and cornering maneuvers.

Imagine a car navigating a winding mountain road. Without torque vectoring, the car might struggle to maintain its trajectory, potentially losing traction and control. Torque vectoring, however, actively adjusts the torque distribution to each wheel, ensuring that the wheels with the most grip receive the necessary torque to maintain control, thus preventing wheel slip and enhancing the vehicle's overall stability.

Improving Stability During Dynamic Maneuvers

Torque vectoring plays a pivotal role in enhancing vehicle stability during dynamic maneuvers like braking and cornering. By adjusting the torque distribution, it helps to counteract the tendency of the vehicle to oversteer or understeer. This active intervention allows for a more controlled and predictable driving experience, particularly at higher speeds or in demanding driving conditions.

Precise control during braking is another key benefit. Torque vectoring can adjust the braking forces on individual wheels, reducing the likelihood of a skid or loss of control. This is particularly valuable in emergency braking situations, where milliseconds can make the difference between a controlled stop and a potentially dangerous loss of control.

Torque Vectoring: A Deeper Dive into Functionality

The core functionality of torque vectoring lies in its ability to precisely manage the torque applied to each wheel. This sophisticated system often involves advanced sensors and actuators that continuously monitor road conditions, vehicle speed, and driver input to dynamically adjust the torque distribution. This real-time feedback loop allows for immediate responses to changing conditions, ensuring optimal traction and stability.

Beyond the Basics: The Technological Advancements

Modern torque vectoring systems are constantly evolving, incorporating new technologies and sophisticated algorithms. These advancements are focused on maximizing the system's responsiveness and effectiveness in various driving scenarios. From advanced sensor technology to improved control algorithms, these developments contribute to a smoother, more stable, and ultimately, more enjoyable driving experience. The future of torque vectoring promises even greater precision and adaptability to the ever-changing demands of modern driving.

The integration of advanced driver-assistance systems (ADAS) with torque vectoring systems is another key area of development. Combining these technologies can lead to even more sophisticated control and safety features, making vehicles more capable and responsive to driver input and environmental conditions.