The Strategic Advantage: Generative AI in Enterprise Supply Chains

Optimizing Inventory Management & Logistics

Optimizing Inventory Accuracy

Maintaining accurate inventory records is crucial for effective inventory management. Inaccurate counts can lead to significant financial losses, from lost sales due to stockouts to unnecessary holding costs for excess inventory. Implementing robust inventory tracking systems, whether manual or automated, is essential to ensure that data reflects the actual on-hand stock. Regular cycle counting and physical inventory audits are vital for verifying the accuracy of the recorded data and identifying discrepancies promptly.

Thorough record-keeping practices, including detailed documentation of receipts, shipments, and transfers, are also key components of achieving inventory accuracy. This detailed record-keeping helps in identifying potential issues and pinpointing the root causes of discrepancies.

Streamlining the Procurement Process

Efficient procurement is critical to optimizing inventory management. Strategic sourcing and negotiations with suppliers can significantly impact inventory costs. By analyzing historical data and market trends, businesses can identify the most cost-effective suppliers and negotiate favorable terms, thereby reducing the overall cost of goods.

Establishing clear procurement policies and procedures helps ensure consistency and control over the acquisition of inventory. These policies should address factors such as order quantities, lead times, and supplier relationships.

Implementing Effective Forecasting Techniques

Accurate forecasting is vital for predicting future demand and aligning inventory levels accordingly. By analyzing historical sales data, market trends, and external factors, businesses can develop realistic demand forecasts.

Implementing sophisticated forecasting models, such as time series analysis or machine learning algorithms, can enhance the accuracy of predictions. This helps in optimizing inventory levels, minimizing stockouts, and preventing excess inventory.

Optimizing Storage and Handling

Efficient storage and handling practices are essential for maximizing warehouse space and minimizing handling costs. Optimizing storage space and implementing appropriate shelving or racking systems can maximize the use of available warehouse space.

Utilizing automated storage and retrieval systems (AS/RS) can further enhance efficiency and reduce labor costs. Employing proper handling techniques, such as using ergonomic equipment and standardized procedures, minimizes the risk of damage and loss during the handling process.

Managing Inventory Turnover

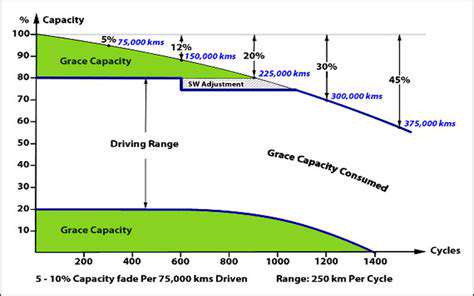

Monitoring inventory turnover rates is a critical aspect of inventory management. A high inventory turnover rate typically indicates that goods are moving quickly through the supply chain, leading to efficient use of capital and reduced holding costs.

Calculating the inventory turnover ratio and comparing it to industry benchmarks can help businesses identify areas for improvement. A low turnover rate might suggest overstocking, while a very high turnover rate could signal potential stockouts.

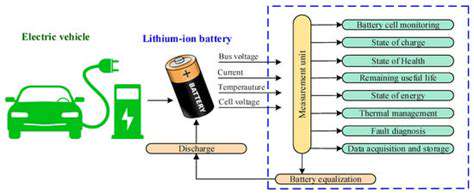

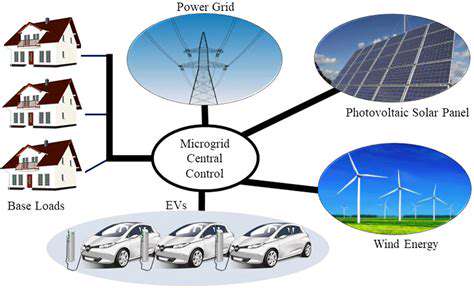

Utilizing Technology for Inventory Management

Leveraging inventory management software and systems offers significant advantages in optimizing inventory processes. These systems provide real-time visibility into inventory levels, enabling informed decision-making. Automated inventory tracking and management tools can significantly reduce manual data entry errors and improve data accuracy.

Integrating inventory management systems with other business applications, such as accounting and sales, creates a unified view of the entire supply chain. This improved visibility facilitates better forecasting, planning, and decision-making.

Inventory Control and Risk Mitigation

Establishing clear procedures for receiving, storing, and shipping inventory is essential to maintaining control over the entire process. Implementing strict quality control measures at each stage, from receiving to shipping, ensures the delivery of high-quality products to customers.

Developing contingency plans for potential disruptions, such as supply chain issues or unexpected demand surges, can mitigate risks. Building strong relationships with suppliers and establishing backup sourcing options are crucial strategies for minimizing disruptions.

Automating Complex Processes & Enhancing Efficiency

Automating Repetitive Tasks

Automating complex processes is a powerful way to boost efficiency and reduce errors in various industries. By automating repetitive tasks, companies can free up valuable human resources to focus on more strategic and creative work. This not only improves productivity but also allows for a more streamlined workflow, reducing the time it takes to complete projects and tasks. Efficient automation can significantly improve overall business outcomes.

Imagine a scenario where a large company processes thousands of invoices each month. Manually processing each invoice is a time-consuming and error-prone process. Implementing an automated invoice processing system can drastically reduce the time required for this task, allowing the company to focus on other important activities. This automation can also help avoid human error, ensuring accuracy and reducing the potential for financial discrepancies.

Improving Accuracy & Reducing Errors

Automation plays a vital role in minimizing errors associated with manual data entry and repetitive tasks. By replacing human intervention with precise algorithms and software, organizations can significantly improve the accuracy and reliability of their processes. This accuracy translates directly to better decision-making and more precise outcomes.

Complex processes often involve numerous steps and data points, increasing the likelihood of human error. Automating these processes eliminates the risk of errors introduced by human fatigue, distraction, or simple mistakes. This leads to a more robust and consistent output, which in turn, enhances the credibility and reliability of the entire process.

Automated systems can be programmed to adhere strictly to predefined rules and parameters, ensuring that every step is performed with the utmost precision. This eliminates the potential for subjective interpretation and inconsistencies that are common in manual processes. Maintaining precise data is crucial for any organization striving for excellence and dependability.

Enhancing Scalability & Flexibility

Automated systems are inherently scalable, adapting easily to changing demands and growing workloads. This adaptability is critical for organizations facing fluctuating business needs. As volumes increase, automated systems can handle the increased load without significant adjustments to staffing or infrastructure. This adaptability is key to maintaining consistent performance as the business evolves.

Automation provides a significant boost to the flexibility of an organization's processes. If business requirements change, automated systems can be reprogrammed or reconfigured to accommodate new procedures and workflows. This flexibility is a major advantage in today's dynamic business environment, allowing for quick responses to market changes and evolving customer needs. The ability to adjust to new demands is essential for long-term success in the face of constant change.

Read more about The Strategic Advantage: Generative AI in Enterprise Supply Chains

Hot Recommendations

- Offshore Wind for Industrial Power

- Agrivoltaics: Dual Land Use with Solar Energy Advancements: Sustainable Farming

- Hydrogen as an Energy Storage Medium: Production, Conversion, and Usage

- Utility Scale Battery Storage: Successful Project Case Studies

- The Role of Energy Storage in Grid Peak Shaving

- The Role of Startups in Renewable Energy

- The Role of Blockchain in Decentralization of Energy Generation

- The Future of Wind Energy Advancements in Design

- Synchronous Condensers and Grid Inertia in a Renewable Energy Grid

- Corporate Renewable Procurement for Government Agencies