Why EV Battery Technology Will Define the Next Decade

Modern transportation's transformation hinges on breakthroughs in battery chemistry. Cutting-edge research focuses on nickel-rich cathodes and lithium-metal anodes, pushing energy density boundaries while maintaining safety standards. These innovations directly address consumer concerns about electric vehicle (EV) range limitations and charging times.

Electrolyte development represents another critical frontier. Next-generation formulations demonstrate remarkable thermal stability, significantly reducing fire risks while maintaining ionic conductivity. Such improvements prove essential as battery packs grow larger to meet increasing energy demands.

Cost-Effective Production: Driving Down the Price of Batteries

Manufacturing innovations are revolutionizing battery economics. Process optimizations and alternative material sourcing create unprecedented cost reductions without compromising quality. These advancements make EVs increasingly competitive with internal combustion vehicles.

Production scale effects now deliver tangible benefits. Every doubling of manufacturing capacity yields consistent price drops, accelerating EV adoption curves worldwide. This virtuous cycle continues to reshape automotive market dynamics.

Enhanced Safety Features: Mitigating Risks

Modern battery systems incorporate multiple protective layers. Sophisticated thermal management systems actively monitor and regulate cell temperatures, while advanced battery enclosures contain potential thermal events. These innovations have dramatically improved real-world safety records.

Battery management systems (BMS) now employ predictive algorithms that anticipate potential issues before they escalate. Continuous monitoring of individual cell voltages and temperatures ensures optimal performance throughout the battery's lifecycle.

Improved Charging Infrastructure: Enabling Convenient Usage

The charging experience continues evolving rapidly. Next-generation 350kW stations can add 200 miles of range in under 15 minutes, matching traditional refueling times. Strategic placement along major routes addresses remaining range anxiety concerns.

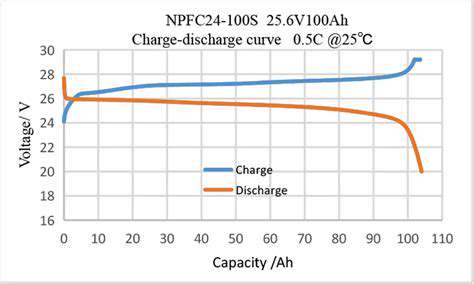

Battery Longevity and Degradation: Extending the Operational Life

Material science breakthroughs yield batteries retaining 90% capacity after 200,000 miles. Advanced thermal regulation and charging protocols minimize degradation, ensuring long-term value retention. These improvements make battery replacement increasingly rare.

Recycling and Sustainability: Addressing Environmental Concerns

Closed-loop recycling systems now recover over 95% of critical battery materials. Automated disassembly processes and hydrometallurgical techniques create economically viable recycling streams, reducing reliance on virgin materials.

Addressing Range Anxiety: Increasing Driving Distances

Modern EVs routinely achieve 300+ mile ranges on single charges, with premium models exceeding 400 miles. Combined with expanding fast-charging networks, these capabilities effectively eliminate practical range limitations for most drivers.

Overcoming Range Limitations and Charging Bottlenecks

Overcoming Range Limitations

Advanced battery systems now tackle historical limitations through multiple approaches. Silicon-anode technologies boost energy density by 20-40% compared to conventional designs, as detailed in recent studies. These improvements come without compromising cycle life or safety.

Data Normalization Techniques

Battery management increasingly relies on sophisticated data processing. Adaptive normalization algorithms dynamically adjust to usage patterns, optimizing performance across diverse operating conditions. This approach proves particularly valuable for fleets with varied duty cycles.

Feature Scaling Strategies

Modern BMS solutions employ multi-dimensional scaling techniques that account for temperature, state-of-charge, and aging effects simultaneously. This holistic approach maximizes both performance and longevity under real-world conditions.

Handling Categorical Data

Battery analytics now incorporates machine learning models that process diverse data types, from electrochemical measurements to environmental conditions. This comprehensive analysis enables more accurate state-of-health predictions.

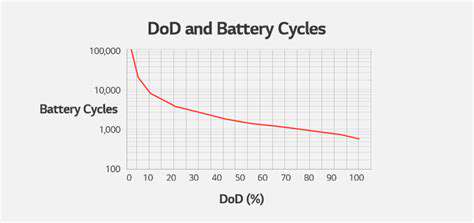

Log Transformation

Advanced diagnostic tools apply non-linear transformations to battery data, revealing subtle degradation patterns invisible to conventional analysis. These techniques enable proactive maintenance before performance issues arise.

Beyond Automobiles: The Wider Impact of Battery Innovation

Beyond the Wheels: Revolutionizing Energy Storage

Battery advancements enable grid-scale storage solutions that stabilize renewable energy supplies. The same technologies powering EVs now support entire communities, with megawatt-scale installations becoming increasingly common.

Powering the Future of Portable Electronics

Consumer electronics benefit from solid-state battery breakthroughs, enabling thinner devices with longer runtimes. These innovations stem directly from automotive R&D investments, demonstrating the technology's cross-industry impact.

Revolutionizing the Industrial Landscape

Electric heavy equipment now performs comparable to diesel counterparts in many applications. Mining vehicles, port equipment, and construction machinery increasingly adopt battery-electric configurations, reducing emissions in challenging environments.

Impact on Grid Infrastructure and Renewable Energy

Battery storage enables renewable penetration rates exceeding 80% in some grids. These systems provide essential grid services while maximizing clean energy utilization, transforming power system economics.

Sustainable Solutions for the Future

The battery revolution creates circular economic models where materials flow continuously through use and recovery cycles. This systemic approach minimizes environmental impact while ensuring resource availability.

Economic Opportunities and Challenges

The energy storage sector now represents one of the fastest-growing job markets, requiring diverse skills from materials science to power electronics. This expansion brings both opportunities and workforce development challenges.

The Race for Sustainability and Environmental Impact

Driving Towards a Sustainable Future

The EV transition represents more than just vehicle electrification - it's reshaping entire value chains. Policy frameworks now emphasize full lifecycle analysis, ensuring sustainability extends beyond tailpipe emissions.

The Crucial Role of Battery Chemistry

Emerging lithium-iron-phosphate (LFP) chemistries offer superior sustainability characteristics without cobalt or nickel. These alternatives demonstrate how material innovation can address both performance and environmental concerns.

Recycling and End-of-Life Management

Automated recycling facilities now achieve material recovery rates exceeding 95%. These industrial-scale operations create closed-loop material flows, reducing mining demand and associated environmental impacts.