Advances in Lithium Iron Phosphate (LFP) Batteries

Advanced Materials for Enhanced Performance

Advanced Polymer Composites for Enhanced Performance

Modern industries increasingly rely on polymer composites, materials that merge polymers with fibers or fillers to create something truly special. Picture a material that's simultaneously feather-light yet remarkably sturdy - that's the magic of these composites. From sleek car parts to soaring aircraft components, these materials shine where every gram counts and performance can't be compromised.

What makes them revolutionary? Their uncanny ability to slash weight while boosting strength leads to dramatic energy conservation across applications. Engineers particularly value how they can fine-tune these materials by adjusting their composition, crafting perfect solutions for specific challenges.

Lightweight and Durable Structures

Consider the aerospace sector, where shaving ounces translates directly to fuel savings. Polymer composites deliver this weight reduction without sacrificing durability - in fact, they often outlast traditional materials. This dual advantage means vehicles and aircraft enjoy both immediate performance gains and long-term cost benefits from reduced maintenance.

The numbers speak for themselves: these materials offer strength comparable to steel at a fraction of the weight, revolutionizing design possibilities. This breakthrough enables aircraft to carry more while maneuvering with greater agility, all while maintaining structural integrity over extended periods.

Enhanced Properties through Material Combinations

The true genius of these composites lies in their chameleon-like adaptability. Need better heat resistance? Add ceramic fillers. Require electrical conductivity? Incorporate metallic particles. This modular approach allows engineers to create custom material solutions that precisely match application requirements, opening doors to innovations previously deemed impossible.

Tailored Properties for Specific Applications

Take protective gear as an example. By embedding impact-absorbing particles within the polymer matrix, manufacturers create safety equipment that's both lightweight and extraordinarily tough. This level of customization extends across industries, enabling solutions as diverse as flexible electronics and ultra-strong construction materials.

Manufacturing and Processing Considerations

Crafting these advanced materials requires precision akin to baking the perfect soufflé. Temperature, pressure, and mixing ratios must be meticulously controlled to achieve desired properties. As applications grow more sophisticated, so too do the manufacturing techniques, with cutting-edge methods emerging to meet these evolving demands.

The production landscape is transforming rapidly, with new techniques achieving unprecedented control over material properties at microscopic levels. This progress ensures composites can meet even the most stringent performance requirements of tomorrow's technologies.

Cost-Effectiveness and Sustainability

While the initial price tag might raise eyebrows, the long-term economics tell a different story. Reduced maintenance needs and extended service life often make composites more economical over time. Environmentally conscious manufacturers particularly appreciate how these materials can incorporate recycled content and even bio-based components.

The green revolution in materials science is gaining momentum, with sustainable composites leading the charge toward eco-friendly industrial solutions. Forward-thinking companies recognize this dual advantage of performance and sustainability as a competitive edge in today's market.

Innovative Battery Cell Design for Increased Energy Density and Efficiency

Advanced Materials for Enhanced Performance

The battery revolution hinges on material breakthroughs. Lithium metal and silicon anodes represent game-changing technologies, potentially storing several times more energy than traditional graphite designs. While these materials present challenges like dendrite formation, researchers are making strides in stabilizing them through innovative composite approaches.

Emerging solutions incorporate nanomaterials like graphene to create conductive networks that enhance both safety and performance. These advanced composites enable batteries to charge faster while maintaining stability over hundreds of cycles.

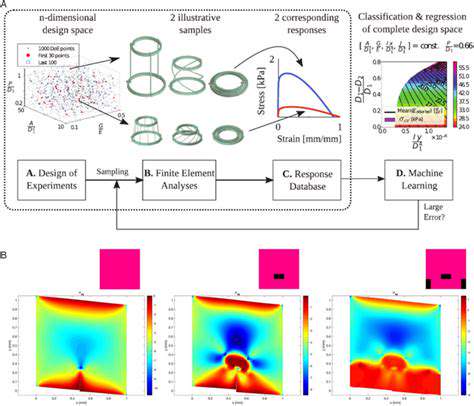

Optimized Electrode Architecture for Enhanced Conductivity

Modern electrode designs resemble microscopic cities, with carefully planned roads for ion traffic. By engineering porous, three-dimensional structures, scientists create electrode surfaces that could cover football fields if unfolded. This architectural approach dramatically increases reaction sites while reducing ion travel distances.

Nanoscale engineering takes this further, ensuring every particle of active material contributes effectively. The result? Batteries that charge in minutes rather than hours, without sacrificing capacity or lifespan.

Improved Electrolyte Design for Enhanced Safety and Stability

The liquid heart of batteries is undergoing its own revolution. Next-generation electrolytes combine innovative salts with advanced solvents to create formulations that resist degradation even under extreme conditions. Some even incorporate self-healing mechanisms that automatically repair minor damage during operation.

These advancements address one of consumers' greatest concerns: battery safety under real-world conditions. From preventing thermal runaway to enabling operation in arctic cold or desert heat, modern electrolytes expand what's possible with energy storage.

Enhanced Thermal Management for Improved Cycling Life

Managing battery temperature resembles maintaining a gourmet chocolate's perfect consistency - too hot or too cold ruins everything. Advanced systems now employ everything from microfluidic cooling channels to phase-change materials that absorb excess heat like microscopic sponges.

Some designs even incorporate smart systems that dynamically adjust cooling based on real-time temperature maps of the battery. This precision thermal control can double or triple a battery's usable life while maintaining consistent performance.

Advanced Manufacturing Techniques for Scalable Production

Turning lab breakthroughs into affordable products requires manufacturing innovation. New roll-to-roll processes and precision deposition techniques are bringing down costs while improving quality consistency. Automated optical inspection systems now catch defects early, ensuring only perfect cells reach consumers.

The holy grail? Factories that can retool overnight to produce next-generation designs without costly downtime. Flexible manufacturing approaches are making this vision increasingly realistic, accelerating the pace of battery innovation.

Safety Considerations and Robustness Testing

Before any battery powers your device, it survives a gauntlet worthy of a superhero origin story. Crush tests, nail penetration, extreme temperature cycles - these are just the beginning. Modern test protocols simulate years of use in weeks, identifying potential failure modes before they reach consumers.

Advanced monitoring systems now provide real-time health assessments, potentially warning of issues before they become problems. This multilayered safety approach builds the trust needed for widespread adoption of new battery technologies.

Read more about Advances in Lithium Iron Phosphate (LFP) Batteries

Hot Recommendations

- Offshore Wind for Industrial Power

- Agrivoltaics: Dual Land Use with Solar Energy Advancements: Sustainable Farming

- Hydrogen as an Energy Storage Medium: Production, Conversion, and Usage

- Utility Scale Battery Storage: Successful Project Case Studies

- The Role of Energy Storage in Grid Peak Shaving

- The Role of Startups in Renewable Energy

- The Role of Blockchain in Decentralization of Energy Generation

- The Future of Wind Energy Advancements in Design

- Synchronous Condensers and Grid Inertia in a Renewable Energy Grid

- Corporate Renewable Procurement for Government Agencies