Wind Energy Advancements for Green Hydrogen Production: Decarbonization

Harnessing the Power of the Wind

Wind energy, a renewable and sustainable source of power, is increasingly being recognized as a crucial component in the fight against climate change. Harnessing the consistent and often powerful winds across the globe presents a significant opportunity to generate clean electricity, reducing our reliance on fossil fuels. This potent energy source, capable of powering entire grids and industries, is a cornerstone of the transition towards a sustainable energy future.

The vast potential of wind power is driven by the natural movement of air masses. Converting this natural phenomenon into usable electricity is a process that has evolved significantly over the years, with modern wind turbines now capable of capturing a much larger percentage of the wind's energy.

Electrolysis: A Critical Stepping Stone

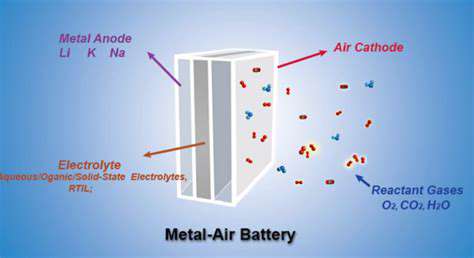

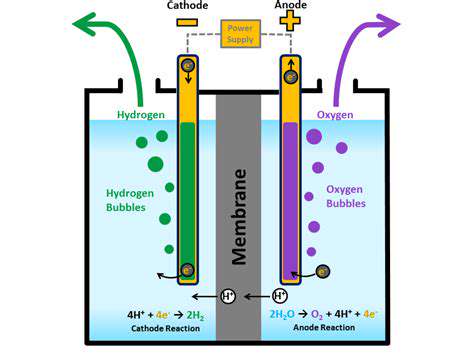

Electrolysis, a process that uses electricity to split water into hydrogen and oxygen, is a critical technology in the quest for clean energy. It offers a pathway to produce hydrogen, a versatile energy carrier that can be used in various applications, from transportation to industrial processes. Implementing electrolysis alongside wind power creates a closed-loop system, further optimizing the utilization of renewable energy sources.

Synergistic Benefits of Wind and Electrolysis

Combining wind power with electrolysis creates a powerful synergy. Wind turbines generate clean electricity, which is then used to drive the electrolysis process. This approach eliminates the need for fossil fuels in hydrogen production, resulting in a considerably lower carbon footprint compared to traditional methods. Furthermore, the excess energy generated by wind turbines can be stored as hydrogen, providing a valuable solution for intermittent energy sources.

The integration of these technologies allows for the creation of a more robust and resilient energy system. This is particularly important in areas with fluctuating wind speeds, as stored hydrogen can be used to balance the energy supply.

Challenges and Opportunities in Implementation

While the combination of wind power and electrolysis holds immense promise, several challenges must be addressed for widespread adoption. The cost-effectiveness of electrolysis technology needs improvement, and developing efficient storage solutions for hydrogen is another critical area of research. However, these challenges are not insurmountable, and significant advancements are being made in both areas.

Technological Advancements in Electrolysis

Ongoing research and development efforts are focusing on improving the efficiency and reducing the cost of electrolysis systems. New materials and technologies are being explored to increase the process's overall efficiency, reducing the amount of energy required to produce hydrogen. This progress is essential for making electrolysis a viable and cost-competitive alternative to traditional hydrogen production methods. The continuous innovation in materials science and electrochemical engineering promises significant improvements in the coming years.

The Future of Sustainable Energy Through Integration

The future of sustainable energy hinges on the successful integration of wind power and electrolysis. This synergy not only reduces reliance on fossil fuels but also opens doors to a wider range of applications for renewable energy. From powering vehicles to generating heat and electricity in various sectors, the potential of this combined approach is vast. Continued investment in research and development, along with supportive policies, will be critical for realizing the full potential of this clean energy solution.

The Electrolysis Process: Converting Wind Energy to Hydrogen

Electrolysis Fundamentals

Electrolysis, a crucial electrochemical process, involves using an electric current to drive a non-spontaneous chemical reaction. This process is fundamental in various industries, from refining metals to producing chemicals, and even in the realm of personal care. Understanding the underlying principles is key to harnessing its power effectively. The process relies on the application of an electric potential across a solution containing ions, forcing them to undergo oxidation or reduction at the electrodes. This controlled transformation allows for the isolation and purification of specific elements or compounds.

Several key factors influence the efficiency and effectiveness of electrolysis, including the choice of electrolyte, the type of electrodes, and the applied current. Different electrolytes will have varying degrees of ionic conductivity, impacting the rate at which the reaction proceeds. The material of the electrodes plays a vital role in determining the reactions that occur at each electrode, and the applied current affects the rate of electron transfer, influencing the overall reaction rate.

Applications of Electrolysis

Electrolysis finds extensive application in various sectors, including the production of metals like aluminum and copper, the purification of water, and the creation of various chemicals. The process is particularly important in the refining of metals, allowing for the extraction of pure metals from their ores. This process is often energy-intensive, but the high purity of the resultant metals makes it economically viable.

Another significant application is in the production of chlorine and sodium hydroxide through the electrolysis of brine. This process is critical in numerous industrial applications, from water treatment to the manufacturing of plastics and paper. The production of hydrogen gas, a vital component in numerous industrial processes and also a potential clean energy source, is also achieved using electrolysis.

Beyond industrial applications, electrolysis plays a role in various consumer products. Electroplating, a process used to coat metal objects with a layer of another metal, utilizes electrolysis to achieve a desired aesthetic or protective finish. This controlled process also allows for the removal of unwanted substances, such as rust and tarnish from metal surfaces.

Furthermore, electrolysis is becoming increasingly important in the realm of environmental remediation. Electrolysis can be used to treat contaminated water sources and remove pollutants, making it a valuable tool in environmental cleanup efforts. This innovative approach offers a promising solution for addressing environmental challenges.

Electrolysis' versatility extends to diverse applications, showcasing its importance across various industries.

Overcoming Challenges and Optimizing Efficiency

Overcoming Obstacles in Project Management

Effective project management hinges on proactively identifying and addressing potential roadblocks. Recognizing challenges early allows for the development of contingency plans and the allocation of resources to minimize their impact. This proactive approach is crucial for maintaining project timelines and budgets, ensuring that projects remain on track and deliver desired outcomes. A well-structured project management framework includes procedures for identifying and responding to potential obstacles, which often stem from unforeseen issues like resource constraints or changes in stakeholder priorities.

Importance of Adaptability in Project Environments

Project environments are inherently dynamic. Unexpected events, shifting priorities, and evolving technologies are common occurrences that can disrupt the project's flow. A successful project manager must exhibit flexibility and adaptability to navigate these challenges. This includes re-evaluating project plans, adjusting timelines, and reallocating resources as needed. Adaptability is key to maintaining momentum and ensuring that projects remain on track, even when faced with unforeseen obstacles.

Risk Assessment and Mitigation Strategies

Thorough risk assessment is essential for identifying potential threats to project success. This involves analyzing potential risks, evaluating their likelihood and potential impact, and developing mitigation strategies. Proactive risk management ensures that projects are prepared for potential disruptions and allows for the development of contingency plans. This process enables project teams to anticipate and address challenges before they escalate, minimizing the likelihood of project delays or failures.

Effective Communication and Collaboration

Transparent and consistent communication is paramount for successful project management. This includes keeping all stakeholders informed about project progress, challenges, and potential risks. Open communication fosters collaboration and ensures that everyone is aligned on project goals. Clear communication channels and regular project updates help to identify and resolve issues promptly, preventing them from escalating into major problems.

Optimizing Resource Allocation and Utilization

Efficient resource allocation is critical for project success. This involves identifying the necessary resources (personnel, materials, and finances) and ensuring they are available when and where needed. Effective resource management minimizes project delays and ensures that projects are completed within budget and on time. Project managers need to carefully evaluate resource needs and allocate them strategically to maximize productivity and minimize waste.

Time Management and Prioritization Techniques

Managing time effectively is essential for meeting project deadlines. This involves creating realistic schedules, prioritizing tasks, and allocating sufficient time for each project phase. Prioritization techniques help to focus efforts on the most critical tasks, ensuring that the project's objectives are met in a timely manner. Time management skills are crucial for project success, enabling project managers to stay organized and focused on achieving project goals.

Continuous Improvement and Learning

Project management is an iterative process that benefits from continuous improvement. Learning from past experiences and implementing best practices helps to optimize future projects. Analyzing project successes and failures, and identifying areas for improvement, is crucial for enhancing project management methodologies and ultimately improving project outcomes. Regularly evaluating project processes and adapting them based on feedback and lessons learned leads to more efficient and effective future projects.

The Future of Green Hydrogen and Wind Energy Integration

Green Hydrogen: A Promising Energy Source

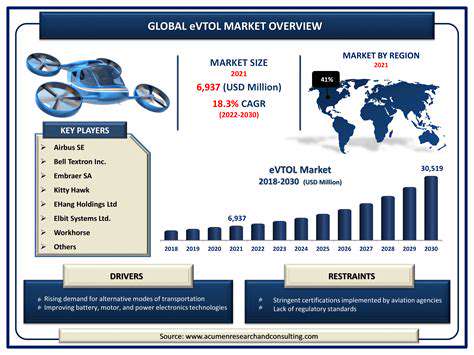

The global energy landscape is undergoing a significant transformation, with a growing emphasis on renewable and sustainable energy sources. Green hydrogen, produced through the electrolysis of water using renewable energy, is emerging as a promising contender in this transition. It offers a clean and potentially scalable alternative to fossil fuels for various applications, from transportation to industrial processes. The potential for widespread adoption is significant, and ongoing research and development are paving the way for its broader integration into the energy matrix.

Challenges in Scalable Production

Despite the significant potential, several challenges remain in scaling up green hydrogen production. One crucial hurdle is the cost-effectiveness of the production process, particularly the efficient and cost-effective electrolysis technology. Currently, the cost of producing green hydrogen is often higher than that of traditional hydrogen production methods. This high cost is a significant barrier to widespread adoption, but ongoing advancements in electrolysis technologies and renewable energy are working to improve the efficiency and reduce the price of green hydrogen.

Applications Across Industries

The applications for green hydrogen are diverse and span multiple sectors. In the transportation sector, green hydrogen can power fuel cells in vehicles, reducing reliance on fossil fuels and emissions. Industrial applications are also being explored, with the potential to decarbonize processes such as steel production and ammonia synthesis. The potential for green hydrogen to play a key role in decarbonizing various industries is substantial.

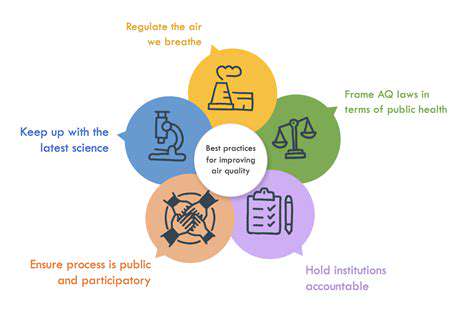

Infrastructure Development and Policy Support

The widespread adoption of green hydrogen requires significant investment in infrastructure. This includes pipelines and storage facilities, as well as hydrogen refueling stations and distribution networks. Governments and organizations must support the development and deployment of these infrastructure components to enable the efficient and effective use of green hydrogen. Policy support, including incentives and regulations, is crucial to accelerate the adoption of green hydrogen and encourage private sector investment. The development of clear and supportive policies is vital for market growth.

The Role of Renewable Energy Integration

The production of green hydrogen is intrinsically linked to the availability and reliability of renewable energy sources. Solar and wind power are key components in the electrolysis process. Ensuring a stable and consistent supply of renewable energy is essential for the long-term viability of green hydrogen production. Advancements in energy storage technologies are also crucial to mitigate the intermittency of renewable sources, allowing for a more reliable and sustainable green hydrogen supply chain.

Read more about Wind Energy Advancements for Green Hydrogen Production: Decarbonization

Hot Recommendations

- Solar Energy for Electric Vehicle Charging Stations

- Offshore Wind Repowering

- Agricultural Solar (Agrivoltaics): Synergies Between Food and Energy

- Airborne Wind Energy: Tapping High Altitude Winds

- Renewable Energy and Green Hydrogen: A Powerful Duo

- Geothermal Power Plant Technologies: Flash, Dry Steam, and Binary Cycle

- The Future of Offshore Wind Transmission

- The Role of Energy Storage in Enhancing Energy Security

- The Environmental Footprint of Modern Wind Energy Advancements: LCA Analysis

- Hydrogen Production with Energy Storage