Evaluating Potential Alternatives to Lithium ion Batteries

Flow Batteries: A Stable and Scalable Solution?

Advantages of Flow Batteries

Flow batteries, unlike traditional battery technologies, offer a unique combination of advantages, particularly regarding energy storage capacity and scalability. Their modular design allows for significant increases in energy storage simply by adding more tanks, a feature that is crucial for large-scale energy storage applications. This inherent scalability makes them a strong contender for grid-level energy storage, enabling the integration of intermittent renewable energy sources like solar and wind. Furthermore, flow batteries boast a longer lifespan compared to lithium-ion batteries, potentially reducing the need for frequent replacements and contributing to a more sustainable energy solution. The inherent safety of the electrolyte solutions used in flow batteries, compared to the flammable components in some lithium-ion batteries, is another significant benefit. This characteristic is essential in large-scale deployments, minimizing the risk of accidents and ensuring operational reliability.

Another key advantage is their ability to withstand many charge-discharge cycles. This resilience is critical for grid-scale applications where batteries undergo frequent charging and discharging. The stable electrochemical reactions within the battery system contribute to a consistent performance over time, unlike some battery chemistries that experience performance degradation after repeated cycles. This longevity and predictable performance profile are essential for reliable integration into existing power grids and contribute to the overall stability and reliability of the energy system.

Challenges and Considerations

Despite their compelling advantages, flow batteries are not without their challenges. One significant hurdle is the relatively high capital cost associated with the infrastructure needed to house the large electrolyte tanks. This initial investment can be a deterrent for widespread adoption, particularly in comparison to more established battery technologies. Moreover, the size and weight of the required tanks present logistical and infrastructure considerations, demanding specialized handling and storage solutions. This can be a significant factor in deployment scenarios, particularly for mobile or portable applications where space and weight are crucial.

Furthermore, the performance of flow batteries can be influenced by temperature fluctuations. Maintaining optimal operating temperatures to ensure consistent performance across different environments is crucial for reliable operation. The need for specialized temperature control systems adds to the complexity and cost of implementation, potentially impacting deployment in locations with extreme temperature variations. While research continues to address these challenges, they remain critical factors to consider in assessing the overall feasibility and economic viability of flow batteries for various applications.

The efficiency of energy conversion in flow batteries, while generally good, can still be an area for improvement compared to other technologies. Optimization of the electrochemical processes and electrolyte solutions are ongoing areas of research aimed at enhancing efficiency. Further research and development are crucial to address these challenges and unlock the full potential of flow batteries for a wider range of applications. This includes exploring innovative materials and designs to reduce costs, improve energy density, and enhance overall performance.

Metal-Air Batteries: Harvesting Energy from the Atmosphere

Metal-Air Batteries: A Promising Energy Source

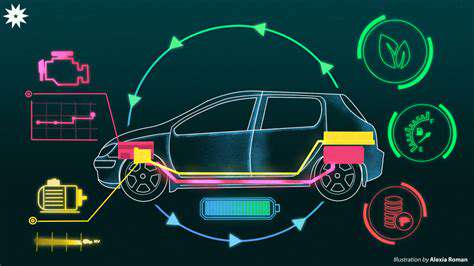

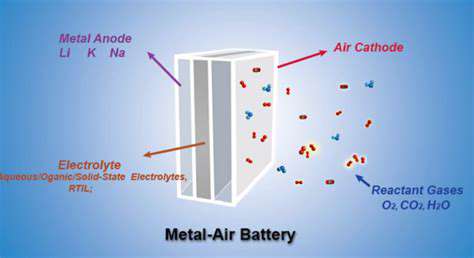

Metal-air batteries represent a promising avenue for energy storage, offering the potential for high energy density and reduced reliance on scarce lithium resources. These devices utilize a metal anode, often zinc or aluminum, and an oxygen cathode, drawing on the abundant and readily available atmospheric oxygen. This unique design dramatically increases the overall energy storage capacity compared to conventional lithium-ion batteries, making them a compelling alternative for various applications, from portable electronics to electric vehicles. Their high theoretical energy density is a key advantage, suggesting a significant leap in energy storage capabilities.

The fundamental electrochemical processes in metal-air batteries involve the oxidation of the metal anode and the reduction of oxygen at the cathode. This reaction generates electricity, and the overall reaction can be highly efficient. Significant research efforts focus on improving the catalytic activity of the oxygen reduction reaction, which is often the rate-limiting step in the process. This optimization is crucial for enhancing the performance and practical viability of metal-air batteries.

Challenges and Future Directions

Despite their potential, metal-air batteries face several challenges, including issues with the stability and durability of the metal anodes, which can degrade over multiple charge-discharge cycles. Also, the performance of the oxygen reduction reaction can be negatively impacted by various factors, such as the presence of impurities in the air and the operating conditions.

Future research efforts aim to address these challenges by employing novel materials and innovative designs for both the electrodes and the electrolytes. Developing more robust and stable anodes is critical for realizing the full potential of metal-air batteries, ensuring a long lifespan and reliability. Further advancements in catalyst materials and electrode architectures are expected to enhance the kinetics of the oxygen reduction reaction and minimize performance degradation over time. This will lead to improved battery performance and longevity.

Applications and Commercialization

The potential applications of metal-air batteries are quite extensive, ranging from consumer electronics to electric vehicles. Their high energy density and the use of abundant materials make them attractive alternatives to lithium-ion batteries, particularly in applications requiring high energy storage capacity. This potential for widespread adoption makes them an area of significant investment and development. The development of cost-effective manufacturing processes and scalable production methods is crucial for commercialization.

Furthermore, the focus on optimizing the battery's performance characteristics, such as cycle life and rate capability, is essential for making metal-air batteries a viable and attractive option for various consumer and industrial sectors. The pursuit of greater efficiency and durability will be a key driver in bringing these batteries to the market.

Read more about Evaluating Potential Alternatives to Lithium ion Batteries

Hot Recommendations

- Offshore Wind for Industrial Power

- Agrivoltaics: Dual Land Use with Solar Energy Advancements: Sustainable Farming

- Hydrogen as an Energy Storage Medium: Production, Conversion, and Usage

- Utility Scale Battery Storage: Successful Project Case Studies

- The Role of Energy Storage in Grid Peak Shaving

- The Role of Startups in Renewable Energy

- The Role of Blockchain in Decentralization of Energy Generation

- The Future of Wind Energy Advancements in Design

- Synchronous Condensers and Grid Inertia in a Renewable Energy Grid

- Corporate Renewable Procurement for Government Agencies