Advanced Materials for Enhanced Wind Turbine Blade Performance

Exploring the Potential of Bio-Based Materials

Bio-Based Polymers for Wind Turbine Blades

The utilization of bio-based polymers in wind turbine blades offers a remarkable solution for minimizing the ecological footprint of wind energy. These materials, sourced from renewable resources such as plant starch or cellulose, provide a sustainable replacement for conventional petroleum-based polymers. Their natural biodegradability and reduced carbon footprint make them an attractive option for environmentally conscious manufacturing practices in the wind energy industry. This strategy not only lessens environmental harm but also has the potential to decrease manufacturing expenses by leveraging easily accessible raw materials.

Further advancements in enhancing the mechanical characteristics of these bio-based polymers are essential. Enhancing their strength, rigidity, and resilience is vital to guarantee the structural stability of wind turbine blades, a key factor for their durability and safety in high-wind scenarios. This will also entail exploring innovative composite designs that merge bio-based polymers with other sustainable materials, possibly improving their overall efficacy.

Sustainable Composites for Wind Turbine Towers

Implementing sustainable composites in wind turbine towers presents a substantial opportunity to reduce environmental impact while maintaining structural robustness. These composites, frequently incorporating bio-based fibers or natural fillers, can substitute traditional concrete or steel structures, resulting in lower carbon emissions across manufacturing and transportation stages. The inherent strength and durability of these sustainable composites can lead to lighter tower designs, thereby reducing material requirements and the energy needed for transportation.

Improving the Durability of Bio-Based Coatings

Wind turbine components, continually exposed to severe weather conditions, necessitate robust coatings to prevent corrosion and degradation. Developing bio-based coatings that retain their protective qualities over the extended lifespan of a wind turbine is crucial for maximizing the economic feasibility of these renewable energy solutions. The resilience of these coatings must be tested under real-world conditions to evaluate their effectiveness in shielding the underlying materials from environmental factors. This research is pivotal for ensuring the long-term performance and sustainability of wind energy infrastructure.

Bio-Based Materials for Gearboxes and Other Components

Extending the application of bio-based materials beyond blades and towers to include critical components such as gearboxes and other mechanical parts is a significant stride towards a fully sustainable wind energy system. Bio-based materials with suitable mechanical properties can be incorporated into gearboxes, potentially enhancing their durability and reducing their ecological impact. This approach can lead to notable reductions in the carbon footprint of the entire wind turbine lifecycle, encompassing manufacturing, maintenance, and eventual disposal.

Investigating the compatibility and performance of bio-based materials with existing manufacturing processes is also crucial. This will facilitate the seamless integration of these innovative materials into current supply chains and manufacturing workflows, potentially accelerating their widespread adoption in the wind energy industry.

The Role of Bio-Based Materials in Recycling and Disposal

The environmental impact of wind turbine components extends beyond their manufacturing phase to include their eventual decommissioning and disposal. Optimizing the recyclability of bio-based materials is essential for a genuinely sustainable approach to wind energy. Developing efficient recycling processes for these materials ensures they do not contribute to landfill waste or environmental pollution. This recycling process also reduces reliance on virgin materials and further minimizes the overall environmental footprint.

Economic Viability and Scalability

The shift to bio-based materials in wind energy requires careful consideration of economic viability and production scalability. Evaluating the cost-effectiveness of bio-based materials relative to traditional counterparts is critical for widespread adoption. The scalability of production processes for bio-based materials must be assessed to ensure these materials can be produced on the scale needed to meet the demands of the expanding wind energy sector. This investigation must also consider the potential for cost reductions as production volume increases.

Smart Materials for Adaptive Blade Design

Smart Materials in Blade Design

Smart materials are transforming various industries, and the aerospace sector is no exception. Their unique ability to adapt to changing conditions makes them ideal for use in aircraft blades. These materials, often composites or alloys with embedded sensors and actuators, can react to environmental factors like temperature and stress, adjusting their properties accordingly. This adaptability ensures optimal performance and safety, as blades can dynamically respond to varying flight conditions.

The integration of smart materials into blade design promises significant improvements in efficiency and safety. This is especially crucial for high-performance aircraft, where even minor fluctuations in blade behavior can substantially impact overall flight characteristics. Researchers are exploring the use of smart materials to create blades that are more resilient to damage and more responsive to changing aerodynamic forces.

Adaptive Response to Changing Conditions

The core advantage of smart materials in blade design lies in their ability to adapt to changing flight conditions. For instance, in extreme weather situations, a blade equipped with smart materials could automatically adjust its shape to maintain structural integrity, preventing catastrophic failure. This responsiveness is critical for ensuring the safety of the aircraft and its passengers.

Smart materials can alter their stiffness or geometry in response to real-time feedback from embedded sensors. This dynamic response allows the blade to maintain optimal performance across a broad range of flight scenarios, from take-off and landing to cruising altitudes. This adaptive behavior reduces the need for complex and potentially heavy control systems.

Enhanced Durability and Longevity

Traditional blade materials often struggle to withstand the high stresses and temperatures encountered during flight. Smart materials, however, can adjust their internal structure to absorb or dissipate these forces, extending the blade's lifespan and reducing the need for frequent replacements. This translates to significant cost savings and reduced maintenance requirements for airlines.

By incorporating smart materials, blade durability can be significantly enhanced, resulting in a longer operational life for the aircraft. This reduced maintenance translates into substantial economic benefits for the aviation industry. The extended lifespan of blades also helps to minimize environmental impact by reducing material waste.

Potential Applications and Future Developments

The potential applications of smart materials in blade design are vast. Beyond improving durability and responsiveness, these materials can also be used to optimize blade shape for different flight conditions, leading to improved fuel efficiency and reduced noise pollution. Research into advanced materials and their integration into blade design is ongoing, promising even more innovative solutions in the future.

Future developments in smart materials technology could lead to blades that self-heal minor damage, further enhancing safety and reliability. This proactive approach to maintenance would represent a significant leap forward in aviation technology, paving the way for more efficient and sustainable aircraft.

Read more about Advanced Materials for Enhanced Wind Turbine Blade Performance

Hot Recommendations

- Offshore Wind for Industrial Power

- Agrivoltaics: Dual Land Use with Solar Energy Advancements: Sustainable Farming

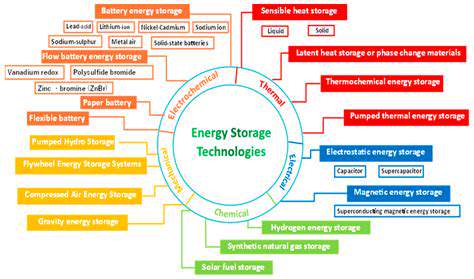

- Hydrogen as an Energy Storage Medium: Production, Conversion, and Usage

- Utility Scale Battery Storage: Successful Project Case Studies

- The Role of Energy Storage in Grid Peak Shaving

- The Role of Startups in Renewable Energy

- The Role of Blockchain in Decentralization of Energy Generation

- The Future of Wind Energy Advancements in Design

- Synchronous Condensers and Grid Inertia in a Renewable Energy Grid

- Corporate Renewable Procurement for Government Agencies