Comparing EV Waste Management Solutions

The Economic Considerations of EV Battery Recycling

Economic Incentives for EV Battery Recycling

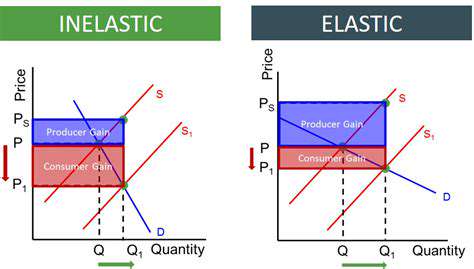

The economic viability of EV battery recycling is a crucial factor in the overall waste management strategy. Government incentives, tax credits, and subsidies for recycling facilities can significantly reduce the financial burden on businesses and encourage investment in this crucial infrastructure. These incentives are necessary to make recycling economically competitive with other disposal methods, creating a positive feedback loop for sustainability and driving innovation in the field. This fosters a circular economy, where raw materials are recovered and reused rather than being lost to landfills.

Furthermore, the potential for recovering valuable metals like lithium, cobalt, and nickel from batteries creates a strong economic incentive. The market value of these metals can provide a significant revenue stream for recycling facilities, making the process financially attractive and sustainable in the long term. This economic incentive is a key driver for the development and implementation of efficient and cost-effective recycling technologies.

Environmental Benefits and Cost Savings

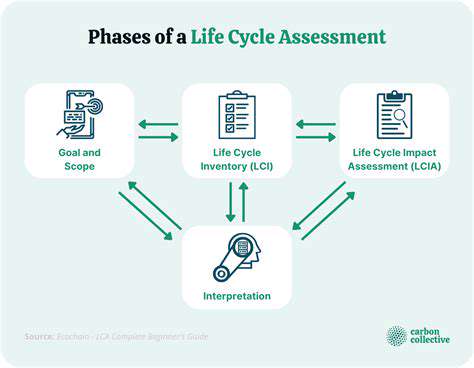

The environmental benefits of EV battery recycling are substantial, minimizing the environmental impact of lithium-ion batteries and promoting sustainable practices. Recycling reduces the need for mining new raw materials, lessening the ecological footprint associated with extracting these materials from the earth. This translates into significant cost savings in the long run, as it avoids the environmental damage and remediation costs associated with traditional mining practices.

By recovering valuable components from batteries, recycling also reduces the demand for virgin materials. This reduces the environmental burden associated with resource extraction, transportation, and processing, ultimately lowering the overall environmental cost of EV production and use.

Technological Advancements in Recycling Processes

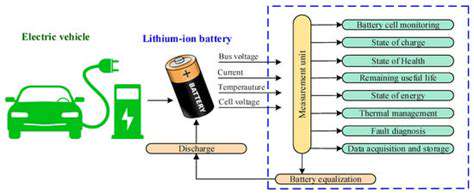

Continuous technological advancements in battery recycling are crucial for improving efficiency and cost-effectiveness. New technologies are constantly emerging, allowing for more effective separation and recovery of valuable materials. This includes innovations in chemical processing, mechanical separation, and hydrometallurgical techniques. These advancements can lead to significant cost reductions in the recycling process, making it more competitive with other disposal methods.

The development of advanced technologies for battery recycling is vital to the future success of the EV industry. These advancements can improve the quality of recycled materials, leading to higher metal recovery rates and a more sustainable supply chain.

The Role of Policy and Regulation

Government policies and regulations play a significant role in shaping the economics of EV battery recycling. Regulations regarding battery disposal and the handling of hazardous materials can influence the profitability of recycling facilities and the overall feasibility of recycling programs. Clear guidelines and standards promote responsible practices and ensure that recycling facilities operate in a safe and environmentally sound manner.

Policy frameworks that incentivize recycling and penalize improper disposal can drive significant changes in the market, encouraging a shift towards more sustainable practices in the EV industry.

Economic Considerations for Battery Material Recovery

The economic recovery of individual battery materials is a crucial component of the financial feasibility of EV battery recycling. The market price fluctuations of these materials, such as lithium, cobalt, and nickel, directly impact the profitability of recycling operations. Understanding these market dynamics and the potential for future price volatility is critical for long-term planning and investment in recycling infrastructure.

Analysis of Recycling Infrastructure Development

The development of robust and efficient recycling infrastructure is essential to support the growing EV market. This includes establishing recycling facilities, developing specialized equipment, and training the workforce to handle the complex procedures involved. Careful consideration of the location, capacity, and efficiency of these facilities is crucial for ensuring the economic viability of the recycling process. This includes evaluating the costs associated with building and operating these facilities and optimizing their location to minimize transportation costs and maximize material recovery.

The Impact of EV Battery Recycling on Global Supply Chains

The expansion of EV battery recycling has the potential to significantly impact global supply chains, particularly for raw materials used in the production of batteries. Recycling operations can create localized supply chains, reducing reliance on foreign imports and fostering economic growth in regions where these facilities are located. This localized sourcing can enhance the sustainability and resilience of the global EV industry by reducing transportation costs and mitigating geopolitical risks associated with material acquisition.

Read more about Comparing EV Waste Management Solutions

Hot Recommendations

- Offshore Wind for Industrial Power

- Agrivoltaics: Dual Land Use with Solar Energy Advancements: Sustainable Farming

- Hydrogen as an Energy Storage Medium: Production, Conversion, and Usage

- Utility Scale Battery Storage: Successful Project Case Studies

- The Role of Energy Storage in Grid Peak Shaving

- The Role of Startups in Renewable Energy

- The Role of Blockchain in Decentralization of Energy Generation

- The Future of Wind Energy Advancements in Design

- Synchronous Condensers and Grid Inertia in a Renewable Energy Grid

- Corporate Renewable Procurement for Government Agencies