Comparing Life Cycle Emissions of EVs and Hybrids

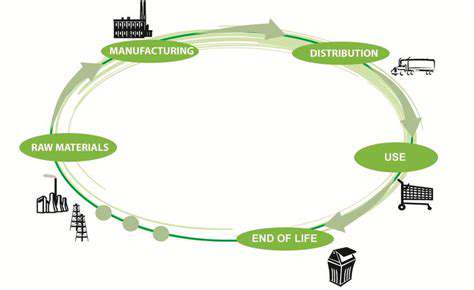

One of the most crucial steps in an LCA is the inventory analysis, where data is collected on the inputs and outputs of the product or process at each stage of its life cycle. This includes tracking material flows, energy consumption, and emissions releases. The accuracy and completeness of the data are paramount for obtaining reliable results.

Gathering data for each stage can be challenging, requiring access to a variety of sources such as industrial databases, engineering specifications, and scientific literature. Attention to detail and rigorous data validation are essential for ensuring the accuracy and reliability of the final assessment.

Impact Assessment: Evaluating the Consequence

Once the inventory data has been compiled, the impact assessment phase evaluates the environmental significance of the identified inputs and outputs. This involves using standardized methods to convert the inventory data into impact indicators, such as greenhouse gas emissions, water use, and waste generation.

Interpretation and Reporting: Communicating Results

The results of the LCA are then interpreted and presented in a comprehensive report. This involves analyzing the findings in relation to the defined goals and scope, identifying areas of high environmental impact, and formulating recommendations for improvement. Properly communicated results ensure transparency and facilitate informed decision-making.

Effective communication of LCA results is crucial for engaging stakeholders and driving change. Clear and concise reporting, supported by visualizations and summaries, facilitates understanding and enables the adoption of sustainable practices.

Life Cycle Thinking for Sustainable Solutions

LCA empowers us to move beyond a narrow focus on individual product stages and instead consider the entire life cycle of a product or process. This life cycle thinking is fundamental to developing more sustainable solutions. By evaluating the environmental impacts throughout the entire process, we can identify opportunities for reducing environmental burdens and creating more sustainable products and practices.

Ultimately, LCA promotes a holistic approach to sustainability, fostering innovation and progress towards a more environmentally friendly future.

Raw Material Extraction and Manufacturing: A Significant Factor

Raw Material Acquisition

The initial phase of any manufacturing process hinges on the secure and efficient acquisition of raw materials. This involves meticulous sourcing strategies, encompassing identifying reliable suppliers, negotiating favorable contracts, and ensuring consistent quality control measures throughout the procurement process. Effective raw material acquisition is paramount to maintaining production schedules and minimizing cost overruns.

Furthermore, geographical proximity of suppliers can significantly impact transportation costs and delivery times. A strategic sourcing approach considers these factors, ensuring that the overall cost of raw materials is optimized while maintaining the necessary production capacity.

Material Characterization and Testing

Before raw materials are processed, rigorous characterization and testing procedures are essential. This ensures that the materials meet the specific quality standards required by the manufacturing process. These tests often involve determining key properties such as chemical composition, physical attributes, and mechanical strength, validating that the materials align with the predetermined specifications.

Extraction Techniques

The extraction methods employed depend heavily on the type of raw material. For instance, mining techniques differ significantly for minerals compared to agricultural practices for crops. Understanding the intricacies of these extraction processes is crucial for maximizing yields and minimizing environmental impact.

Extraction procedures must adhere to stringent environmental regulations and safety standards. This is vital to prevent pollution and ensure the well-being of workers and surrounding communities.

Manufacturing Processes

Once the raw materials are acquired and characterized, the manufacturing process begins. This step involves transforming the raw materials into intermediate or finished products. The manufacturing process itself can vary widely depending on the specific product and its intended application. Different manufacturing processes can be used, such as molding, casting, machining, or assembly. All these processes are essential to achieving the desired product characteristics.

Quality Control and Assurance

Throughout the extraction and manufacturing process, rigorous quality control measures are implemented. These measures ensure that the final product meets the predefined quality standards and specifications. This process encompasses inspections at various stages of production and regular testing of intermediate and final products.

Implementing robust quality control systems not only maintains product quality but also ensures customer satisfaction and reduces the risk of product defects or recalls. Accurate quality control procedures are integral to maintaining a company's reputation and ensuring customer loyalty.

Environmental Considerations

The extraction and manufacturing of raw materials can have significant environmental impacts. Sustainability considerations are becoming increasingly important, as industries are under pressure to minimize their environmental footprint. These considerations include reducing waste, conserving resources, and employing environmentally friendly practices.

Minimizing the environmental impact of extraction and manufacturing is not just a responsible business practice, but also a crucial element for long-term viability in today's market. Sustainable practices often lead to cost savings in the long run and improve a company's reputation.

End-of-Life Considerations: Recycling and Disposal

End-of-Life Planning for Electronics

Properly managing end-of-life electronics is crucial for environmental sustainability and responsible resource management. Discarded electronics often contain hazardous materials that can leach into the environment, posing significant risks to both human health and ecosystems. Furthermore, the extraction of raw materials for new products often results in deforestation and habitat destruction, making responsible disposal a vital step in mitigating these impacts. Efficient recycling processes are essential to recover valuable components and prevent harmful waste from accumulating.

Effective end-of-life strategies involve a multifaceted approach that includes consumer awareness, producer responsibility, and robust recycling infrastructure. Consumers play a critical role by understanding the environmental impact of their electronics choices and opting for durable, repairable products whenever possible. Producers, on the other hand, must take responsibility for the entire lifecycle of their products, implementing environmentally sound designs and facilitating the collection and recycling of their products at the end of their useful lives.

Recycling Processes and Technologies

Advanced recycling technologies are constantly evolving, allowing for the extraction of valuable materials from electronic devices. These processes often involve mechanical separation, chemical treatments, and specialized procedures to recover precious metals like gold, silver, and copper. This process is essential to minimize the environmental footprint of electronic waste and to ensure a sustainable supply of these critical materials.

The recovery of valuable components from electronic waste is crucial for economic sustainability, reducing the need for primary resource extraction. This not only conserves natural resources but also supports the development of closed-loop systems that minimize waste and maximize the reuse of materials. Furthermore, these recycling processes contribute to the reduction of landfill waste, a significant environmental challenge. This is particularly important for the recovery of rare earth elements, which are becoming increasingly important in various technological applications.

Environmental and Social Impacts

The improper disposal of electronic waste can have devastating effects on the environment. Hazardous substances like lead, mercury, and cadmium, often present in electronic components, can contaminate soil and water sources, impacting human health and wildlife. Therefore, responsible and sustainable end-of-life management is crucial to mitigate these risks. This includes promoting the use of eco-friendly materials and implementing stringent regulations to prevent the release of harmful substances into the environment.

Beyond the environmental impact, the social implications of end-of-life electronics management are equally significant. Many recycling facilities are located in developing countries, where workers may face health risks from exposure to hazardous materials. Ensuring fair labor practices and safe working conditions is essential to mitigate these social impacts. Furthermore, the lack of proper recycling infrastructure in some regions contributes to the uncontrolled dumping of electronic waste, which further exacerbates environmental problems.