Comparing Servicing Requirements for EV Models

Introduction to Electric Vehicle Servicing

Understanding the Basics of EV Servicing

Electric vehicles (EVs) operate on a fundamentally different principle than traditional internal combustion engine (ICE) vehicles. This difference necessitates a unique approach to servicing. Understanding the key components, such as the battery management system (BMS), electric motors, and power electronics, is crucial for technicians to diagnose and repair EV issues effectively. This specialized knowledge differentiates EV servicing from traditional automotive maintenance, demanding a shift in skill sets and training for mechanics.

The battery pack in an EV is a complex system requiring careful handling and specialized tools. Proper charging procedures and battery health monitoring are critical to maintaining its lifespan and performance. Ignoring these nuances can lead to costly repairs and safety hazards. It's important to recognize that EV servicing often involves a deeper dive into electrical systems and software diagnostics than traditional car servicing.

Battery Management System (BMS) Considerations

The battery management system (BMS) is the brain of the EV battery pack. It monitors various parameters like cell voltage, temperature, and current flow to ensure optimal battery performance and safety. Diagnosing issues with the BMS requires specialized equipment and knowledge to identify problems such as cell imbalance, thermal runaway, or faulty communication protocols. This specialized diagnostic process is essential for preventing costly battery replacements and ensuring the long-term reliability of the EV.

Understanding the nuances of the BMS is paramount for effective EV servicing. Issues within the BMS can manifest in various ways, from charging anomalies to performance degradation. A thorough understanding of the BMS's role in regulating the entire system is vital for accurate diagnosis and efficient repairs. It also necessitates a grasp of the complex interplay between the BMS and other EV components.

Electrical System Diagnostics and Repair

EVs have intricate electrical systems that differ significantly from ICE vehicles. Diagnostics often involve sophisticated software tools and specialized equipment. Troubleshooting electrical faults in an EV requires a deep understanding of the complex interplay between the battery, motor, and power electronics. This involves using advanced diagnostic tools and protocols to pinpoint the exact source of the issue. Recognizing the role of software and control units in these systems is crucial to proper electrical system repair.

Specialized Tools and Training for EV Servicing

Effectively servicing EVs requires access to specialized tools and training. Standard automotive tools often aren't sufficient for tasks like battery pack inspections or BMS diagnostics. Specialized equipment and software for monitoring and analyzing electrical signals are vital. Furthermore, technicians need specialized training to understand the unique challenges and safety considerations involved in EV servicing. This training should cover topics such as battery safety, electrical system diagnostics, and the operation of EV-specific tools and software.

The increasing complexity of EV technology requires continuous professional development for technicians. Staying abreast of the latest advancements and industry best practices is crucial for ensuring high-quality servicing and preventing potential hazards. This ongoing learning and adaptation to the ever-evolving world of EV technology is essential for maintaining proficiency in this field.

Battery Health and Management Systems

Battery Health Monitoring

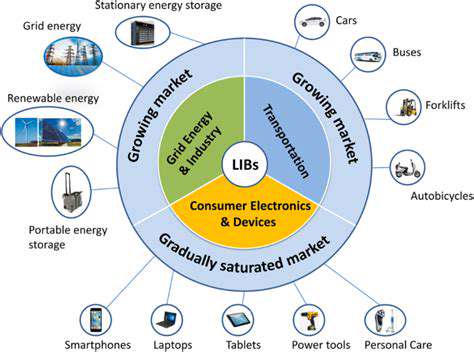

Battery health monitoring is a crucial aspect of any system incorporating rechargeable batteries. Accurate monitoring allows for proactive management of battery degradation and ensures optimal performance over the battery's lifespan. This involves tracking various parameters such as capacity, voltage, internal resistance, and temperature. Understanding these metrics allows for early detection of potential issues, preventing unexpected failures and extending the battery's useful life. Sophisticated algorithms and sensors are employed to continuously assess battery health, providing valuable insights into its current state and future performance.

The continuous monitoring of these parameters enables the system to identify patterns and anomalies. This data can be used to predict future performance and inform decisions related to battery replacement or maintenance schedules. Early intervention based on monitoring data can significantly reduce the risk of unexpected battery failures, minimizing downtime and repair costs.

Battery Management System (BMS) Functionality

A robust BMS is essential for maintaining the safety and performance of a battery system. Its primary function is to regulate the charging and discharging processes, ensuring that the battery operates within safe and optimal parameters. This includes controlling charging current, monitoring battery voltage and temperature, and preventing overcharging or over-discharging.

A well-designed BMS also provides critical safety features, such as short-circuit protection, thermal management, and cell balancing. These features are vital for preventing dangerous situations and protecting the battery pack from damage. The BMS safeguards the battery from potential hazards, ensuring longevity and reliability. Furthermore, it can optimize battery usage by adjusting charging and discharging rates based on real-time conditions, maximizing battery life.

Data logging and reporting capabilities are also key components of a modern BMS. The system collects and records critical data points, including charging and discharging profiles, temperature fluctuations, and overall system performance. This detailed historical data can be used for troubleshooting, performance analysis, and future system design improvements. The ability to analyze the collected data helps in identifying trends and optimizing battery usage for enhanced efficiency.

Strategies for Battery Longevity

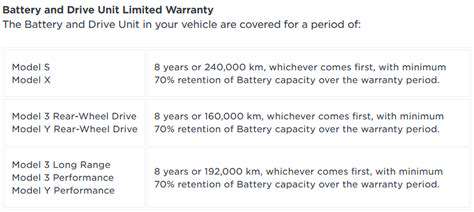

Implementing strategies for battery longevity involves careful consideration of various factors, including charging and discharging protocols, environmental conditions, and usage patterns. Optimizing charging profiles, for example, can significantly extend battery life by avoiding rapid charging and discharging cycles. Careful monitoring of battery temperature is also crucial, as extreme temperatures can negatively impact battery performance and lifespan.

Furthermore, understanding the specific usage patterns of the battery-powered device is critical. For example, if the device experiences periods of inactivity, implementing strategies to reduce self-discharge can extend battery life. Understanding the specific demands of the device and the environment in which it operates is essential for developing appropriate strategies for battery longevity. Proactive management of these factors will ensure the battery maintains optimal performance and longevity.

Charging System Maintenance

Preventive Maintenance Procedures

Regular maintenance is crucial for optimal charging system performance and longevity. This involves a series of checks and procedures designed to identify potential issues before they escalate into major problems. Regular inspections of all electrical connections are essential to prevent overheating and short circuits. This includes visually inspecting for corrosion, loose connections, or any signs of damage. Cleaning the charging system components, such as the battery terminals and contacts, with a specialized cleaner can greatly improve conductivity and overall efficiency. Furthermore, monitoring the charging system's operational parameters, such as voltage and current, using appropriate diagnostic tools is vital for identifying any anomalies early on. This proactive approach can save significant costs and downtime associated with unexpected breakdowns.

Maintaining accurate records of all maintenance activities, including dates, tasks performed, and any observations, is highly recommended. This detailed documentation serves as a valuable reference for future troubleshooting and provides a clear history of the charging system's operational status. Proper documentation allows for a comprehensive understanding of the system's performance trends over time. A well-maintained log can help predict potential problems and allow for timely interventions, ensuring consistent and reliable performance. Regular maintenance also helps to maintain the warranty on the charging system, as well as ensuring the safety of the equipment and personnel.

Troubleshooting Common Issues

Troubleshooting charging system problems can involve various techniques, from simple checks to more complex diagnostics. A key initial step is to check the battery's condition and charging status. A low battery charge or a damaged battery can significantly impact the charging system's performance. Inspecting the battery terminals for corrosion and ensuring proper connections is a fundamental part of troubleshooting. Checking the charging circuit for any obvious signs of damage, such as frayed wires or loose connections, is equally important.

If the charging system is still malfunctioning after these checks, further diagnostics may be required. This might involve using specialized equipment to measure voltage, current, and resistance within the charging circuit. A qualified technician can identify any discrepancies or faults in the system's operation. This process involves careful analysis and comparison of the measured values against expected parameters. Understanding the specific error codes provided by the charging system's diagnostic tools is essential to pinpoint the source of the issue. This will help in determining the appropriate corrective measures and avoiding unnecessary repairs.

In some cases, the problem might lie outside the charging system itself, such as in the electrical wiring or other components connected to it. A thorough inspection of the entire electrical system, including the power supply and the connected loads, is essential to ensure a complete diagnosis. A systematic approach, coupled with meticulous documentation, will greatly improve the efficiency and effectiveness of troubleshooting procedures.

Read more about Comparing Servicing Requirements for EV Models

Hot Recommendations

- Utility Scale Battery Storage: Successful Project Case Studies

- The Role of Energy Storage in Grid Peak Shaving

- The Role of Startups in Renewable Energy

- The Role of Blockchain in Decentralization of Energy Generation

- The Future of Wind Energy Advancements in Design

- Synchronous Condensers and Grid Inertia in a Renewable Energy Grid

- Corporate Renewable Procurement for Government Agencies

- The Global Push for Long Duration Energy Storage

- Renewable Energy and Job Creation: A Growing Sector

- Energy Storage in Commercial and Industrial Applications