Designing a Robotic Enabled Warehouse: Best Practices for Layout and Flow

Integrating Robots with Human Workers

Collaborative Robots: A New Era of Human-Robot Interaction

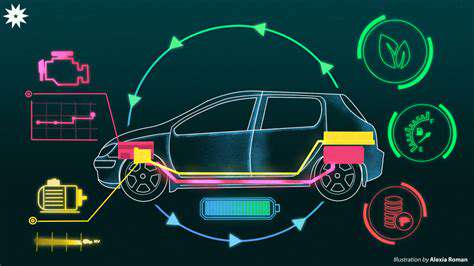

Integrating robots into the human workplace is no longer a futuristic concept but a rapidly evolving reality. Collaborative robots, or cobots, are designed specifically to work alongside humans, sharing tasks and enhancing efficiency. This new paradigm shifts the traditional view of robots as isolated machines to partners in the workplace, fostering a more dynamic and productive environment.

Enhanced Productivity and Efficiency

The integration of robots into workflows can significantly enhance productivity. Cobots excel at repetitive tasks, freeing up human workers to focus on more complex and creative endeavors. This division of labor leads to a more efficient use of resources and an overall increase in output.

Improved Safety and Reduced Risk

One of the most significant benefits of integrating robots is the potential for improved safety. Cobots are programmed to operate in close proximity to humans, yet their movements are carefully controlled and monitored to prevent accidents. This reduced risk of workplace injuries is a major advantage in various industries, especially those involving hazardous tasks.

Adaptability and Flexibility in the Workplace

The flexibility of cobots is a key factor in their growing adoption. Their programming can be adapted to different tasks and environments, making them invaluable assets in workplaces with fluctuating demands. This adaptability allows businesses to quickly adjust to changing needs and optimize their operations.

Adapting to Changing Workforce Demographics

The changing demographics of the workforce, including an aging population and a growing need for skilled labor, present new challenges and opportunities. Robotic integration can help bridge the gap in specific skill sets, allowing companies to maintain operations while also training their workforce for a more technological future. This is a crucial element for long-term viability.

Addressing Skill Gaps and Labor Shortages

In many industries, there are significant skill gaps and labor shortages. Integrating robots can address these issues by automating tasks that require specific skills, allowing human workers to focus on areas where their expertise is needed. This can lead to a more sustainable workforce and improved overall performance.

The Future of Human-Robot Collaboration

The future of human-robot collaboration is bright, with continued advancements in robotics and AI driving even more sophisticated integrations. The potential for further innovation in this area is immense, promising a future where humans and robots work seamlessly together, unlocking new levels of productivity and efficiency in various sectors. This collaborative approach will shape the future of work, offering a more comprehensive and adaptable workforce for the coming years.

Future-Proofing Your Warehouse Design

Optimizing for Automation

Integrating automation technologies, such as robotic process automation (RPA) and automated guided vehicles (AGVs), is crucial for future-proofing your warehouse. These technologies can significantly streamline operations, improve efficiency, and reduce labor costs. By automating repetitive tasks, you free up your human workforce to focus on higher-level strategic initiatives. Automation can also improve order fulfillment accuracy and speed, leading to greater customer satisfaction.

Implementing these systems requires careful planning and a thorough assessment of your current warehouse layout and processes. Consider the potential impact on your existing workflows and employee roles. Proper training and adaptation programs are essential for ensuring a smooth transition and maximizing the benefits of automation.

Embracing Data-Driven Decisions

Leveraging data analytics is key to understanding warehouse performance and identifying areas for improvement. Real-time data on inventory levels, order processing times, and resource utilization can provide valuable insights into optimizing your warehouse operations. These data-driven insights can help you predict potential bottlenecks, adjust staffing levels, and implement proactive solutions.

Employing robust warehouse management systems (WMS) is essential for collecting and analyzing this data. Choose a WMS that integrates seamlessly with your existing systems and provides comprehensive reporting capabilities. Using data-driven insights, you can also identify areas for improvement in your current processes.

Improving Inventory Management

Implementing sophisticated inventory management strategies is vital for a future-proof warehouse. Employing techniques like just-in-time inventory (JIT) can minimize storage space requirements and reduce holding costs. Employing advanced forecasting models, leveraging historical data, and considering future demand trends are crucial for optimal inventory levels.

Utilizing advanced inventory tracking systems is essential for ensuring accurate and real-time visibility into your stock levels. This enables proactive adjustments to inventory levels based on demand fluctuations, preventing stockouts and overstocking. This also helps you to streamline the entire process, from receiving to shipping.

Adapting to Evolving Customer Expectations

The ever-changing demands of customers require warehouses to adapt and evolve. Understanding and anticipating customer preferences, such as faster delivery times and personalized services, is critical for maintaining a competitive edge. Investing in technologies that facilitate omnichannel fulfillment and support personalized order management is essential for meeting these expectations.

Focus on providing exceptional customer service. This includes ensuring timely order fulfillment, providing detailed tracking information, and responding promptly to customer inquiries. This will ultimately translate to increased customer loyalty and positive reviews.

Securing and Enhancing Workforce Skills

Investing in the training and development of your workforce is essential for a future-proof warehouse. Staying abreast of evolving warehouse technologies and industry best practices is important for your team. Upskilling your employees in areas like data analytics, automation operation, and inventory management will enhance their capabilities and increase their value to the organization.

A well-trained and skilled workforce is critical for success in a rapidly changing warehouse environment. Promoting a culture of continuous learning and encouraging employees to embrace new technologies is paramount for remaining competitive. This will help to ensure that your warehouse is prepared for future challenges and opportunities.

Read more about Designing a Robotic Enabled Warehouse: Best Practices for Layout and Flow

Hot Recommendations

- Offshore Wind for Industrial Power

- Agrivoltaics: Dual Land Use with Solar Energy Advancements: Sustainable Farming

- Hydrogen as an Energy Storage Medium: Production, Conversion, and Usage

- Utility Scale Battery Storage: Successful Project Case Studies

- The Role of Energy Storage in Grid Peak Shaving

- The Role of Startups in Renewable Energy

- The Role of Blockchain in Decentralization of Energy Generation

- The Future of Wind Energy Advancements in Design

- Synchronous Condensers and Grid Inertia in a Renewable Energy Grid

- Corporate Renewable Procurement for Government Agencies