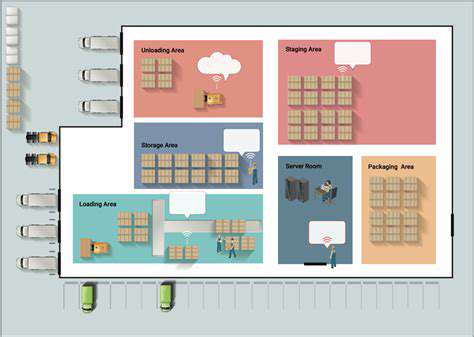

Real Time Location Systems (RTLS) for Warehouse Visibility

Applications of RTLS

The applications of RTLS are diverse and span various sectors. In healthcare, RTLS can be used to track medical equipment, patients, and staff. In warehousing and logistics, it can optimize inventory management and improve delivery times. Furthermore, retail stores can use RTLS to track inventory and customer flow, leading to better product placement and customer service.

Benefits of Implementing RTLS

Implementing an RTLS offers several benefits, including improved operational efficiency, reduced costs, and enhanced safety. Real-time location data allows for quicker response times to emergencies and enables better resource allocation. Furthermore, it can significantly reduce the time spent searching for misplaced items or personnel, ultimately leading to a more productive workflow.

Technological Advancements in RTLS

RTLS technology is constantly evolving, with new advancements improving accuracy, range, and cost-effectiveness. The integration of cloud-based solutions and advanced analytics has made RTLS more accessible and powerful. This means that users can access real-time location data from anywhere with an internet connection.

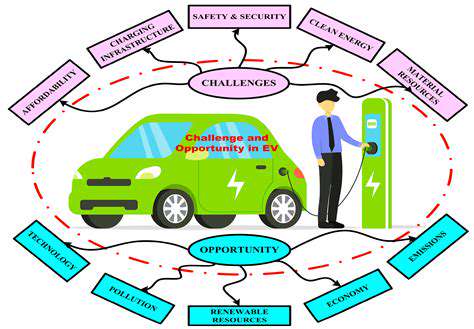

Challenges and Considerations

While RTLS offers numerous advantages, there are some challenges to consider. Cost can be a factor, especially for large-scale deployments. Ensuring the accuracy and reliability of the system is also crucial. Data privacy and security need to be addressed to maintain the confidentiality of the tracked information. Choosing the right technology and implementing a robust system is essential for success. Careful planning and consideration of potential issues are vital for a successful deployment.

Key Benefits of RTLS for Warehouse Visibility

Improved Inventory Accuracy

Real-time location systems (RTLS) significantly improve inventory accuracy in warehouses by providing precise location data for every item. This eliminates the guesswork associated with manual stocktaking and physical counts, leading to a much clearer picture of what's actually on hand. Accurate inventory tracking is crucial for efficient order fulfillment and reduces the risk of stockouts or overstocking, saving valuable time and resources.

By pinpointing the exact location of every item, RTLS minimizes the potential for errors in inventory management systems. This enhanced visibility allows for quicker identification of discrepancies, enabling prompt corrective actions to maintain accurate records.

Enhanced Order Fulfillment Efficiency

RTLS significantly streamlines order fulfillment processes, enabling warehouse staff to locate items much faster. This increased efficiency translates to quicker order picking and packing times, ultimately leading to faster order delivery and improved customer satisfaction. By having real-time visibility of inventory, warehouse staff can make data-driven decisions regarding optimal picking routes and warehouse layout.

The ability to track the movement of goods from storage to shipping directly impacts the overall productivity of the warehouse. This real-time visibility enables the optimization of workflows and the reduction of wasted time spent searching for items, leading to more efficient and profitable operations.

Reduced Operational Costs

Implementing an RTLS system in a warehouse can lead to substantial cost reductions over time. By minimizing errors in inventory management, the system reduces the need for costly rework and corrections. The automated tracking features of RTLS can significantly minimize labor costs associated with manual inventory counting and reduce the frequency of lost or misplaced goods.

Furthermore, improved efficiency in order fulfillment translates to fewer delays and quicker delivery times, contributing to reduced shipping costs and improved customer satisfaction, which ultimately boosts profitability.

Improved Safety and Security

Real-Time Location Systems enhance safety and security within a warehouse environment. Knowing the precise location of personnel and equipment in real time allows for better coordination and communication, reducing the risk of accidents and injuries. The tracking capabilities can provide valuable insights into activity patterns, helping identify potential hazards and improving safety protocols.

Moreover, RTLS can contribute to increased security by providing real-time tracking of valuable inventory and equipment, deterring theft and unauthorized access. This enhanced security measure safeguards the warehouse's assets and prevents costly losses.

Optimizing Inventory Management with RTLS

Understanding Inventory Costs

Accurate inventory management hinges on a deep understanding of the various costs associated with holding stock. These costs extend beyond the initial purchase price, encompassing storage expenses, insurance premiums, potential obsolescence risks, and the opportunity cost of tied-up capital. Understanding these costs is crucial for making informed decisions about ordering quantities and optimal storage strategies. This comprehensive understanding allows businesses to allocate resources effectively and maximize profitability.

Calculating the total cost of inventory involves meticulously tracking and analyzing each component. This includes detailed records of storage space, insurance premiums, potential losses due to damage or spoilage, and the financial implications of holding inventory that may become outdated or obsolete. By meticulously examining each factor, businesses can develop a more comprehensive view of their inventory costs and adjust their strategies accordingly.

Demand Forecasting and Planning

Effective inventory management relies heavily on accurate demand forecasting. Predicting future customer demand allows businesses to strategically manage their stock levels, minimizing the risk of stockouts or overstocking. This critical element of inventory optimization involves analyzing historical sales data, market trends, and external factors that might influence demand. Sophisticated forecasting models often employ statistical methods or machine learning algorithms for greater accuracy.

Planning for seasonal fluctuations and unexpected spikes in demand is essential for maintaining optimal inventory levels. Understanding anticipated variations in customer demand allows businesses to adjust their inventory strategies proactively, reducing the risk of disruptions in supply or excessive stockpiles.

Inventory Tracking and Control

Implementing a robust system for tracking inventory is paramount for successful inventory management. This encompasses using various technologies, such as barcode scanners, RFID tags, or inventory management software, to monitor stock levels in real-time. Real-time visibility into inventory levels allows businesses to make timely decisions regarding replenishment and prevent potential stockouts. Efficient tracking minimizes the risk of errors and discrepancies, ensuring accurate records of inventory movements.

Implementing strict controls over inventory movements is crucial to maintaining accuracy. This involves meticulous record-keeping of every transaction, from receiving goods to shipping orders. Maintaining a clear and detailed audit trail is vital for identifying and resolving discrepancies promptly.

Optimizing Ordering Processes

Streamlining the ordering process is essential for efficient inventory management. This involves establishing clear procedures for placing orders, receiving shipments, and updating inventory records. Optimized ordering processes reduce lead times and ensure that orders are processed accurately and swiftly. Using automated systems for order processing and inventory tracking improves efficiency and reduces the risk of errors.

Negotiating favorable terms with suppliers is another critical aspect of optimizing the ordering process. This includes exploring bulk discounts, extended payment terms, and other incentives that can lower the overall cost of inventory. By strategically negotiating with suppliers, businesses can further optimize their procurement strategies.

Implementing Inventory Management Software

Utilizing inventory management software is a crucial step in optimizing inventory processes. These systems offer a centralized platform for tracking inventory levels, managing orders, and generating reports. Effective inventory management software automates many manual tasks, freeing up personnel to focus on more strategic initiatives. This software often includes features for forecasting demand, optimizing order quantities, and tracking inventory movements in real-time.

Choosing the right software is essential for success. The software should be scalable, adaptable to the specific needs of the business, and user-friendly for staff. Careful consideration of the software's features and capabilities is critical before implementing it.

Maintaining Safety Stock Levels

Establishing appropriate safety stock levels is vital to mitigate the risk of stockouts. This involves considering factors such as lead times for replenishment, variability in demand, and potential disruptions to the supply chain. Calculating safety stock levels requires careful analysis of historical data and potential uncertainties. Maintaining sufficient safety stock minimizes the risk of customer dissatisfaction and lost sales.

Regularly reviewing and adjusting safety stock levels is crucial. As market conditions and demand patterns change, the optimal safety stock levels may also need to be adjusted. Businesses should regularly assess their safety stock levels to ensure they are aligned with current operational needs.

Enhanced Safety and Security with RTLS

Improving Warehouse Efficiency with Real-Time Tracking

Real-Time Location Systems (RTLS) are revolutionizing warehouse operations by providing precise and up-to-the-minute tracking of assets, personnel, and even goods in transit. This real-time visibility significantly enhances operational efficiency by enabling warehouse managers to optimize workflows, reduce errors, and minimize delays. By knowing the exact location of inventory and equipment at any given moment, warehouse staff can quickly locate items, improving order fulfillment times and reducing the risk of misplaced or damaged goods. This precise tracking also facilitates better inventory management, allowing for proactive adjustments to stock levels and preventing potential shortages or overstocking.

The ability to track the location of employees and key equipment in real-time also has significant benefits for safety and security. Knowing the precise whereabouts of personnel can improve response times in emergency situations. For example, in case of an accident or incident, knowing the location of personnel allows for immediate assistance and a faster response time. This enhanced situational awareness can significantly reduce risks and contribute to a safer working environment for everyone in the warehouse.

Enhanced Security Measures Through RTLS

Beyond operational efficiency, RTLS systems contribute significantly to warehouse security. By tracking assets like valuable equipment and materials, RTLS systems can deter theft and vandalism. The constant monitoring of assets' location enables the rapid identification of unauthorized access or movement, triggering alarms and allowing for swift intervention. Real-time tracking also helps in preventing pilferage and ensuring accountability for inventory movements. This constant vigilance and monitoring contribute to a more secure warehouse environment, protecting valuable assets and safeguarding against potential losses.

Implementing an RTLS system can also help improve security measures by tracking the movement of personnel within the warehouse. Knowing the location of employees can be crucial in maintaining a secure environment, particularly during off-peak hours or in areas with restricted access. This enhanced visibility can help prevent unauthorized individuals from entering restricted zones and contribute to a more secure and controlled environment, reducing the chances of security breaches.

Optimizing Inventory Management with RTLS

Real-time location systems play a crucial role in streamlining inventory management processes. RTLS provides a precise picture of inventory locations, enabling efficient stock control and minimizing inaccuracies. This real-time visibility allows for accurate inventory counts, leading to improved forecasting and reduced stock discrepancies. Warehouse managers can proactively monitor inventory levels and adjust order quantities accordingly, ensuring that the correct amount of stock is available when needed. This minimizes the risk of running out of essential items or overstocking, optimizing storage space and minimizing waste. The ability to locate inventory with precision significantly improves order fulfillment times, reducing delays and enhancing customer satisfaction.

The ability to track the location of goods throughout the warehouse, from receiving to shipping, enables better control over the entire supply chain. This enhanced visibility allows warehouse managers to identify bottlenecks and inefficiencies, enabling proactive measures to improve overall operational efficiency. This data can be used to optimize picking and packing routines, helping to ensure that orders are processed quickly and accurately. The comprehensive data gathered from RTLS systems can be used to make data-driven decisions regarding inventory management and warehouse layout. This helps to optimize warehouse space utilization and to ensure that inventory is stored and managed in the most efficient manner possible.

Real-Time Data Analysis for Warehouse Improvement

RTLS systems generate a wealth of real-time data about warehouse operations. This data can be analyzed to identify trends, bottlenecks, and areas for improvement. By analyzing the movement patterns of inventory, equipment, and personnel, warehouse managers can identify inefficiencies in workflows and optimize processes. This data-driven approach allows for informed decision-making, leading to significant improvements in warehouse productivity and efficiency. For instance, tracking the time taken for each step in the picking process can pinpoint areas where improvements can be made, ultimately reducing order fulfillment times. This data analysis can also help in identifying and addressing safety concerns within the warehouse environment.

The detailed insights provided by RTLS data analysis can also help in understanding and improving the layout of the warehouse. Identifying areas with high traffic or bottlenecks allows for adjustments to the layout for improved flow and efficiency. Optimizing warehouse space utilization and creating more efficient workflows is critical for cost savings and improved productivity. Real-time data analysis empowers warehouse managers to make data-driven decisions, leading to significant improvements in all areas of warehouse operations, including safety, security, and profitability.