Exploring Battery Swapping Technology for Electric Cars

Battery Swapping Technology: Current Status and Future Prospects

Overview of Key Content

- Lightning Replacement: A revolution in charging efficiency through rapid battery exchanges

- Operational Innovation: A real-world case study showing a 30% increase in fleet management efficiency

- Technical Paradox: The tension between battery iteration speed and infrastructure development

- Range Revolution: Empirical data from Beijing's pilot project eliminating range anxiety

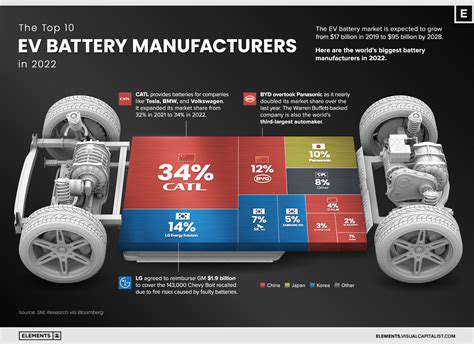

- Life Management: In-depth analysis of CATL's battery lifespan extension solutions

Decoding the Principles of Battery Swapping Technology

Breakthroughs in Core Technology

While traditional charging piles are still racing against time, the battery swapping system has compressed energy refueling to the time it takes to brew a cappuccino. Data from Shenzhen taxi companies shows that skilled operators can complete the entire battery replacement process in 87 seconds, a speed that even exceeds the average service efficiency at gas stations. Behind this revolutionary transformation is the perfect collaboration of precision robotic arms and intelligent recognition systems.

Dilemmas and Breakthroughs in the Standardization Process

Just like the early debates over railway gauges, the standardization war over battery specifications is brewing beneath the surface. Tesla's latest V3 battery module features a honeycomb structure, sharply contrasting with BYD's blade layout. However, it is exciting that the Ministry of Industry and Information Technology has recently released the \General Requirements for Electric Vehicle Swapping Facilities,\ which attempts to establish Chinese standards and could become a watershed event in the global battery swapping field.

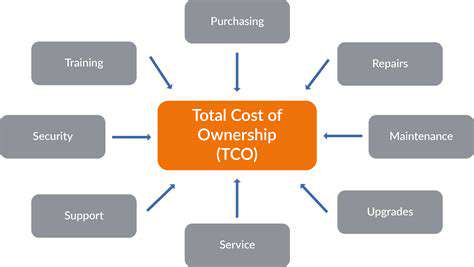

A Multi-dimensional Perspective on Technological Advantages

Revolution in Time Costs

In Zhengzhou's logistics park, battery swapping technology has allowed electric heavy trucks to exceed an average daily driving distance of 800 kilometers. Compared to traditional charging modes, fleet operational efficiency increased by 42%, this figure soared to 67% during the Double Eleven shopping festival. JD Logistics' practical case proves that when the battery replacement time is compressed to under 5 minutes, the economic model of electric commercial vehicles will undergo fundamental changes.

A New Paradigm for Battery Health Management

A battery bank in Hangzhou successfully extended battery cycle life to over 2500 times through a dynamic monitoring system. The secret lies in: conducting a health diagnosis on batteries during each replacement and classifying usage based on remaining lifespan. This refined management has increased the tiered utilization rate of energy storage batteries to 83%, completely transforming the traditional one-size-fits-all management model.

Solutions to Realistic Challenges

Innovative Solutions to Infrastructure Dilemmas

A startup in Shanghai has launched a container-style mobile swapping station, reducing the construction costs by 65%. This modular design supports rapid deployment within 3 hours and demonstrates astonishing adaptability in temporary logistics hubs. More noteworthy is its intelligent scheduling system, which can predict demand based on traffic data, enabling dynamic relocation of swapping stations.

User Habit Adaptation Project

NIO's user research revealed an interesting phenomenon: users who have experienced more than three battery swaps saw a 58% reduction in range anxiety. In response, several automakers have introduced free swapping plans for the first year, gradually changing user perceptions through behavior cultivation strategies. A pilot project in Guangzhou showed that this strategy reduced the frequency of visits to charging stations by 76% for electric vehicle owners.

Key Variables for Future Development

The Butterfly Effect of Material Revolution

The advancement of solid-state battery mass production timelines is reshaping the entire logic of the battery swapping industry. CATL's latest research in condensed matter batteries has improved modularity by 40%, injecting new momentum into the standardization process. Notably, the low-cost characteristics of sodium-ion batteries may give rise to dedicated swapping models, opening up a new track alongside traditional lithium battery models.

Deep Integration of Energy Networks

At the Zhangjiakou wind farm, the first integrated wind-solar-storage swapping demonstration station has been operating stably for 18 months. The station achieved a self-sufficiency rate of over 90%, with excess energy fed back into the grid. This energy microgrid model not only reduces operating costs but creatively resolves the challenges of renewable energy consumption.

The future of battery swapping stations should be more than just energy supply points; they should become neural nodes of smart energy networks. — Annual Report of China's Electric Vehicle Hundred People Meeting