Exploring Cost Differences in EV Repairs vs. ICE Vehicles

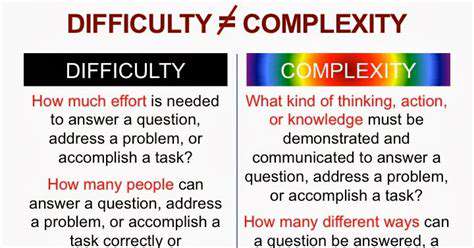

Component Complexity and its Impact on Repair

The relationship between design sophistication and maintenance requirements presents significant challenges. Intricately engineered parts demand specialized knowledge that goes beyond standard technical training, often requiring manufacturer-specific certifications. This specialization creates bottlenecks in repair workflows as qualified technicians become a limited resource.

Physical access constraints compound these challenges, with some critical components buried deep within assemblies. Disassembly sequences must be meticulously followed to avoid collateral damage, significantly extending repair timelines compared to simpler systems.

Repair Difficulty and Required Expertise

The spectrum of repair complexity ranges from straightforward component swaps to intricate system recalibrations. Basic maintenance tasks might require minimal training, but comprehensive system overhauls demand years of specialized experience. This expertise gap creates significant operational challenges for repair facilities balancing workforce development with service demands.

Diagnostic Challenges in Complex Systems

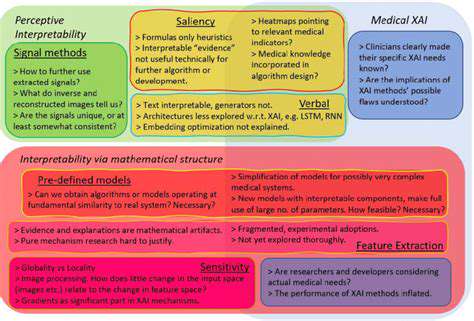

Modern systems integrate so many interdependent components that fault isolation becomes increasingly difficult. Sophisticated diagnostic protocols must account for cascading failures where multiple systems report errors from a single root cause. This complexity often requires iterative testing approaches that extend diagnostic timelines.

Emerging diagnostic technologies like AI-assisted troubleshooting show promise in reducing these challenges. However, their implementation requires substantial training investments and system-specific programming that many shops struggle to justify.

Repair Time and Cost Considerations

The financial implications of complex repairs extend beyond labor hours. Extended equipment downtime creates ripple effects throughout operations, often requiring expensive workarounds to maintain productivity. These hidden costs frequently exceed the direct repair expenses.

Component-specific tooling represents another significant cost factor. Specialized fixtures and calibration equipment often have limited applications, making their acquisition difficult to justify for smaller operations. This creates a competitive advantage for larger service providers who can amortize these costs across higher volumes.

Impact on System Reliability and Availability

Design complexity inherently increases failure modes while reducing mean time between failures. This reliability trade-off forces operators to choose between advanced functionality and operational availability. The most sophisticated systems often require redundant backups to maintain acceptable uptime.

Preventive Maintenance Strategies for Complex Components

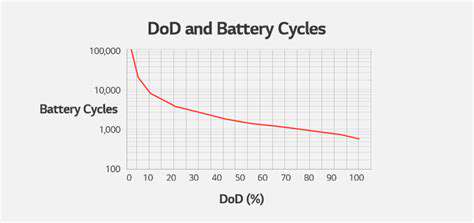

Proactive maintenance philosophies have evolved significantly to address these challenges. Condition-based monitoring systems now provide early warnings by tracking subtle performance deviations long before catastrophic failures occur. This predictive approach maximizes component lifespans while minimizing unplanned downtime.

Standardized maintenance documentation has become increasingly detailed, with manufacturers providing exhaustive checklists and inspection protocols. These resources help technicians identify wear patterns and potential failure points before they impact operations.

Tools and Technologies for Complex Component Repairs

The repair technology landscape continues to advance rapidly. Augmented reality systems now overlay repair instructions directly onto components, reducing interpretation errors and improving first-time fix rates. These tools significantly shorten the learning curve for complex procedures.

Advanced metrology equipment provides micron-level measurement capabilities for precision components. This allows for exacting quality control during repairs that often exceeds original manufacturing tolerances, extending service life beyond design expectations.

Keratin serves as the fundamental building block of hair structure, providing both tensile strength and flexibility. When keratin integrity declines, hair becomes vulnerable to environmental damage and mechanical stress. Proper keratin maintenance requires understanding both internal nutrition and external care regimens to achieve optimal hair health outcomes.

Labor Costs: Specialized Skills and Equipment

Specialized Technician Expertise

The electrification revolution has dramatically transformed automotive service requirements. Modern technicians must master high-voltage safety protocols alongside traditional mechanical competencies. This dual-skill requirement creates significant training challenges as educational institutions work to update curricula for evolving industry needs.

Manufacturer-specific certifications have become increasingly important, with each automaker developing proprietary systems. This specialization fragments the labor pool, making it difficult for independent shops to compete with dealer service centers for qualified personnel.

Advanced Diagnostic Equipment

EV diagnostics require substantial capital investments that many shops struggle to justify. The latest scan tools can cost tens of thousands of dollars, with annual software subscriptions adding ongoing expenses. This creates significant barriers to entry for smaller operations attempting to service modern vehicles.

Equipment obsolescence represents another financial challenge. Rapid technological advancements mean diagnostic tools may become outdated within 3-5 years, requiring continual reinvestment to maintain service capabilities.

Battery Management System (BMS) Repair

BMS technology continues to evolve at a rapid pace, with each generation introducing new complexities. Technicians must understand intricate balancing algorithms and thermal management strategies that vary significantly between manufacturers. This knowledge specialization commands premium labor rates that directly impact repair costs.

Safety considerations add further complexity, requiring specialized isolation procedures and personal protective equipment. These precautions extend repair timelines while increasing both training and operational expenses.

Equipment Calibration and Maintenance

Precision calibration represents an often-overlooked cost factor. High-voltage test equipment requires regular certification to maintain accuracy, with some instruments needing weekly verification. These recurring expenses contribute significantly to overall operational costs.

Technical support contracts have become essential for maintaining diagnostic capabilities. Manufacturer help desks provide critical guidance for complex issues, but their access often comes with substantial subscription fees that smaller operations struggle to absorb.

Training and Certifications

The training infrastructure for EV technicians remains underdeveloped in many regions. Limited training center availability forces technicians to travel extensively for certification courses, adding substantial indirect costs to skills development.

Recertification requirements create ongoing training burdens. Many manufacturer programs require annual refresher courses to maintain certification status, ensuring technicians stay current with evolving technologies but adding to long-term labor costs.

Predicting Future Trends: Cost Considerations for the EV Market

Costco's Expansion Strategy and Market Positioning

Costco's global growth initiatives focus on strategic market selection rather than indiscriminate expansion. The company meticulously analyzes demographic and economic factors to identify locations where their membership model aligns with local consumer behavior. This calculated approach minimizes expansion risks while maximizing long-term profitability potential.

Private label development continues to be a key differentiator. By expanding their Kirkland Signature line, Costco enhances customer value while improving margin structures. This strategy proves particularly effective in international markets where brand recognition provides competitive advantages.

The Impact of Evolving Consumer Demands

Health-conscious shopping trends have accelerated dramatically in recent years. Costco has responded by expanding organic offerings and implementing clearer nutritional labeling throughout their stores. These changes reflect deeper understanding of shifting consumer priorities toward wellness and sustainability.

Digital integration has become increasingly important as members expect seamless omnichannel experiences. Costco's investments in mobile apps and improved website functionality demonstrate recognition of these changing expectations, though challenges remain in integrating these platforms with their warehouse operations.

The Role of Technology and Innovation

Inventory management systems have seen significant advancements. Predictive analytics now help optimize stock levels by analyzing purchasing patterns, seasonal trends, and even local weather forecasts. These tools reduce waste while improving product availability - critical factors in maintaining Costco's value proposition.

Checkout innovations continue to evolve, with self-service options and mobile scanning technologies reducing wait times. These operational improvements enhance customer satisfaction while allowing staff to focus on higher-value interactions throughout the store.

Read more about Exploring Cost Differences in EV Repairs vs. ICE Vehicles

Hot Recommendations

- Offshore Wind for Industrial Power

- Agrivoltaics: Dual Land Use with Solar Energy Advancements: Sustainable Farming

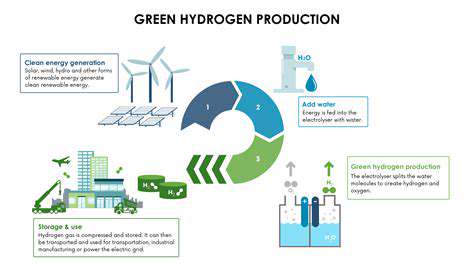

- Hydrogen as an Energy Storage Medium: Production, Conversion, and Usage

- Utility Scale Battery Storage: Successful Project Case Studies

- The Role of Energy Storage in Grid Peak Shaving

- The Role of Startups in Renewable Energy

- The Role of Blockchain in Decentralization of Energy Generation

- The Future of Wind Energy Advancements in Design

- Synchronous Condensers and Grid Inertia in a Renewable Energy Grid

- Corporate Renewable Procurement for Government Agencies