Exploring Hybrid Hydrogen and Electric Power Systems

Introduction to Hydrogen Fuel Cell Technology

Hydrogen fuel cell technology represents a promising pathway towards a more sustainable future, offering a clean and efficient alternative to traditional fossil fuel-based power generation. This technology converts the chemical energy of hydrogen and oxygen directly into electrical energy, producing only water as a byproduct. Understanding the intricacies of hydrogen fuel cells is crucial for evaluating their potential in various applications, from transportation to stationary power generation.

Fuel cell systems are composed of different components, each playing a vital role in the overall process. The core of the system is the electrochemical reaction that takes place within the fuel cell, transforming chemical energy into electrical energy. This process requires a catalyst, typically platinum or platinum-based alloys, to facilitate the reaction.

Electrochemical Reactions in Fuel Cells

The heart of a hydrogen fuel cell lies in the electrochemical reactions occurring at the electrodes. At the anode, hydrogen molecules are oxidized, releasing electrons and protons. These electrons flow through an external circuit, generating electricity, while the protons migrate through an electrolyte membrane to the cathode.

At the cathode, oxygen molecules react with the protons and electrons, producing water as a byproduct. The efficiency of these reactions significantly impacts the overall performance and efficiency of the fuel cell. Optimizing catalyst materials and electrolyte membranes is essential for improving the performance of these systems.

Different Types of Hydrogen Fuel Cells

Several types of hydrogen fuel cells exist, each with its specific characteristics and applications. Proton exchange membrane fuel cells (PEMFCs) are among the most common types, known for their relatively low operating temperatures and high power density. This makes them particularly suitable for transportation applications.

Alkaline fuel cells (AFCs) operate at higher temperatures and have a higher efficiency but are less compact. Solid oxide fuel cells (SOFCs) operate at much higher temperatures and are known for their high efficiency, although their higher operating temperatures introduce some challenges in terms of materials and system design.

Challenges and Limitations of Hydrogen Fuel Cells

Despite the numerous advantages, hydrogen fuel cell technology faces several challenges. One major hurdle is the production of hydrogen, often from fossil fuels, which defeats the environmental benefits of using the technology. Developing sustainable and cost-effective methods for hydrogen production is crucial for widespread adoption.

Another significant concern is the storage and transportation of hydrogen, which requires specialized infrastructure and technologies. The safety of handling and storing hydrogen is also a critical concern due to its flammability.

Hydrogen Production Methods and Sustainability

The sustainability of hydrogen fuel cell technology hinges on the methods used for hydrogen production. Electrolysis using renewable energy sources, such as solar and wind power, is a promising approach for producing green hydrogen, which does not release greenhouse gases during the production process.

Other methods, including reforming natural gas, produce hydrogen but with a significant carbon footprint. The development of efficient and cost-effective electrolysis technologies is crucial for making hydrogen fuel cell technology truly sustainable.

Hydrogen Fuel Cell Applications and Future Prospects

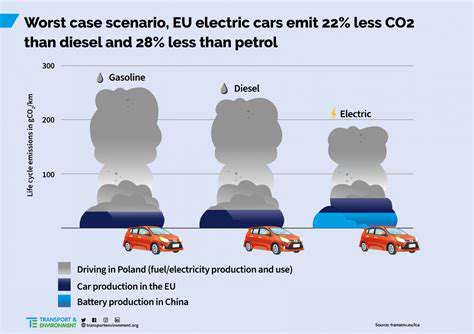

Hydrogen fuel cells have the potential to revolutionize various sectors, from transportation to stationary power generation. In the transportation sector, fuel cell vehicles offer a promising alternative to internal combustion engine vehicles, potentially reducing emissions and improving fuel efficiency.

In stationary power applications, fuel cells can provide a clean and efficient power source, especially in remote areas or locations with limited access to the grid. Further research and development are needed to address the challenges and unlock the full potential of hydrogen fuel cell technology in these diverse applications.

Economic Viability and Infrastructure Development

The economic viability of hydrogen fuel cell technology is closely tied to the cost of hydrogen production, storage, and infrastructure development. Reducing the cost of these components is essential for wider adoption and integration into existing energy systems.

Developing a robust hydrogen infrastructure, including hydrogen production plants, storage facilities, and refueling stations, is crucial for creating a market for hydrogen fuel cell technology. Government policies and incentives can play a significant role in accelerating this transition.

Electric Battery Integration: Enhancing System Flexibility

Improving System Flexibility Through Battery Integration

Electric battery integration plays a crucial role in enhancing the flexibility of hybrid hydrogeothermal systems. By storing excess energy generated during periods of high hydro or geothermal output, batteries allow for better management of fluctuating energy supplies. This capability is particularly important in balancing the intermittent nature of renewable energy sources, allowing for a more consistent and reliable energy output throughout the day and night.

The ability to store energy effectively translates directly into improved system efficiency. This flexibility minimizes the need for expensive backup power sources or energy curtailment, ultimately reducing the overall operational costs of the hybrid system.

Optimizing Energy Management Strategies

Integrating battery storage necessitates the development and implementation of sophisticated energy management strategies. These strategies need to proactively monitor and adjust energy flow between the hydro, geothermal, and battery components of the system. This involves complex algorithms that predict energy demands, assess the real-time availability of each energy source, and optimize the charging and discharging of the batteries to maintain system stability and maximize efficiency.

Efficient energy management is not just about technical optimization; it also involves economic considerations. The strategies need to account for the cost of energy storage, the cost of energy generation from different sources, and the value of the stored energy to the end-user. This requires a holistic approach that balances technical performance with economic viability.

Addressing Technological Challenges in Battery Integration

While the benefits of battery integration are significant, there are technological challenges to overcome. One key challenge is the lifespan and durability of the batteries in the harsh conditions often encountered in hydrogeothermal settings. Extreme temperatures, fluctuating power demands, and environmental factors can all contribute to battery degradation.

Another critical area of concern is the integration of the battery system with the existing hydrogeothermal infrastructure. This requires careful design and engineering considerations to ensure compatibility and seamless operation. The design must also take into account potential safety concerns and the need for appropriate safety protocols.

Exploring Different Battery Technologies for Optimal Performance

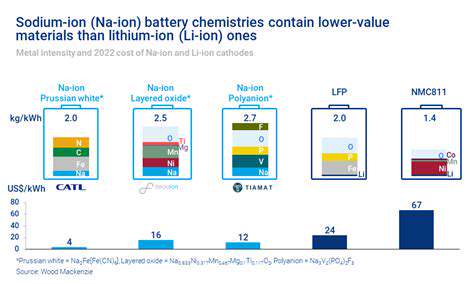

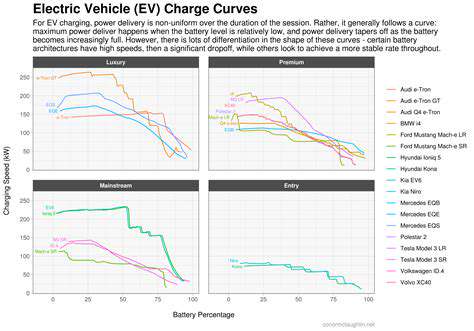

A variety of battery technologies are available, each with its unique characteristics and performance profiles. Lithium-ion batteries, for example, offer high energy density and fast charging capabilities, making them a compelling option for many applications. However, their cost and environmental impact need careful consideration.

Other battery technologies, such as flow batteries, offer potentially longer lifespans and greater resilience to environmental factors. The selection of the appropriate battery technology will depend on specific project requirements, including energy storage capacity, power output, cost, and environmental considerations.

Cost-Benefit Analysis and Economic Viability

A comprehensive cost-benefit analysis is essential to determine the economic viability of incorporating battery storage into a hydrogeothermal system. This analysis should consider the initial capital investment required for the battery system, the ongoing maintenance costs, and the potential savings from reduced reliance on conventional power sources. The analysis should also include a projection of the return on investment over the lifespan of the system.

The analysis needs to factor in potential future energy price fluctuations and the evolving regulatory landscape. Understanding the long-term financial implications is paramount to ensuring the project's economic viability and its contribution to the overall sustainability of the energy system.

Read more about Exploring Hybrid Hydrogen and Electric Power Systems

Hot Recommendations

- Offshore Wind for Industrial Power

- Agrivoltaics: Dual Land Use with Solar Energy Advancements: Sustainable Farming

- Hydrogen as an Energy Storage Medium: Production, Conversion, and Usage

- Utility Scale Battery Storage: Successful Project Case Studies

- The Role of Energy Storage in Grid Peak Shaving

- The Role of Startups in Renewable Energy

- The Role of Blockchain in Decentralization of Energy Generation

- The Future of Wind Energy Advancements in Design

- Synchronous Condensers and Grid Inertia in a Renewable Energy Grid

- Corporate Renewable Procurement for Government Agencies