Exploring Eco Friendly Materials in EV Production

Environmental Impact of Metal Recycling

The ecological benefits of metal recycling are profound. By lessening our dependence on raw materials, we shrink the environmental toll of mining activities. This includes notable reductions in greenhouse gases, preserved habitats, and cleaner waterways—all vital for safeguarding our planet for future generations.

Recycling metals also consumes far less energy than processing virgin materials. This leads to fewer carbon emissions and a more responsible approach to managing our resources. Embracing metal recycling is a crucial stride toward reducing humanity's environmental footprint.

The Future of Recycled Metals in Construction

Construction offers fertile ground for implementing recycled metals. Using recycled steel, aluminum, and other metals in building projects yields cost efficiencies, cuts waste, and softens the environmental blow of conventional construction methods. Incorporating recycled materials into construction allows us to erect structures that are both sustainable and ecologically sound. Pioneering techniques and materials that leverage recycled metals will be instrumental in achieving this vision.

Adopting recycled metals in construction fosters a circular economy, promoting sustainability and resource efficiency in the building sector. This approach delivers environmental dividends while spurring economic growth and job creation within the industry. Breakthroughs in design and engineering will be pivotal in expanding the applications of recycled metals across construction projects.

Before selecting any equipment, carefully evaluate the space you've earmarked for your home gym. Measure the area, note its layout, and identify any potential obstacles like doorways or utility lines that might affect your setup. Addressing these factors during planning prevents costly mistakes and ensures your equipment fits and functions properly. Thoughtful space planning lays the foundation for an effective and enjoyable home workout environment.

Advanced Battery Materials: A Focus on Sustainability

Exploring Lithium-Sulfur Batteries

Lithium-sulfur (Li-S) batteries show great promise as successors to lithium-ion batteries, thanks to their exceptional energy density potential. Sulfur cathodes could enable lighter, more powerful devices. However, technical hurdles persist, particularly with polysulfide instability during charging cycles, which causes capacity loss. Scientists are testing various solutions, from new cathode materials to electrolyte modifications, to enhance Li-S battery durability.

A major research focus involves developing sophisticated sulfur host materials. These specialized materials aim to contain polysulfides, preventing their dispersion and boosting battery performance. Researchers are experimenting with different compositions and structures to effectively manage polysulfide movement, thereby improving cycle life and overall efficiency.

Investigating Solid-State Batteries

Solid-state batteries represent another breakthrough technology, offering potential safety and energy density improvements over conventional batteries. By replacing liquid electrolytes with solid alternatives, these batteries eliminate fire risks while supporting higher voltages—key advantages for safety and longevity.

Creating solid electrolytes with excellent ion conductivity and structural integrity remains paramount. Materials like ceramic oxides and specialized polymers are under scrutiny for their potential to meet these exacting standards. Addressing interface compatibility and ion flow challenges will be crucial for bringing this technology to maturity.

Focusing on Sodium-Ion Batteries

Sodium-ion batteries (SIBs) are emerging as sustainable alternatives to lithium-ion technology. Sodium's greater abundance and lower cost make SIBs potentially more economical. However, sodium ions' slower movement compared to lithium requires innovative electrode and electrolyte designs to compensate.

Examining Post-Lithium-Ion Battery Chemistries

Beyond current technologies, scientists are probing alternative chemistries like magnesium-ion, aluminum-ion, and zinc-ion batteries. Each offers distinct benefits and drawbacks depending on application needs, reflecting the broader search for sustainable energy storage options.

These alternative systems face unique material science and electrochemical challenges. Key research focuses on identifying materials that enable rapid ion transfer while maintaining durability—critical factors for expanding future energy storage possibilities.

Materials Considerations for Sustainable Manufacturing

Sustainable battery production extends beyond active materials to encompass all components. Environmentally conscious manufacturing prioritizes abundant, recycled materials while minimizing rare earth elements. Responsible sourcing and low-impact processing methods are equally important for reducing the ecological footprint of battery production.

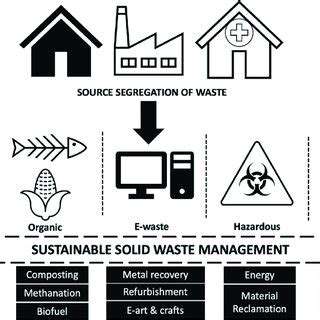

The Role of Recycling and Reuse in Battery Sustainability

Effective recycling forms the cornerstone of sustainable battery systems. Advanced recycling technologies can reclaim valuable materials from spent batteries, reducing reliance on virgin resources and minimizing waste. These closed-loop systems are essential for creating truly sustainable battery lifecycles that mitigate environmental harm.