Exploring Quantum Computing’s Role in EV Innovation

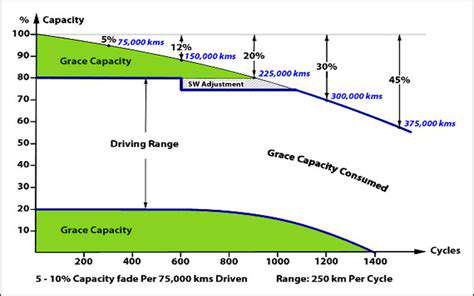

Predictive maintenance techniques are emerging as a powerful tool for optimizing battery performance. By analyzing historical data and real-time performance metrics, algorithms can predict potential battery failures and trigger proactive maintenance measures. This approach will significantly reduce downtime and extend battery lifespan. This proactive approach will have a profound effect on the entire electronics industry. Anticipating problems before they occur is a significant advancement in battery technology.

Quantum-Enhanced Supply Chain Optimization

Quantum Algorithms for Inventory Management

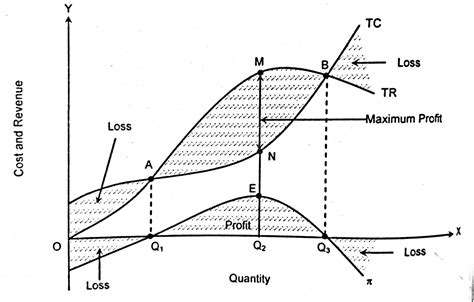

Quantum computing offers the potential to revolutionize inventory management within the electric vehicle (EV) supply chain. Traditional methods often struggle with the complexity of predicting fluctuating demand and optimizing stock levels across numerous components and manufacturing locations. Quantum algorithms, particularly those based on variational quantum eigensolver (VQE) and quantum annealing, can analyze vast datasets of historical sales, production rates, and supplier lead times to identify intricate patterns and correlations that are often missed by classical algorithms. This allows for more precise forecasting, reduced stockouts, and minimized storage costs, ultimately leading to greater efficiency and profitability.

Imagine a scenario where a manufacturer needs to predict the demand for specific EV battery components. By feeding historical data into a quantum algorithm, it can uncover subtle relationships between factors like seasonal trends, economic indicators, and even geopolitical events. This predictive capability allows for proactive adjustments to production schedules, ensuring that the correct components are available when and where they are needed, minimizing delays and maximizing resource utilization. This optimization translates directly into reduced costs and improved supply chain responsiveness.

Quantum Simulation of Manufacturing Processes

Quantum simulation can model the intricate physical processes involved in EV manufacturing. This includes simulating the behavior of materials under various conditions, such as temperature and pressure, during battery production, component assembly, and vehicle finalization. Traditional simulation methods often rely on simplified models that can't fully capture the complexities of real-world processes. Quantum simulation can provide a more accurate picture, enabling engineers to design more efficient processes, optimize material usage, and reduce waste. This translates into enhanced manufacturing quality and reduced production costs.

For example, simulating the thermal management system of an EV battery pack allows engineers to identify areas of potential failure points and optimize the cooling system design. This process can be incredibly complex with numerous variables affecting thermal conductivity, heat transfer, and material properties. Quantum simulation can help to model these complex interactions with greater accuracy, leading to more robust and efficient designs.

Quantum-Enhanced Supplier Network Optimization

Optimizing the supplier network for EV components is a crucial aspect of supply chain optimization. Quantum algorithms can analyze the vast network of suppliers, considering factors like lead times, delivery costs, and quality standards. This analysis can identify bottlenecks, optimize routes, and ensure reliable delivery of components throughout the manufacturing process. This approach can significantly reduce delivery times and lead to a more resilient supply chain, ensuring consistent product flow and minimizing disruptions.

By leveraging quantum computing, companies can identify optimal supplier partnerships and ensure that their network effectively responds to fluctuations in demand and supply. This proactive approach to supplier network optimization can mitigate risks associated with geopolitical events, natural disasters, or unexpected disruptions. The result is a more agile and reliable supply chain capable of adapting quickly to changing circumstances and ensuring a stable supply of essential EV components.