Generative AI for Personalized Customer Engagement in Logistics

Predictive order management is a powerful approach that leverages data analysis and machine learning algorithms to forecast future order patterns and optimize inventory levels and resource allocation. This forward-thinking strategy allows businesses to anticipate customer demand more accurately, reducing the risks associated with stockouts and overstocking. By proactively adjusting inventory levels and supply chain processes, companies can ultimately streamline their operations and improve profitability.

This advanced approach to order management goes beyond reactive responses to orders. It anticipates future needs, enabling businesses to optimize their entire supply chain, from procurement to delivery. The benefits extend beyond simple cost savings, as it promotes better customer satisfaction through on-time delivery and enhanced service levels.

Key Components of Predictive Order Management

Several key components contribute to the effectiveness of a predictive order management system. These include sophisticated forecasting models, often employing machine learning, that analyze historical sales data, market trends, and external factors to predict future demand. Furthermore, robust data integration systems are essential for collecting and processing data from various sources, including sales, marketing, and inventory management systems.

Accurate data is paramount to the success of predictive order management. Inaccurate data can lead to poor forecasts and suboptimal decisions. Therefore, a system must be reliable and capable of handling a high volume of data.

Real-time order tracking and visibility across the supply chain are also crucial. This allows for dynamic adjustments to inventory and logistics based on real-time demand fluctuations and potential disruptions.

Benefits of Implementing Predictive Order Management

The advantages of implementing predictive order management are numerous and significant. Improved inventory management is a primary benefit, as it reduces the risk of stockouts and overstocking. This results in substantial cost savings by optimizing inventory holding costs and minimizing waste.

Reduced operational costs and improved efficiency are other key benefits. Proactive adjustments to inventory and supply chain processes minimize delays and increase the overall speed of order fulfillment. This directly impacts customer satisfaction by ensuring timely delivery.

Enhanced customer satisfaction is a crucial outcome of predictive order management. Consistent on-time delivery and improved order fulfillment contribute to customer loyalty and positive brand perception. Ultimately, this leads to increased revenue generation.

Challenges in Implementing Predictive Order Management

While predictive order management offers numerous benefits, challenges exist in its implementation. One key challenge is the need for significant data collection and integration from various sources. A robust data infrastructure is essential to support the complex algorithms and models required for accurate forecasting.

Another challenge involves the initial investment required for the implementation of new technologies and software. The cost of implementing predictive order management systems can be substantial, potentially impacting the budget of smaller businesses. Furthermore, the requirement for skilled personnel with expertise in data analysis and machine learning is often cited as a significant hurdle.

Future Trends in Predictive Order Management

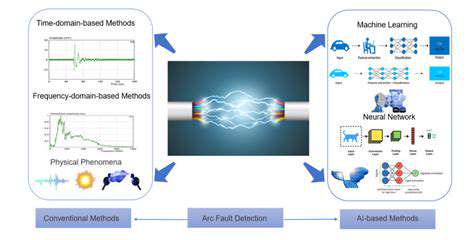

The field of predictive order management is constantly evolving, with emerging trends shaping its future. The increasing use of artificial intelligence (AI) and machine learning (ML) is driving the development of more sophisticated forecasting models. The integration of real-time data from various sources, including IoT devices and social media, is expected to enhance the accuracy of predictions.

The development of more user-friendly interfaces and intuitive dashboards is another key trend. This will allow businesses to easily access and interpret the insights generated by predictive order management systems, enabling quicker decision-making and improved responsiveness to changes in demand.

The integration of predictive order management with other supply chain technologies, such as blockchain and cloud computing, will further enhance its capabilities and efficiency in the future.

Ask yourself if you've accessed the file in the last year, or if it's a file you've only needed once or twice. If the answer is no, it might be time to consider discarding or archiving it.

Beyond the Basics: Future Applications of Generative AI in Logistics

Generative AI for Optimized Supply Chains

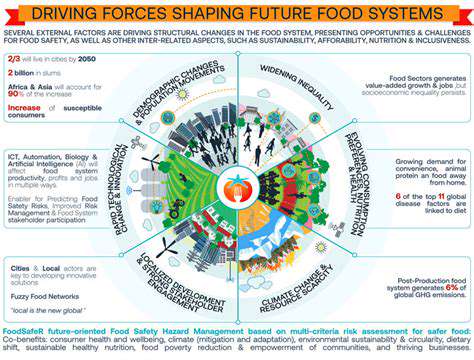

Generative AI holds immense promise for revolutionizing supply chain management by automating and optimizing complex logistical processes. Imagine a system that can predict potential bottlenecks in real-time, dynamically adjust delivery routes based on real-time traffic and weather conditions, and even suggest alternative transportation modes to minimize costs and delivery times. This level of predictive and proactive optimization is a significant leap forward from traditional logistics models, ultimately improving efficiency and reducing operational costs for businesses across various industries.

Beyond simply optimizing existing processes, generative AI can also be instrumental in designing entirely new logistics solutions. For instance, it can help companies create innovative warehousing layouts, predict the optimal inventory levels to maintain, and even generate customized packaging designs for improved efficiency and sustainability. This forward-thinking approach empowers businesses to adapt to changing market demands and emerging trends much more effectively.

Personalized Customer Experiences through AI-Powered Logistics

Generative AI has the potential to transform the customer experience within the logistics sector. Imagine a system that anticipates customer needs, suggests optimal delivery windows, and provides personalized tracking updates throughout the shipping process. This level of customization and transparency will significantly enhance customer satisfaction and loyalty, creating a competitive advantage in a market increasingly focused on personalized experiences.

Furthermore, generative AI can be leveraged to create personalized communication strategies. AI-powered systems can generate tailored messages to customers, informing them about delivery updates, potential delays, and even offering proactive solutions to address any concerns. This proactive and personalized communication fosters trust and strengthens relationships with customers, crucial for building brand loyalty in a digitally driven world.

Ethical Considerations and Responsible Development of Generative AI in Logistics

While the potential benefits of generative AI in logistics are substantial, it's crucial to address the ethical considerations that come with such powerful technology. The deployment of generative AI systems must be guided by principles of fairness, transparency, and accountability to ensure that these systems do not perpetuate existing biases or create new inequities within the supply chain. Careful consideration must also be given to data privacy and security, ensuring that sensitive information is handled responsibly and ethically.

Moreover, the ongoing development of generative AI in logistics needs to prioritize human oversight and control. While AI can automate many tasks, human expertise and judgment will remain essential in critical decision-making processes. Collaboration between humans and AI systems is key to harnessing the full potential of this technology while mitigating potential risks and ensuring responsible implementation.

The development of robust regulatory frameworks and ethical guidelines is essential to ensure that generative AI systems are deployed responsibly and ethically within the logistics sector. Continuous monitoring and evaluation of these systems, along with ongoing dialogue between stakeholders, will be crucial for navigating the complex ethical landscape of this rapidly evolving field.