The Impact of AI on Supply Chain Data Quality and Integrity

The Rise of AI in Supply Chain Data Management

AI-Powered Data Collection and Aggregation

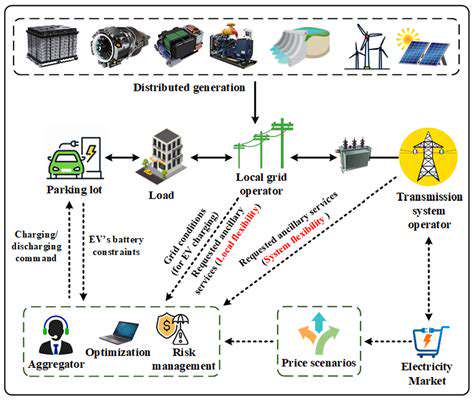

Modern supply chains are undergoing a seismic shift as Artificial Intelligence (AI) becomes deeply embedded in data management practices. Cutting-edge AI systems now autonomously gather critical data from a sprawling network of sources, ranging from traditional ERP and WMS platforms to unconventional streams like social sentiment analysis and hyperlocal weather patterns. This technological leap eliminates tedious manual processes, virtually eradicates transcription errors, and creates unprecedented visibility across supply chain operations.

The magic happens in the system's ability to synthesize these diverse data streams into coherent, actionable insights. Where human analysts might struggle to connect the dots between warehouse inventory levels and regional weather disruptions, AI effortlessly identifies these correlations, providing supply chain managers with a multidimensional view of their operations.

Predictive Analytics for Enhanced Forecasting

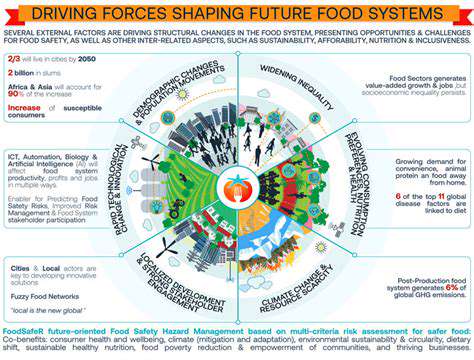

Modern supply chain professionals increasingly rely on AI's pattern recognition capabilities to stay ahead of potential disruptions. These systems digest years of historical data to forecast everything from seasonal demand spikes to potential supplier bottlenecks. This foresight enables companies to implement strategic buffer stocks or alternative sourcing arrangements weeks before problems materialize, transforming supply chain management from reactive to proactive.

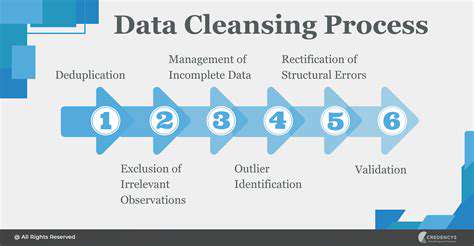

Improved Inventory Management and Optimization

Gone are the days of static inventory models. Today's AI-driven systems perform continuous calculus, balancing real-time sales velocity against production lead times and seasonal trends. The result is a dynamic inventory strategy that maintains just enough stock to meet demand without tying up capital in excess inventory. Retail giants report 30-40% reductions in stockouts while simultaneously decreasing carrying costs by similar margins.

Automated Order Fulfillment and Logistics

The fulfillment revolution is here. AI systems now orchestrate complex logistics ballet - analyzing thousands of variables from fuel prices to traffic patterns to determine optimal shipping routes. These systems don't just react to changes; they anticipate them, rerouting shipments around potential weather disruptions before the first raindrop falls. The outcome? Delivery times slashed by days and customer satisfaction scores soaring.

Real-Time Visibility and Enhanced Decision Making

Modern AI dashboards have evolved into mission control centers for supply chain operations. Managers no longer make decisions based on yesterday's data, but rather on what's happening right now across their global network. When a shipment gets delayed at a port in Shanghai, Chicago headquarters knows instantly and can adjust production schedules accordingly. This real-time responsiveness has become the new competitive benchmark in logistics.

Demand Forecasting and Resource Allocation

AI's predictive capabilities extend far beyond simple sales projections. Sophisticated models now account for macroeconomic indicators, social media trends, and even political developments to forecast demand with startling accuracy. Manufacturers using these systems report near-perfect alignment between production schedules and actual demand, eliminating both costly overproduction and revenue-killing stockouts.

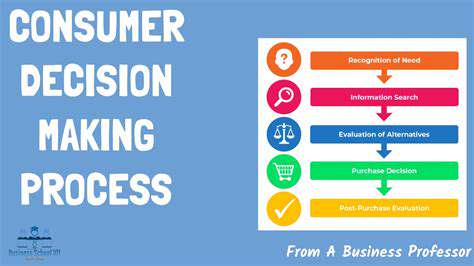

Enhanced Customer Service and Satisfaction

The AI revolution reaches all the way to the end customer. Modern systems don't just track shipments - they predict potential delays before they occur and automatically trigger proactive customer communications. This anticipatory service transforms what could be frustration into customer delight, with some retailers reporting improved Net Promoter Scores despite occasional logistical challenges.

Read more about The Impact of AI on Supply Chain Data Quality and Integrity

Hot Recommendations

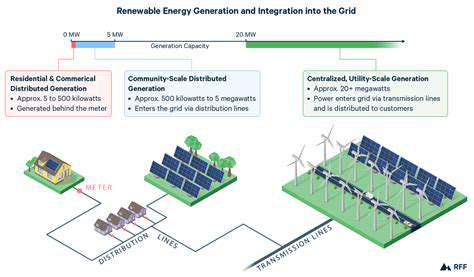

- Offshore Wind for Industrial Power

- Agrivoltaics: Dual Land Use with Solar Energy Advancements: Sustainable Farming

- Hydrogen as an Energy Storage Medium: Production, Conversion, and Usage

- Utility Scale Battery Storage: Successful Project Case Studies

- The Role of Energy Storage in Grid Peak Shaving

- The Role of Startups in Renewable Energy

- The Role of Blockchain in Decentralization of Energy Generation

- The Future of Wind Energy Advancements in Design

- Synchronous Condensers and Grid Inertia in a Renewable Energy Grid

- Corporate Renewable Procurement for Government Agencies