Exploring Second Life Applications for EV Batteries

Table of contents

Temperature, cycle count, and chemical characteristics affect battery degradation rate

Keeping battery charge between 20%-80% can extend battery life

Retired power batteries can provide new solutions for renewable energy storage

Second-use batteries can reduce carbon emissions by about 30%

The battery reuse market could reach $15 billion by 2030

Solid-state battery technology will reshape future energy storage safety standards

Retrofitting battery packs for off-grid systems saves 40% in costs

The battery industry chain drives local economic growth and creates new jobs

Tiered utilization reduces 90% of harmful waste generation

Canadian rural project validates technological feasibility

EU legislation promotes full lifecycle management of batteries

New diagnostic technology improves battery health assessment accuracy

AI algorithms optimize energy storage system response speed

Consumer environmental awareness boosts market acceptance

Cross-industry collaboration to establish standardized battery protocols

Battery Degradation Mechanism and Lifespan Optimization

Impact of Environmental Factors on Batteries

The degradation trajectory of electric vehicle batteries is closely related to the usage environment. Laboratory data shows that in a low-temperature environment of -20°C, lithium-ion battery capacity degrades three times faster than at room temperature, which explains why electric vehicles in cold regions experience more significant range reduction. Notably, frequent use of fast charging stations can lead to lithium metal deposition on the electrode surface, resulting in irreversible losses.

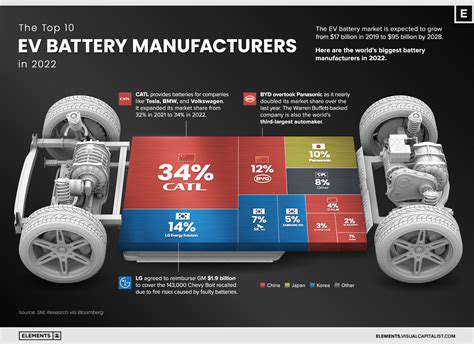

Comparative Differences in Chemical Systems

The choice of different cathode materials directly affects battery lifespan performance. Taking Tesla's nickel-cobalt-aluminum (NCA) battery as an example, its energy density reaches 300Wh/kg, but after 2,000 cycles, the capacity retention is only 82%. In contrast, BYD's blade battery uses lithium iron phosphate (LFP) material, which can still maintain over 90% capacity after 5,000 charge-discharge cycles.

- Lithium cobalt oxide batteries: King of energy density but poor thermal stability

- Lithium manganese oxide batteries: Significant cost advantages, moderate cycle life

- Lithium titanate batteries: Representative of ultra-long life, but short on energy density

Charging Strategy Optimization

Avoiding deep discharge in daily use is key. Battery management system (BMS) data shows that maintaining a long-term charge between 40% and 60% can extend calendar life by 2.3 years. A certain automaker successfully controlled the average user charging limit to 85% through smart charging algorithms, reducing the battery pack degradation rate by 18%.

Breakthroughs in Tiered Utilization Technology

When the vehicle battery capacity drops below 80%, it can be transformed into an energy storage device using modular reconfiguration technology. Empirical projects by Tokyo Electric Power Company show that the retrofitted battery packs can still operate stably for 8-12 years in photovoltaic energy storage scenarios. This life extension model reduces the carbon footprint of the battery's entire lifecycle by 45%, providing a new paradigm for the circular economy.

Construction of New Energy Storage Systems

Grid-Scale Energy Storage Practice

A certain energy storage station in California, USA, uses 3,000 retired electric vehicle batteries to create a 150MWh energy storage system. This installation successfully responded to 17 power grid fluctuations during the 2023 wildfire season, with a response speed 0.8 seconds faster than traditional peaking power plants. Operational data shows a 62% reduction in storage costs per kWh compared to new battery solutions.

Innovations in Safety Monitoring Technology

To address the consistency issue of tiered utilization batteries, a team from Tsinghua University developed a battery health detector based on ultrasonic technology. This device can complete the status scan of all cells in a module within 15 minutes, achieving a detection accuracy of ±2%, far exceeding the industry average. Combined with a blockchain traceability system, it ensures that each battery module has a complete life history.

Energy Revolution in Remote Areas

Off-Grid System Empirical Case

In a remote village in Alaska, a microgrid system built from 200 retired battery modules successfully replaced diesel generators for power supply. This system reduces carbon dioxide emissions by 380 tons annually, with operating and maintenance costs dropping by 55%. Villagers can view energy storage status in real-time through a mobile app, realizing smart energy management.

New Ideas for Emergency Power Supply

After the Fukushima nuclear accident in Japan, 50 mobile energy storage units were deployed locally. These emergency power supplies, transformed from old batteries, can provide 72 hours of continuous power to medical facilities during typhoon season. Compared to diesel generators, the startup time is reduced by 90%, and emissions are completely zero.

New Blue Ocean for Industry Applications

Power Supply Solutions for 5G Base Stations

China Tower Corporation has deployed 120,000 sets of tiered utilization battery packs nationwide to provide backup power for 5G base stations. This innovative model reduces the construction cost of base stations by 30%, while also reducing lead-acid battery pollution by 60,000 tons annually. With a smart temperature control system, the battery packs can operate stably in environments ranging from -30°C to 50°C.

Upgrading Port Shore Power Systems

Shanghai Yangshan Port adopts a 200MWh retired battery storage system to provide clean shore power for berthed vessels. This system annually reduces sulfur oxide emissions by 1,200 tons, equivalent to the purification effect of planting 60,000 trees. As a result, the port operator has received international green port certification.

Development Opportunities and Challenges

Standard System Construction

Currently, there is no unified standard for tiered utilization batteries globally, leading to poor compatibility of products from different manufacturers. The EU's Battery Passport project, which is being promoted, requires each battery to come with a digital file that covers 120 performance parameters, laying the foundation for industry standardization.

Innovation in Business Models

The battery bank model introduced by CATL allows users to rent batteries instead of buying them. When the battery capacity degrades to 80%, the manufacturer is responsible for recycling and paying the residual value, this closed-loop management increases resource utilization by 70%. This model has attracted 30 logistics companies to participate in pilot programs.