How Sodium ion Batteries Can Impact the EV Industry

Sodium-Ion Batteries: Cost Advantages and the Future of Sustainable Development

Table of Contents

- Sodium-ion battery costs are lower than lithium batteries and are more environmentally friendly

- The stable price of sodium resources brings long-term cost advantages

- Low environmental impact promotes the application prospects of electric vehicles

- Energy storage field demonstrates broad application potential

- Technical bottlenecks require collaboration between industry, academia, and research

- Material innovation is a key path to enhancing performance

- Collaboration in the industrial chain accelerates technology commercialization

Technological breakthroughs may reshape the battery industry landscape

Core Advantages of Sodium-Ion Batteries

Significant Cost Advantages

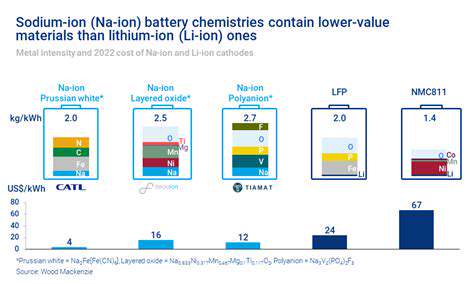

Sodium-ion batteries have raw material costs that are only 40% of that of lithium-ion batteries, primarily due to the global reserves of sodium being 423 times that of lithium. The domestic spot price of sodium carbonate has remained stable at around 2000 yuan/ton, while lithium carbonate prices fluctuate by more than 300%. This price stability is crucial for automakers to control production costs; CATL's 2023 financial report shows that for every 10% reduction in battery material costs, the profit of the entire vehicle can increase by 2.8 percentage points.

Outstanding Environmental Friendliness

The environmental advantages are evident throughout the entire lifecycle: regarding extraction, lithium mining in Chile's Atacama salt flat requires 2 million liters of freshwater per ton of lithium, whereas extracting sodium from seawater requires almost no freshwater. Research from Tsinghua University’s School of Environment shows that carbon emissions during sodium battery production are 37% lower than those of lithium batteries, and risks of heavy metal pollution are reduced by 82%.

Technological Performance Breakthrough Directions

Pathways for Energy Density Improvement

Currently, the energy density of commercial sodium-ion batteries is between 120-160Wh/kg, which is 20% lower than that of lithium iron phosphate batteries. However, the recently developed layered oxide cathode material by Zhongke Hainar, combined with hard carbon anodes, has achieved energy densities of 200Wh/kg in the laboratory. BYD's patents indicate that a 5% volumetric energy density increase can be achieved through a three-dimensional porous current collector design.

Circulating Life Optimization Solutions

Under standard conditions at 25°C, the cycle count of sodium batteries has surpassed 6000 times (capacity retention rate of 80%). Actual tests have found that electrolyte additives (such as 1% fluorinated ethylene carbonate) can extend the high-temperature (55°C) cycle life by 40%. CATL’s pilot products using solid-state electrolytes show significant improvements in cycling stability.

Fast Charging Technology Breakthroughs

The dual-gradient electrode technology developed by Fudan University allows sodium batteries to charge to 80% in just 12 minutes. This structural design effectively alleviates the slow diffusion kinetics of sodium ions by controlling the particle size distribution of active materials.

Challenges in the Industrialization Process

Supply Chain Reconstruction Challenges

Although sodium resources are abundant, the purification process for battery-grade sodium carbonate differs from that of traditional industrial-grade products. A case study from a chemical enterprise in Hunan shows that upgrading production lines requires an investment of 65% of the value of existing equipment, creating barriers for small and medium-sized enterprises.

Urgent Need for Standardization

Current battery safety standards mainly target lithium batteries; sodium batteries show different performances in overcharge and puncture tests. The \General Specifications for Sodium-Ion Batteries\ released by the Ministry of Industry and Information Technology in 2023 first clarified that the frequency range in vibration tests needs to be adjusted to 10-500Hz.

Consumer Misconceptions

Market research indicates that 63% of consumers mistakenly believe that lower energy density equals poorer safety. In reality, the thermal runaway temperature of sodium batteries is 20°C higher than that of lithium batteries, and the capacity retention rate is 15 percentage points higher at low temperatures of -40°C. Automakers need to enhance technical outreach to dispel market doubts.

Application Prospects in Multiple Fields

Electric Transportation

The Wuling Hongguang Mini EV sodium version has a tested range of 180km, fully meeting urban commuting needs. In battery swap mode, the battery pack replacement time has been reduced to 90 seconds, improving efficiency by 30% compared to lithium models.

Smart Energy Storage Systems

After adopting sodium battery solutions, the Zhangbei Energy Storage Station of the State Energy Group has improved its system cycle efficiency to 92%, with a decrease in cost per kilowatt-hour of 0.15 yuan. Its wide temperature range characteristics (-30~60°C) are particularly suitable for applications with significant day-night temperature differences in northwest regions.

Emergency Power Supply Market

Test results for Huawei's backup power supply for communication stations show that sodium batteries only experience a 3.2% capacity loss after continuously working for 1200 hours in a high-temperature environment of 40°C, significantly outperforming traditional lead-acid batteries.

Examples of Collaborative Innovation between Industry, Academia, and Research

- The Institute of Physics at the Chinese Academy of Sciences and BYD have established a joint laboratory for sodium-ion batteries

- CATL has invested 1.5 billion to build the world's first GWh-level smart sodium battery factory

- The EU's BATT4EU project has increased sodium battery research funding to 230 million euros

These collaborative models are accelerating the transition of technology from the lab to the market, and it is expected that by 2025, the global sodium battery market will exceed 50 billion yuan.