Premium Electric Vehicles with Cutting Edge Technology

The Historical Evolution and Technological Innovations of Electric Mobility

The Transformation Journey of Electric Vehicles

A Century of Power Revolution

When Scottish inventor Robert Anderson fitted an electric motor to a carriage in 1832, no one could have predicted that this idea would ignite a global industrial revolution two hundred years later. Early electric carriages occupied 38% of the U.S. automotive market share at one point, thanks to their zero emissions and low noise advantages. The electric taxi fleets on the streets of New York and Thomas Edison’s personal involvement in battery research are testaments to this forgotten brilliance.

The technological breakthroughs of internal combustion engines acted like a double-edged sword, revolutionizing mobility while silencing electric technology for half a century. It wasn’t until the oil crisis of 1973 that General Motors’ EV1 reignited hopes. Although this aluminum-bodied two-seater sports car was ultimately destroyed, it laid the groundwork for future developments.

Breakthrough Advances in Core Technology

The launch of the Tesla Roadster in 2008 fundamentally rewrote the rules of the game. Built on the Lotus Elise chassis, this electric sports car features an energy matrix made up of 6831 notebook batteries, achieving a range exceeding 320 kilometers, shattering the preconceived notion that electric cars could only be used for short trips. More importantly, the active battery management system it employs can monitor the status of each cell in real time, and this patented technology remains the industry benchmark today.

The intelligent evolution of energy recovery systems is equally impressive. Modern models can automatically adjust recovery intensity based on navigation predictions of terrain—enhancing recovery on downhill segments and diminishing it on flat sections. This predictive energy management can boost actual range by 15%. When drivers release the accelerator, the system functions like an experienced sailor, precisely capturing every gust of wind energy.

The Synergy of Policy Levers and Market Gears

The myth of electric vehicle proliferation in Norway best illustrates the power of policy. By combining measures such as exempting 25% value-added tax and allowing the use of bus lanes, this Nordic country achieved an electric vehicle share of 87% in 2022. What’s more intriguing is Tesla's Model Y from the Berlin factory, which became the best-selling model locally in just six months, thanks to Germany's environmental subsidy policies, depicting a reversal of American brands conquering the German market.

The Subtle Shift in Consumer Psychology

According to the latest survey by J.D. Power, 72% of consumers list charging convenience as their primary consideration, up from just 43% three years ago. NIO's battery swap model and XPeng's supercharging network are both attempting to overcome this psychological barrier. Interestingly, among Porsche Taycan owners, 38% transitioned from traditional fuel-powered sports cars, confirming that performance is breaking market segmentation.

The Evolution of the Power Heart

Limit Breakthroughs in Lithium Battery Technology

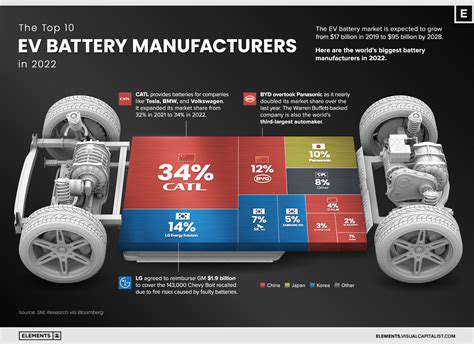

CATL's Kirin battery has pushed the volume utilization rate to 72%, equivalent to installing 20% more energy units in the same space. The secret lies in its innovative multi-functional elastic interlayer design, which fixes battery cells while also serving as a heat dissipation channel. This structural innovation enables the Tesla Model 3 to achieve a range exceeding 600 kilometers, equivalent to the one-way distance from Beijing to Zhengzhou.

The Dawn of Solid-State Batteries

Toyota's recently unveiled solid-state battery prototype maintains 90% range even in -30°C conditions, thanks to the excellent low-temperature performance of sulfide solid electrolytes. More crucially, its 10-minute fast charging technology triples ion migration speed by incorporating special lithium salts into the electrolyte. Although mass production still faces challenges with interfacial resistance, it has already illuminated hope for the industry.

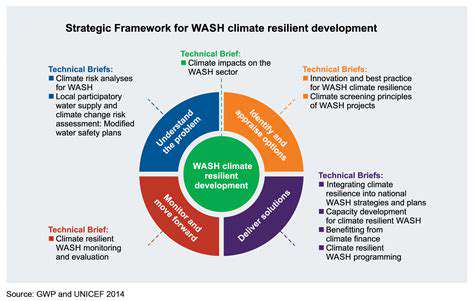

The Green Closed Loop of Battery Regeneration

BYD's blade battery regeneration plan has created a new model—decommissioned batteries are deteched, reorganized, and transformed into storage station cell units. The practice at the Shenzhen Baoqing battery storage station demonstrates that this tiered utilization can reduce carbon emissions in the entire battery lifecycle by 40%. More impressively, the purity of recycled metals reaches 99.93%, exceeding that of mining by 0.15%.

The Experience Revolution of Intelligent Cockpits

The Philosophical Transformation of Interaction Design

The tri-screen design of the Li Auto L9 conceals intricacies: the driver’s screen uses anti-glare frosted glass, the central control screen employs high-transparency glass, and the passenger screen is coated with a blue light filter. This scenario-based material selection optimizes the visual experience from different positions. Even more astounding is its TOF gesture sensor, capable of recognizing 21 gestures with a margin of error of just 3 millimeters, comparable to professional motion-sensing devices.

Infinite Possibilities in Ecological Integration

Huawei's HarmonyOS cockpit interconnectivity with drones serves as a prime example. In the Wenjie M9, a light tap on the screen summons a drone for reconnaissance, with real-time footage transmitted via 5G, automatically planning scenic routes based on road conditions. This air-ground collaborative navigation not only expands travel dimensions but also creates entirely new ways to experience tourism.

A New Paradigm of Sustainable Luxury

The Polestar Precept concept car features seats created with 3D flying-edge knitting technology, which can reduce material waste by 800 grams per set. The flax composite materials used are as strong as carbon fiber but have only one-fifth of the carbon footprint. This dance of technology and craftsmanship is redefining the essence of luxury—it's not about resource waste but a crystallization of wisdom.