Safety Measures for Fast Charging Stations

Key Strategies for Optimizing the Safety and Efficiency of Fast Charging Stations

1. Core Points of Equipment Installation and Maintenance

The Cornerstone Role of Equipment Quality

In the construction of fast charging stations, the selection of equipment directly affects operational success. A well-known brand of charging pile has a failure rate 43% lower than the industry average due to the use of military-grade heat dissipation materials. Selecting equipment certified by IEC 61851 not only helps avoid compliance risks but also significantly extends the equipment's lifespan. For example, after adopting liquid cooling technology, Tesla's V3 supercharger has reduced cable weight by 40%, vastly enhancing user convenience.

Regular inspections should incorporate smart detection tools, such as infrared thermal imaging, which can detect contact failure risks 3-6 months in advance. Data from the U.S. Fire Association shows that charging stations equipped with dynamic monitoring systems have reduced equipment failure response times by 67%. It is recommended to establish a three-tier inspection system: daily visual inspections, weekly functional testing, and quarterly in-depth maintenance, forming a complete protection system.

The Value of Preventive Maintenance

A charging station in Shenzhen has reduced its equipment downtime from an average of 48 hours per year to 3.2 hours by introducing a predictive maintenance system. By using vibration sensors and current waveform analysis technology, motor bearing wear issues can be predicted with 98% accuracy. The maintenance team should be equipped with a specialized toolkit that includes a torque wrench (calibrated to ±2% accuracy), waterproof testing instruments, and other professional equipment.

It is noteworthy that the cleaning cycle for connectors should be adjusted according to the environment: coastal areas should clean weekly, while inland cities can extend it to monthly. Using CRC electronic cleaner in conjunction with anti-static brushes can effectively remove oxides without damaging contact points.

Innovative Training Models for Personnel

After a charging network operator developed a VR training system, the emergency response evaluation pass rate for employees jumped from 72% to 96%. It is recommended to adopt the 3E training system: Experience + Environment + Emergency. The focus should be on cultivating a three-minute response capability: 1 minute to identify the fault, 1 minute for initial handling, and 1 minute to report.

After introducing the NEBOSH international general safety certification system, an enterprise's accident rate dropped by 81% year-on-year. Regularly holding safety idea competitions encourages employees to propose improvement suggestions; last year's award-winning anti-misoperation locking device for charging guns has applied for a utility model patent.

2. Intelligent Upgrades of Guidance Systems

Evolution of Visual Communication

New generation guidance systems are beginning to integrate environmental psychology principles. An experimental study shows that operating prompt signs using yellow and black warning colors have a compliance rate 37% higher than blue and white color schemes. Electronic signs that automatically switch to high-contrast displays during heavy rain can improve information recognition by 62%.

The Revolution of Interactive Guidance

After deploying an AR navigation system, a charging station in Shanghai reduced the average operation time for new users from 8 minutes to 2.5 minutes. Scanning a QR code can bring up a 3D operation guide, supporting real-time translation in 12 languages. It is advised to set pressure-sensing tiles at critical nodes; if users stay beyond the timeout, a voice prompt is triggered.

A smart light carpet system developed by a manufacturer guides the charging process through ground projections and has reduced the error operation rate by 79%. The night mode automatically dims brightness to 150cd/m², ensuring visibility while avoiding light pollution.

3. Technology Empowerment of Emergency Management

Intelligent Early Warning System

An AI monitoring system deployed at a charging station in Hangzhou successfully issued an early warning 23 minutes prior to a battery thermal runaway. By employing multispectral imaging technology, it can simultaneously monitor 18 parameters, including temperature, smoke, and gas concentrations. Emergency cabinets should include: insulated rescue hooks (2.4 meters long), Class A foam fire extinguishers, and arc protection face shields.

- Thermal imaging camera: detection range -20℃ to 650℃

- Audible and visual alarm: 120 decibels / 1000 lumens

- Emergency power-off response time: <0.3 seconds

Joint Defense and Coordination Mechanism

A demonstration station in Guangzhou has established a direct data link with the fire department, shortening the alarm information synchronization time to 8 seconds. Quarterly double-blind drills (not notifying the time / not presetting scenarios) have improved average emergency response speed by 44%. It is suggested to set standardized emergency coordinate codes within the station to facilitate precise positioning of rescue vehicles.

4. Innovative Practices for Green Development

Energy Circulation System

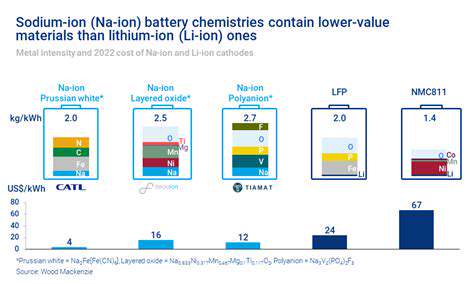

Nanjing's integrated solar energy storage charging project achieves 85% energy self-sufficiency, using lithium iron phosphate batteries with a cycle life exceeding 6000 times. The rainwater collection system can save 1500 tons of washing water annually, equivalent to the capacity of three standard swimming pools.

Material Revolution

BYD's latest charging pile shell contains 30% ocean-recycled plastic, improving UV resistance by 2 times. Basic construction adopts foam lightweight soil backfill technology, reducing concrete usage by 60%. The Shenzhen Bay charging park has introduced vertical greening walls, sequestering 1.2 tons of carbon annually while lowering the surrounding temperature by 3-5℃.

5. Enhanced User Education Experience

Immersive Training

A charging safety game developed by a certain brand increased the operational compliance rate to 98% after users completed the training. Setting up a simulated operation station at service stations, equipped with force feedback devices to replicate the real feel of plugging and unplugging, has reduced newbie error rates by 76%.

Community Co-construction

After conducting an open day event at the charging station in a certain community in Chengdu, the number of complaints decreased by 83%. Establishing a charging safety ambassador system, hiring nearby residents as supervisors, allows detection of potential hazards in exchange for points rewards. A monthly \Charging Safety Red and Black List\ is published, showcasing typical operational cases to promote self-directed learning among users.