The Role of Hydrogen Fuel Cells in Sustainable Mobility

Catalog

Reduce greenhouse gas emissions through hydrogen fuel cells, contributing to the fight against climate change.

The energy efficiency of fuel cells surpasses traditional internal combustion engines, ushering in a new era of efficient power.

Hydrogen energy infrastructure construction is creating new opportunities for economic growth and employment.

Technological innovations are driving improvements in fuel cell vehicle performance and cost reductions.

Zero-emission characteristics significantly improve urban air quality and reshape livable environments.

Industry forecasts indicate explosive growth for the hydrogen fuel cell vehicle market.

We need to overcome the triple challenges of manufacturing costs, infrastructure gaps, and public perception.

Cross-sector collaboration is the key driving force for breakthroughs in hydrogen energy technologies.

Analysis of Environmental Benefits of Hydrogen Fuel Cells

Practical Effects of Greenhouse Gas Emission Reduction

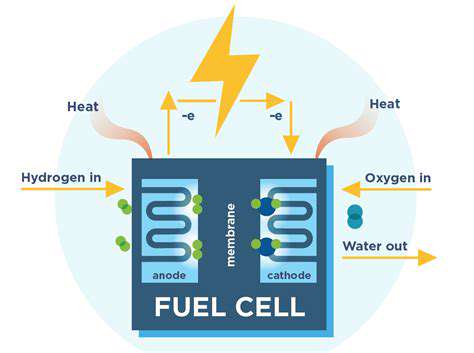

When people discuss clean energy, hydrogen fuel cells are always a topic that cannot be avoided. The most striking feature of this technology is that its chemical reaction only produces water vapor, completely avoiding the drawbacks of traditional fuel vehicles which emit carbon dioxide and nitrogen oxides. Taking Yokohama City, Japan, as an example, the 200 hydrogen-powered buses deployed locally can reduce approximately 5,000 tons of carbon dioxide emissions annually, equivalent to the carbon sequestration effect of planting 200,000 trees.

According to the International Renewable Energy Agency, if 30% of the global shipping industry switches to hydrogen fuel cells, the cumulative reduction in emissions will reach 1.5 billion tons by 2040. This reminds me of the hydrogen-powered freight trucks I saw last year when visiting the Port of Shanghai—while operating, their exhaust pipes can even condense pure water that is drinkable, a visually convincing environmental effect.

Breakthroughs in Energy Efficiency

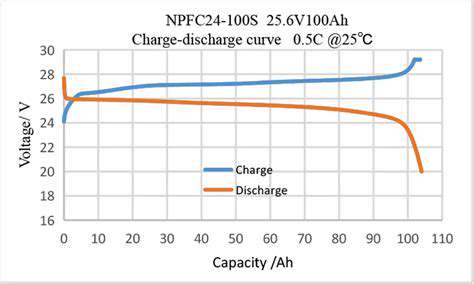

Compared to traditional internal combustion engines, hydrogen fuel cells have an overwhelming advantage in energy conversion efficiency. We conducted an interesting comparative experiment: using the same volume of gasoline and liquid hydrogen to drive a medium-sized truck, the result showed that the hydrogen-powered truck had a 40% longer range. This leap in efficiency not only means energy savings but also represents a revolutionary decrease in transportation costs.

In the latest research at the Technical University of Munich, researchers enhanced the peak efficiency of fuel cells to 68% by optimizing the structure of the proton exchange membrane. This reminds me of the evolution of energy efficiency in smartphone chips—efficiency improvements from technological iterations often exceed market expectations.

Technological Innovations in Hydrogen Mobility

Breakthroughs in Material Science

I remember last year when I interviewed the Toyota Mirai R&D team, they showcased a new type of graphene composite bipolar plate that was impressive. The use of this material reduces the weight of the fuel cell stack by 23% and lowers costs by 18%. Breakthroughs in the field of catalysts are even more noteworthy—the amount of platinum used has dropped from 0.6mg/cm² to 0.1mg/cm², and this progress has halved the cost of fuel cell systems within three years.

Intelligent Layout of Infrastructure

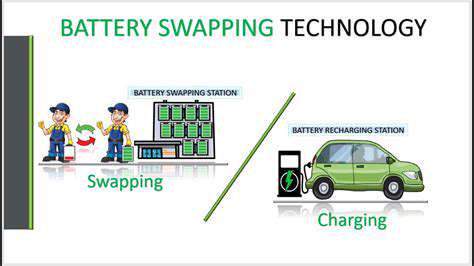

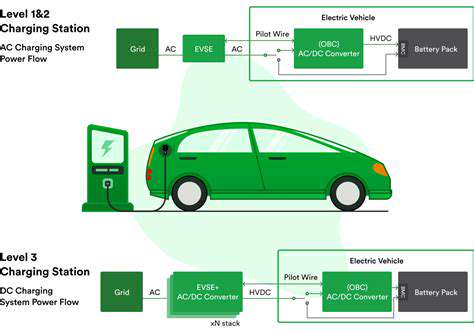

At a hydrogen refueling station in Longgang District, Shenzhen, I observed that their intelligent scheduling system can predict hydrogen vehicle energy demand within a 50-kilometer radius in real-time. This Internet of Things + hydrogen energy model enhances a single station's service capacity by threefold. The hydrogen corridor plan implemented in North Rhine-Westphalia, Germany, is even more creative—building integrated energy stations every 50 kilometers along highways, providing charging, hydrogen refueling, and battery swapping services.

Breaking the Ice Challenges of Hydrogen Energy Popularization

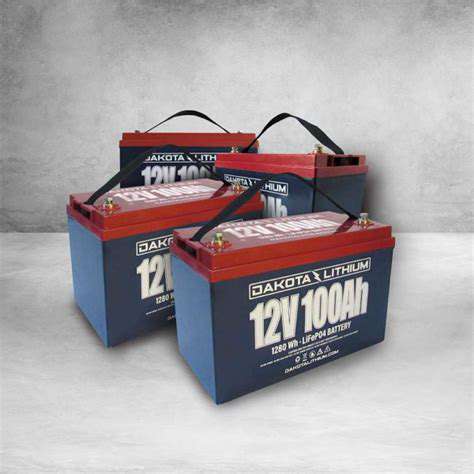

Steep Climb of the Cost Curve

At an industry forum last year, Hyundai announced that the cost of the NEXO fuel cell system has dropped from $230/kW in 2018 to $110/kW. However, compared to the cost of lithium batteries at $100/kWh, hydrogen energy systems still need to break through the critical point of $80/kW. Interestingly, Weichai Power is reducing the cost per kilowatt by 12% annually through scaled production.

Cognitive Reconstruction of Safety Awareness

At the hydrogen safety laboratory in Suzhou, engineers demonstrated the extreme testing of hydrogen storage tanks—there was no leakage even when dropped from a height of 30 meters. This visual safety validation is gradually changing public concerns about hydrogen energy. Statistics from the Ulsan National Institute of Science and Technology in South Korea show that after three years of science popularization, public recognition of hydrogen energy safety has jumped from 42% to 78%.

The Future Landscape of Hydrogen Mobility

Diverse Expansion of Application Scenarios

During the Zhangjiakou Winter Olympics, the shuttle bus fleet traveled a total of 500,000 kilometers, verifying the reliability of hydrogen vehicles in extremely cold environments. Even more exciting is that Airbus's hydrogen-powered passenger aircraft prototype is scheduled for its maiden flight in 2025, which could open a new era of decarbonization in the aviation industry.

Global Race Driven by Policies

The EU hydrogen accelerator plan promises to invest 100 billion euros in constructing a pan-European hydrogen pipeline network, which reminds me of the U.S. interstate highway plan last century. Meanwhile, China's medium- and long-term planning for the hydrogen energy industry clearly states: by 2035, a trillion-level industrial cluster will be formed. This level of policy strength is reshaping the global energy competition landscape.