Understanding EV Repair Costs and Timeframes

Component-Specific Repair Costs: Beyond the Battery

Component-Specific Repair Costs: Braking System

Brake system repairs vary widely depending on the component involved. Routine maintenance, such as pad replacement, is usually affordable, often costing a few hundred dollars based on the vehicle's make and model. However, problems with calipers, rotors, or brake lines can quickly become expensive. For example, replacing a faulty caliper might cost hundreds, while severe rotor damage could double that expense. Specialized diagnostics and labor time also contribute to the final price.

Major brake system overhauls, like replacing the entire system, can be extremely costly, sometimes exceeding several thousand dollars. The extent of damage, repair complexity, and parts availability all influence the final cost. Older vehicles may have more intricate or worn components, leading to higher repair expenses.

Component-Specific Repair Costs: Electrical System

Electrical system repairs range from simple fixes to complex overhauls. Minor issues like blown fuses or faulty bulbs are inexpensive, usually under $50. However, more serious problems, such as a malfunctioning alternator or damaged wiring harness, can be far more costly. The need for specialized tools and skilled labor often drives up the price significantly.

Issues with the vehicle's computer system or control modules are among the most expensive. Diagnosing these problems requires advanced equipment and expertise, leading to higher labor costs. Additionally, the parts themselves can be pricey, further increasing the total repair bill. Costs vary widely depending on the specific issue and vehicle model.

Component-Specific Repair Costs: Engine System

Engine repairs are typically some of the most expensive a vehicle owner can face. Problems with internal components like pistons, valves, or camshafts often require costly replacements. These repairs demand specialized tools and highly trained technicians, which significantly raises labor costs. Parts for high-performance or rare vehicles can be especially expensive, with repairs sometimes exceeding several thousand dollars.

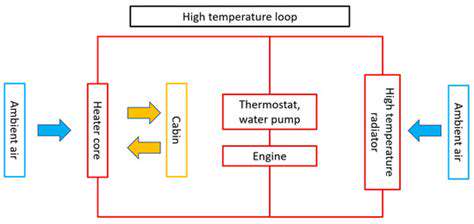

Cooling system issues, such as a failing radiator or water pump, can also be costly. The final price depends on the damage extent and repair complexity. Parts availability may also affect both repair time and cost. Engine repairs require substantial attention and can quickly become a major financial burden.

Repair Timeframes: Factors and Expectations

Repair Time Estimation: Initial Considerations

Accurate repair timeframes are vital for project management and customer satisfaction. A thorough initial assessment of the issue, available resources, and potential complications is crucial to avoid delays. Clearly defining the problem, including specific components or systems involved, is the first step toward an accurate diagnosis.

Impact of Component Availability

Parts availability is a major factor in repair timelines. Delays can occur if components are out of stock or require special ordering. Rare or obsolete parts may prolong the repair process considerably, especially if supply chain disruptions or manufacturing delays are involved.

Complexity of the Repair

The repair's complexity directly affects the time required. Simple fixes may take a few hours, while complex repairs can span days or even weeks. Factors like required expertise, number of steps, and specialized tools all contribute to the timeline. For example, a software bug might be resolved quickly, whereas repairing a damaged circuit board could take much longer.

Staff Expertise and Availability

Skilled technicians are essential for timely repairs, but their availability can be limited. Efficient scheduling and adequate staffing are key to meeting deadlines. Continuous training ensures technicians stay updated on the latest repair techniques, improving overall efficiency.

External Factors Influencing Repair Time

Unforeseen issues, such as equipment malfunctions or unexpected complications, can extend repair times. Regulatory requirements or safety protocols may also introduce delays, even though they're necessary for compliance.

Contingency Planning and Communication

Having backup plans for unexpected delays helps minimize disruptions. Keeping clients informed about potential setbacks fosters transparency and trust. Regular updates on repair progress ensure expectations are managed effectively.

Read more about Understanding EV Repair Costs and Timeframes

Hot Recommendations

- Utility Scale Battery Storage: Successful Project Case Studies

- The Role of Energy Storage in Grid Peak Shaving

- The Role of Startups in Renewable Energy

- The Role of Blockchain in Decentralization of Energy Generation

- The Future of Wind Energy Advancements in Design

- Synchronous Condensers and Grid Inertia in a Renewable Energy Grid

- Corporate Renewable Procurement for Government Agencies

- The Global Push for Long Duration Energy Storage

- Renewable Energy and Job Creation: A Growing Sector

- Energy Storage in Commercial and Industrial Applications