Wind Turbine Blade Recycling: Innovative Solutions for Composite Materials

Challenges in Current Blade Recycling Practices

Material Degradation and Contamination

One significant challenge in blade recycling is the degradation of the blade's material properties during the recycling process. The high temperatures and pressures often involved in melting and reforming the metal can compromise the original strength and durability of the blade material. This degradation can make the recycled blade less suitable for its original purpose, potentially impacting its performance and lifespan. Contamination from various sources, such as impurities from the manufacturing process or other materials encountered during use, can also affect the quality of the recycled blade.

Furthermore, the presence of contaminants can lead to inconsistencies in the recycled material's composition and properties. This can make it difficult to maintain a consistent quality standard across different batches of recycled blades. Addressing these issues requires careful process optimization and the implementation of effective purification techniques.

Economic Viability of Recycling

The economic viability of blade recycling is another critical hurdle. The costs associated with the collection, transportation, and processing of blades can be substantial, potentially outweighing the economic benefits derived from the recycled materials. The profitability of recycling operations depends heavily on factors like the scale of blade production, the availability of suitable recycling facilities, and the market demand for the recycled material.

Moreover, the development and implementation of cost-effective recycling technologies are necessary to achieve a financially sustainable recycling process. Innovative approaches to minimize waste generation and improve the efficiency of recycling processes are crucial to make this endeavor economically viable.

Complexity of Blade Design and Composition

The intricate design of modern blades, incorporating various alloys and composite materials, presents a significant challenge for recycling. Different materials within a single blade can react differently to the recycling process, leading to inconsistent outcomes. This heterogeneity can make it difficult to separate and process the different components effectively, resulting in a lower quality recycled material. The complex composition further complicates the process of sorting and separating the materials, requiring specialized equipment and skilled personnel.

Separation and Purification Techniques

Developing effective separation and purification techniques for different blade materials is essential for efficient recycling. The presence of various metallic alloys and composite materials requires sophisticated methods to isolate and purify the components for reuse. For example, advanced magnetic separation techniques may be needed for certain types of blades with embedded metallic components. Advanced sorting techniques, including optical recognition or automated sorting based on material properties, can greatly enhance the efficiency and accuracy of the separation process.

Environmental Impact of Recycling Processes

The environmental impact of blade recycling processes must be carefully considered. The energy consumption during melting, refining, and shaping of the recycled materials can contribute to greenhouse gas emissions. Therefore, efforts must be made to minimize the environmental footprint of the recycling process. The use of renewable energy sources and the implementation of energy-efficient technologies in the recycling facilities are crucial steps to reduce the environmental burden.

Regulatory and Policy Framework

The lack of a well-defined regulatory and policy framework surrounding blade recycling can hinder its widespread adoption. Clear guidelines and standards for blade recycling are necessary to ensure the quality and safety of the recycled materials. Standardized protocols and regulations for recycling processes will promote consistency and accountability, encouraging responsible waste management practices. This includes establishing appropriate regulations for the disposal of hazardous materials and the proper handling of recycled materials.

Economic and Environmental Benefits of Sustainable Recycling

Economic Benefits of Sustainable Recycling Programs

Sustainable recycling programs offer significant economic advantages, extending far beyond the simple act of diverting waste from landfills. Reduced waste disposal costs are a major factor. Landfills require substantial infrastructure investments, including land acquisition, waste management systems, and ongoing maintenance. Recycling programs, by diverting materials, directly reduce these costs, freeing up capital for other essential projects. Furthermore, the recovery of valuable materials from recycled products can generate substantial revenue streams, creating new income opportunities within the community.

The creation of new jobs in the recycling industry is another key economic benefit. Recycling facilities, processing plants, and related support services require skilled labor, fostering economic growth and providing employment opportunities for local communities. This ripple effect extends to the wider economy, as the demand for recycled materials stimulates related industries, such as manufacturing and construction.

Environmental Benefits of Sustainable Recycling

Sustainable recycling initiatives play a crucial role in mitigating the environmental impact of waste generation. Recycling reduces the demand for virgin raw materials, preserving natural resources like timber, minerals, and fossil fuels. The extraction and processing of these resources often have significant environmental consequences, including habitat destruction, pollution, and greenhouse gas emissions. Recycling lessens the strain on these vital resources, contributing to a more sustainable future.

Recycling significantly reduces landfill waste, minimizing the environmental problems associated with landfills. Landfills release methane, a potent greenhouse gas, contributing to climate change. By diverting waste from landfills, recycling programs effectively reduce methane emissions, helping to mitigate the impact of climate change on our planet. Recycling also contributes to the preservation of valuable natural habitats by reducing the need to clear land for new landfills.

Reduced Carbon Footprint Through Recycling

Recycling processes often have a significantly lower carbon footprint compared to extracting and processing virgin materials. The energy required to manufacture new products from raw materials is often substantial. Recycling, by contrast, requires less energy, leading to a reduction in greenhouse gas emissions and a decrease in the overall carbon footprint of the production cycle. This is particularly important in industries where manufacturing processes produce high levels of carbon emissions, such as the production of metals and plastics.

Resource Conservation and Material Recovery

Recycling programs are essential for conserving natural resources. The extraction of raw materials from the earth can have devastating consequences for ecosystems, including habitat destruction, water pollution, and soil degradation. Recycling programs help to reduce the pressure on these resources, allowing them to regenerate naturally and ensuring their availability for future generations. By recovering valuable materials from waste, recycling programs minimize the need for new resource extraction, promoting a more sustainable use of our planet's resources.

Economic Viability of Recycling Programs

The economic viability of recycling programs depends on factors such as the availability of suitable recycling infrastructure, market demand for recycled materials, and the efficiency of the recycling process itself. Effective program design, including community engagement, sorting techniques, and transportation logistics, is crucial for optimizing the economic viability of recycling initiatives. Government policies, including subsidies for recycling facilities and incentives for businesses to participate in recycling programs, play a vital role in supporting the economic viability of these programs.

Community Engagement and Public Awareness

Successful recycling programs rely heavily on community engagement and public awareness. Educating residents about the benefits of recycling and the importance of proper waste disposal is crucial for program success. Community awareness campaigns, educational initiatives, and partnerships with local organizations can significantly increase recycling participation rates and foster a culture of sustainability. Dedicated community centers, educational programs, and outreach initiatives can help promote awareness and responsibility in waste management.

The Role of Technology in Enhancing Recycling Efficiency

Modern technologies are continually improving the efficiency and effectiveness of recycling programs. Advanced sorting technologies, such as automated optical sorting systems and advanced material separation techniques, allow for more accurate and comprehensive material recovery. These innovations increase the quality and quantity of recycled materials, enhancing the economic and environmental benefits of recycling programs. Furthermore, technologies like sensor systems and data analytics can monitor and optimize recycling processes, leading to greater efficiency and reduced waste.

Read more about Wind Turbine Blade Recycling: Innovative Solutions for Composite Materials

Hot Recommendations

- Offshore Wind for Industrial Power

- Agrivoltaics: Dual Land Use with Solar Energy Advancements: Sustainable Farming

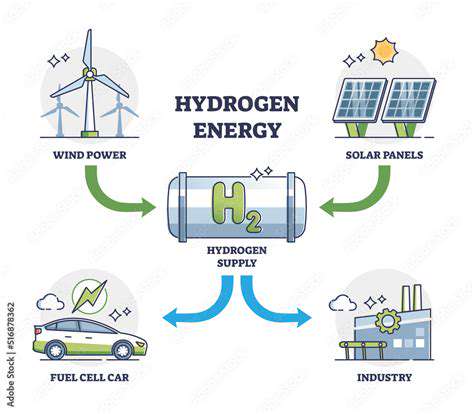

- Hydrogen as an Energy Storage Medium: Production, Conversion, and Usage

- Utility Scale Battery Storage: Successful Project Case Studies

- The Role of Energy Storage in Grid Peak Shaving

- The Role of Startups in Renewable Energy

- The Role of Blockchain in Decentralization of Energy Generation

- The Future of Wind Energy Advancements in Design

- Synchronous Condensers and Grid Inertia in a Renewable Energy Grid

- Corporate Renewable Procurement for Government Agencies