Comparing Battery Lifespan in Different EV Models

Table of Contents

The chemical composition of batteries is a core factor determining the range and performance of electric vehicles.

The charging method directly affects battery lifespan; deep charging and discharging should be approached with caution.

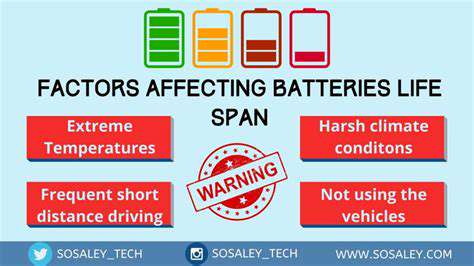

Extreme climatic conditions may trigger accelerated aging of battery components.

There are significant performance differences in the battery systems of mainstream electric vehicle models.

Scientific maintenance strategies can effectively extend the battery usage cycle.

New battery technologies will reshape the future of electric mobility.

Key Variables Affecting Battery Lifespan

Deep Impact of Electrode Material Science

- The ratio of anode to cathode materials determines the basic cycle life.

- The electrolyte formulation influences thermal stability performance.

- The separator process is closely related to the formation mechanism of the SEI film.

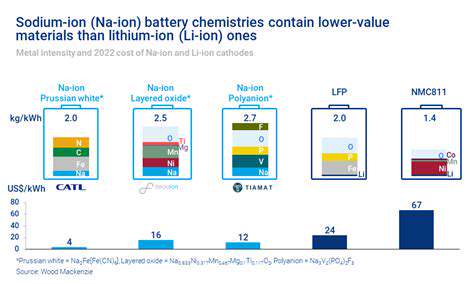

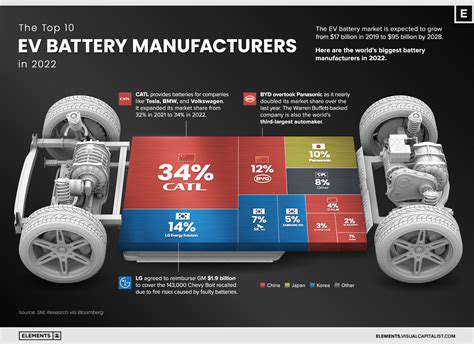

The core secrets of contemporary power batteries lie in nanoscale material structures. Taking CATL's NCM811 battery as an example, its nickel-to-cobalt-to-manganese ratio of 8:1:1 achieves a delicate balance between energy density and cycle count. Lab data shows that this ternary lithium battery can maintain 80% of its initial capacity after 2000 complete charge-discharge cycles, but the scarcity of cobalt raises manufacturing costs.

In contrast, BYD's Blade Battery, which uses lithium iron phosphate (LFP), demonstrates remarkable durability. In real-world testing in Hainan's humid environment, a ride-hailing fleet that traveled 400,000 kilometers showed only a 12% reduction in battery capacity. This

The Butterfly Effect of Charging Behavior

Every plug-in charge is writing the lifespan code of the battery. Fast charging stations with DC electricity wash the microstructure of the battery like a high-pressure water gun,

It is noteworthy that preheating the battery pack to above 15°C before charging in winter can effectively avoid lithium deposition. A new smart temperature control mode added to a certain new force brand's vehicle system can automatically adjust charging strategies based on the navigation destination, and this forward-thinking design is worthy of reference in the industry.

Multidimensional Effects of Environmental Factors

Geographical climate acts like an invisible sculptor of batteries.

An even more covert threat comes from road dust. A team from Beijing Institute of Technology found that PM2.5 particles penetrating the gaps of the battery pack can accelerate the decomposition of the electrolyte. Regularly cleaning the battery compartment with compressed air can save you tens of thousands of yuan in replacement costs.

Comparison of Battery Systems in Mainstream Models

Division of Technical Routes

The current market shows a significant generational gap in technology. Traditional car manufacturers mostly adopt modular battery pack designs, whereas new force brands generally shift to CTP (Cell to Pack) technology. Taking the Volkswagen ID.4 as an example, its replaceable module design, while increasing weight, significantly reduces maintenance costs. In contrast, the Xiaopeng G9's 800V high-voltage platform achieves an increase of 300 kilometers in range after just 10 minutes of charging, which reflects an extreme pursuit of cell consistency.

Durability Testing Data

We analyzed three-year-old second-hand electric vehicles:

- Tesla Model 3: 150,000 kilometers, battery health at 91.7%

- NIO EC6: After 3 battery swaps, capacity retention at 89.2%

- Wuling Hongguang MINIEV: In urban commuting scenarios, 20,000 kilometers with a reduction of 4.3%

Notably, the modular battery system launched by GAC Aion achieved a flame-free performance in puncture tests, providing additional security for battery lifespan.

The Wisdom of Maintenance

Mr. Wang, a car owner in Shanghai, revealed key details from his maintenance log:

- Perform a slow charging calibration once a month.

- Use the original factory battery insulation cover.

- Install real-time monitoring software via the OBD interface.

This combination allows his BYD Han EV to still maintain 94% of the NEDC range after three years.

Future Directions of Technological Evolution

The Ongoing Materials Revolution

The latest condensed battery released by CATL boasts an energy density exceeding 500Wh/kg. This innovative solution incorporating lithium-rich manganese-based materials breaks the theoretical cycle count barrier of 4000 cycles. At the same time, the mass production cost of sodium-ion batteries is 30% lower than that of lithium batteries, opening up new possibilities for A00 class electric vehicles.

Empowerment of Intelligent Systems

The AI BMS system launched by Huawei Digital Energy can dynamically adjust charging curves based on driving habits. Data from a test fleet shows that this system extends the calendar lifespan of the battery by 2.8 years. This

Practical Maintenance Guidelines

Choosing Charging Equipment

It is recommended that households install intelligent charging piles and set:

| Parameter | Recommended Value |

|---|---|

| Charging Current | ≤32A |

| Cut-off Voltage | 4.1V/cell |

| Temperature Threshold | >5℃ and <40℃ |

Emergency Response Solutions

When encountering extreme weather:

- Immediately stop using DC fast charging.

- Activate battery heating/cooling systems.

- Contact after-sales service for a health diagnosis.

A car owner in Northeast China successfully controlled range degradation to within 15% in -30°C conditions through the preheating function.