New Materials for Wind Energy Advancements Turbines: Lighter and Stronger

Introduction to the Material Revolution in Wind Energy

Understanding the Core Principles

The material revolution, a multifaceted phenomenon encompassing advancements in materials science, engineering, and manufacturing, is fundamentally reshaping industries and daily life. At its core, this revolution is driven by a relentless pursuit of materials with superior properties, such as enhanced strength, durability, conductivity, and biocompatibility. The interplay between scientific discovery, technological innovation, and practical application is central to understanding this transformation.

This evolution isn't merely about replacing existing materials; it's about creating entirely new functionalities and applications. The development of novel composites, nanomaterials, and advanced polymers is driving progress across various sectors, from aerospace and automotive to healthcare and consumer electronics.

Impact on Various Industries

The material revolution is profoundly impacting a broad spectrum of industries. In aerospace, lighter and stronger materials are enabling the development of more efficient aircraft, reducing fuel consumption and emissions. This translates to significant advancements in environmental sustainability and cost-effectiveness. The automotive industry is also witnessing a transformation, with the adoption of high-strength, lightweight materials leading to improved fuel efficiency and vehicle performance.

Furthermore, the medical field is benefiting from biocompatible materials, fostering breakthroughs in tissue engineering, implants, and drug delivery systems. These advancements are improving patient outcomes and quality of life.

Technological Advancements Driving the Revolution

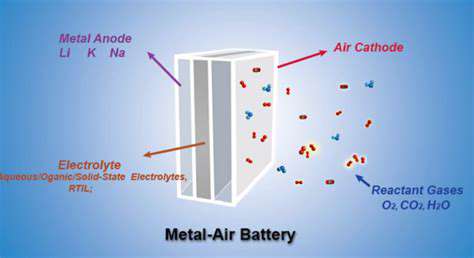

Several key technological advancements are propelling the material revolution forward. Nanotechnology, for instance, allows for the creation of materials with unprecedented properties at the nanoscale, opening up possibilities for applications ranging from electronics to energy storage. The precise manipulation of atoms and molecules at this level leads to materials with unique functionalities.

Additive manufacturing (3D printing) is another crucial technology, enabling the creation of complex shapes and structures from a wide array of materials. This approach allows for customized designs and reduced material waste, fostering innovation and efficiency.

Challenges and Future Directions

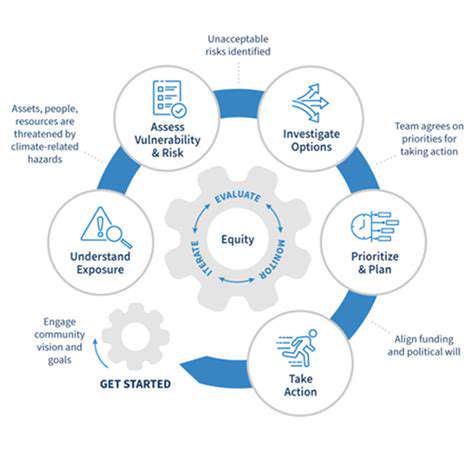

While the material revolution presents immense opportunities, it also comes with challenges. Sustainable sourcing of raw materials and responsible disposal of materials are crucial considerations in ensuring long-term environmental impact is minimized. Addressing these concerns will be paramount for the widespread adoption and sustainability of the revolution.

Future directions in material science research are likely to focus on developing even more advanced materials with tailored functionalities. This includes exploring new avenues for integrating advanced materials into existing technologies and creating entirely new applications. The potential for transformative innovations in various fields is immense.

Advanced Alloys for Enhanced Strength and Durability

Advanced Alloy Composition

The composition of advanced alloys is meticulously crafted to optimize desired properties. This involves carefully selecting and combining various metallic elements, often including rare earth metals or transition metals. The precise ratios of these elements significantly impact the final alloy's strength, ductility, and resistance to corrosion. Understanding the interplay of these elements is crucial for achieving the desired performance characteristics.

Microstructure Manipulation

Advanced techniques, such as specialized heat treatments and controlled cooling processes, are employed to manipulate the microstructure of the alloy. These methods influence the grain size, distribution, and shape of the constituent phases, ultimately affecting the material's mechanical properties. Careful control over these processes is essential for developing alloys with superior mechanical properties.

Enhanced Strength and Durability

Advanced alloys are designed to exhibit exceptional strength and durability. This is achieved through the creation of a microstructure that effectively resists deformation under stress and prevents crack propagation. The result is a material capable of withstanding higher loads and maintaining its integrity under extreme conditions. This enhanced durability is a key advantage in various applications.

Improved Corrosion Resistance

Many advanced alloys showcase exceptional corrosion resistance, stemming from their unique chemical composition and microstructure. This resistance is vital in applications exposed to harsh environments or corrosive substances. The ability to withstand these conditions without degradation significantly extends the lifespan and reliability of components made from these materials.

Elevated Temperature Performance

Advanced alloys are often engineered for superior performance at elevated temperatures. This is critical in applications like jet engines and high-temperature industrial processes. The ability to maintain strength and stability at elevated temperatures is essential for high-performance applications.

Manufacturing and Processing Challenges

Producing advanced alloys often presents unique manufacturing and processing challenges. These challenges stem from the complex compositions and demanding processing requirements needed to achieve the desired microstructure. Overcoming these challenges is crucial for cost-effective and reliable production of these materials.

Applications in Diverse Industries

Advanced alloys find applications across a wide range of industries, including aerospace, automotive, and energy. These alloys enable the development of lighter, stronger, and more durable components. The versatility of these alloys is a key factor in their widespread adoption. Their use in critical applications necessitates meticulous quality control and testing throughout the manufacturing process.

Smart Materials for Dynamic Performance Optimization

Smart Materials for Dynamic Performance Enhancement

Smart materials, characterized by their ability to respond to external stimuli, are revolutionizing various industries, particularly in the realm of dynamic performance enhancement. These materials possess unique properties that enable them to adapt and change their physical characteristics in response to environmental factors like temperature, pressure, or even electrical fields. This remarkable adaptability opens up exciting possibilities for creating innovative products and systems that can outperform traditional materials.

Their responsiveness to external stimuli is a key advantage, allowing for precise control and optimization of performance in dynamic applications. This responsiveness is often achieved through intricate internal mechanisms that subtly alter the material's structure and properties, leading to enhanced functionality and efficiency.

Applications in Aerospace Engineering

In the demanding environment of aerospace engineering, smart materials are proving invaluable. Their ability to adjust to fluctuating temperatures and pressures during flight can significantly improve aircraft performance and safety. This is particularly important in high-altitude conditions and during extreme maneuvers.

For instance, smart composites can actively adapt to changing aerodynamic forces, optimizing lift and reducing drag. This, in turn, leads to increased fuel efficiency and reduced environmental impact.

The use of smart materials in aerospace is still in its nascent stages, but the potential benefits are enormous. Continued research and development are expected to lead to further advancements in this exciting field.

Impact on Construction and Infrastructure

Beyond aerospace, smart materials are finding applications in construction and infrastructure projects. Their ability to self-repair and adapt to environmental stresses can significantly improve the longevity and resilience of structures. Imagine buildings that can dynamically adjust to changing weather conditions, or bridges that can automatically repair cracks before they become major structural issues.

These materials could usher in a new era of sustainable infrastructure, reducing maintenance costs and minimizing environmental damage. The implementation of such materials is a promising step towards more resilient and eco-friendly construction practices.

Advancements in Robotics and Automation

Smart materials are also transforming the field of robotics and automation. Their ability to sense and respond to external forces makes them ideal components for creating robots that can adapt to complex and unpredictable environments. Think of robots that can adjust their grip strength in response to the weight or fragility of an object they are handling.

This enhanced responsiveness leads to improved dexterity and precision in robotic tasks, enabling them to perform intricate operations with greater accuracy and efficiency. This translates to significant advancements in manufacturing, healthcare, and other sectors.

Future Trends and Challenges

The future of smart materials is bright, with ongoing research and development leading to even more sophisticated and versatile materials. Scientists are exploring new ways to integrate smart materials into existing systems, aiming to create more integrated and adaptable solutions.

However, challenges remain, including the high cost of production, the need for robust testing procedures, and the development of suitable manufacturing methods. Overcoming these obstacles will be critical to unlocking the full potential of smart materials in various industries.

Despite these challenges, the potential benefits of smart materials are undeniable, promising to revolutionize industries and improve our lives in myriad ways. Further research and development in this area will undoubtedly yield groundbreaking advancements in the coming years.

Read more about New Materials for Wind Energy Advancements Turbines: Lighter and Stronger

Hot Recommendations

- Offshore Wind for Industrial Power

- Agrivoltaics: Dual Land Use with Solar Energy Advancements: Sustainable Farming

- Hydrogen as an Energy Storage Medium: Production, Conversion, and Usage

- Utility Scale Battery Storage: Successful Project Case Studies

- The Role of Energy Storage in Grid Peak Shaving

- The Role of Startups in Renewable Energy

- The Role of Blockchain in Decentralization of Energy Generation

- The Future of Wind Energy Advancements in Design

- Synchronous Condensers and Grid Inertia in a Renewable Energy Grid

- Corporate Renewable Procurement for Government Agencies