The Future of Self Healing Materials in EV Design

Government Incentives and Policies

From Oslo to Ottawa, policymakers recognize EVs' role in meeting climate targets. Norway's comprehensive approach - combining tax exemptions, toll waivers, and charging infrastructure - demonstrates how coordinated policies can achieve 80% EV market penetration. Such initiatives prove that well-designed government intervention can accelerate sustainable technology adoption.

Infrastructure Development for Charging

The charging network expansion resembles the early days of gas stations, but with 21st century smarts. Companies like Electrify America are deploying ultra-fast chargers along highways while municipalities install curbside options in urban areas. This infrastructure rollout must keep pace with EV sales growth to prevent bottlenecks in adoption.

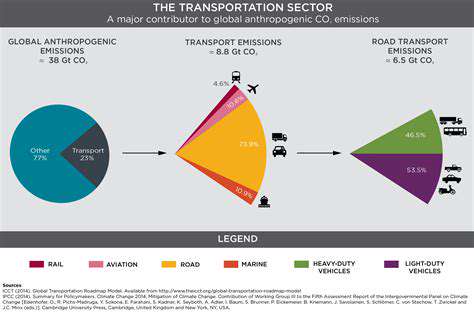

Environmental Benefits of Electric Vehicles

While skeptics question the environmental impact of battery production, lifecycle analyses consistently show EVs' advantage. Even when charged using today's electricity mix, EVs produce fewer emissions than comparable gas vehicles. As grids transition to renewables, this advantage will only grow more pronounced.

Consumer Acceptance and Market Growth

Early adopters paved the way, but mainstream buyers now drive EV market expansion. Automakers report that test drives convert more skeptics than any marketing campaign. This hands-on experience helps consumers realize that modern EVs meet - and often exceed - their daily transportation needs.

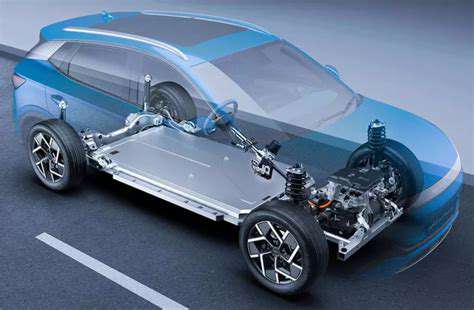

The Future of the Automotive Industry

Traditional automakers face their Kodak moment as Tesla and Chinese manufacturers demonstrate the advantages of EV-native platforms. Companies that successfully navigate this transition will thrive, while those clinging to combustion technology risk obsolescence. The coming decade will determine which brands become the automotive leaders of the mid-21st century.

Self-Healing Polymers: A Game Changer for EV Body Panels and Internal Components

Self-Healing Polymers: A Game Changer in Materials Science

Self-healing polymers represent materials science's most exciting frontier since carbon fiber composites. These innovative materials don't just withstand damage - they actively repair themselves through remarkable chemical processes. This breakthrough could dramatically reduce maintenance costs while extending product lifespans across multiple industries.

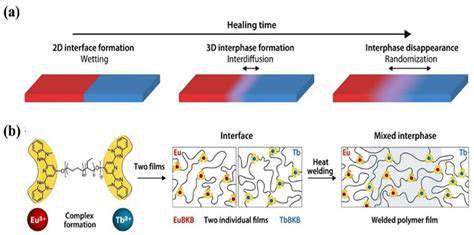

Mechanism of Self-Healing

The science behind these materials reads like science fiction. Microscopic capsules containing specialized healing agents remain dormant until damage occurs. When cracks form, these capsules rupture, releasing agents that polymerize to fill gaps. Researchers continue refining these systems to handle larger-scale damage more efficiently.

Applications Across Diverse Industries

EV manufacturers particularly value these materials for exterior panels that can repair minor scratches automatically. Imagine parking lot dings disappearing by morning without costly body shop visits. Aerospace engineers see potential for wing components that seal micro-fractures during flight, while civil engineers envision bridges that self-repair stress cracks.

Challenges and Future Research Directions

Current limitations include healing speed and the size of repairable damage. Materials that can heal centimeter-scale cracks in minutes rather than hours would revolutionize industrial applications. Researchers are exploring biological inspiration, studying how human skin heals, to develop next-generation solutions.

Economic and Environmental Impact

The financial implications are staggering. A single self-healing car panel could save owners thousands in repair costs over a vehicle's lifetime. From an ecological perspective, reducing replacement parts could significantly cut manufacturing emissions and landfill waste.

Beyond Polymers: Exploring Self-Healing Composites and Metals

Self-Healing Polymers: A Foundation for the Future

These materials have proven their worth in low-stress applications, but researchers now push boundaries. Recent breakthroughs involve embedding shape-memory alloys within polymer matrices, creating composites that restore their original form after deformation. Such innovations could transform everything from athletic equipment to medical implants.

Metals: The Next Frontier of Self-Healing Materials

The holy grail remains self-healing structural metals. Scientists at several universities have demonstrated limited success with copper and aluminum alloys that partially repair cracks at high temperatures. While practical applications remain years away, these early successes suggest a future where metal fatigue becomes a solvable problem rather than an inevitable failure mode.

Composite Materials: Synergistic Self-Healing Properties

By layering different self-healing materials, engineers create composites where each component contributes unique repair capabilities. A carbon fiber panel might combine polymer-based surface healing with metal-assisted structural repair, offering comprehensive damage resistance.

Applications Across Industries: From Aerospace to Infrastructure

The potential extends far beyond transportation. Imagine wind turbine blades that repair erosion damage or pipeline joints that seal micro-leaks automatically. Such applications could prevent catastrophic failures while dramatically reducing maintenance costs.

Challenges and Future Directions: Overcoming Limitations

Key hurdles include developing healing mechanisms that work at room temperature and standardizing testing protocols. The materials science community currently lacks consensus on how to quantify and compare different systems' healing efficiencies.

The Economic and Environmental Impact: A Sustainable Future

While initial costs remain high, lifecycle analyses suggest these materials could save billions in infrastructure maintenance alone. The environmental case grows stronger as researchers develop bio-based healing agents derived from renewable sources.

Challenges and Future Directions in Self-Healing Material Integration

Integration Strategies and Material Selection

Bridging the gap between laboratory breakthroughs and commercial applications requires solving complex integration challenges. Engineers must consider how self-healing components interact with conventional materials in real-world structures. Thermal expansion mismatches, for instance, can create new failure points even as others are repaired.

Scaling Up Production and Cost-Effectiveness

Current production methods often rely on expensive, small-batch techniques. The key to commercialization lies in adapting existing industrial processes rather than inventing entirely new ones. Several startups are making progress by modifying standard injection molding and composite layup techniques to incorporate healing agents.