The Power of Clean Data in Supply Chain Optimization

Data Accuracy: The Cornerstone of Trust

Maintaining accurate and reliable data throughout the supply chain is paramount to building trust among stakeholders. Inaccurate data about inventory levels, shipping times, or supplier performance can lead to costly delays, missed deadlines, and ultimately, a breakdown in the entire system. Data accuracy ensures that everyone involved in the process has access to the same, up-to-date information, fostering collaboration and efficiency. This fundamental aspect of data integrity is the foundation upon which a resilient and responsive supply chain is constructed.

A focus on data accuracy requires rigorous data validation processes at every stage. This includes verifying the source of data, confirming its completeness, and establishing a clear protocol for correcting errors. By prioritizing data quality, companies can mitigate risks and establish a transparent and accountable system.

Real-Time Visibility: Empowering Informed Decisions

Real-time access to accurate data allows for swift and informed decision-making across the entire supply chain. Knowing precisely where products are, what their status is, and when they're expected to arrive empowers stakeholders to proactively address potential disruptions. This level of visibility enables quick responses to unexpected events, such as weather delays or sudden demand surges.

Leveraging technology to track data in real time is crucial. This includes implementing robust tracking systems, utilizing cloud-based platforms, and establishing clear communication channels between all parties involved in the supply chain. Real-time visibility ensures that all participants are on the same page, promoting collaboration and reducing the risk of costly errors.

Data Integrity and Traceability: Enhancing Transparency

Data integrity plays a vital role in achieving traceability throughout the supply chain. By maintaining accurate records of each step in the process—from raw materials to finished goods—companies can trace products back to their origin, ensuring accountability and enhancing consumer trust. This transparency is particularly valuable in sectors with stringent regulatory requirements and heightened consumer scrutiny.

This detailed record-keeping allows for efficient problem-solving. If a product defect occurs, the ability to track its journey through the supply chain quickly identifies the source of the issue and facilitates prompt corrective action. This not only ensures product safety but also safeguards brand reputation.

Data Security: Protecting Valuable Information

The importance of data security within the supply chain cannot be overstated. Protecting sensitive data, such as customer information, financial records, and intellectual property, is crucial to maintaining a secure and reliable operation. Robust security measures, including encryption, access controls, and regular security audits, are essential to safeguarding this information from unauthorized access and cyber threats.

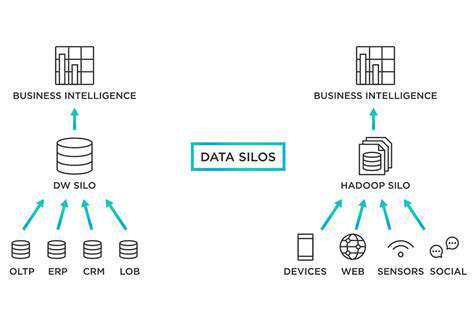

Data Standardization: Streamlining Processes and Collaboration

Standardizing data formats and formats across the entire supply chain facilitates seamless data exchange and collaboration. This approach ensures that different systems and departments can readily interpret and utilize the same information. Standardized data also reduces the risk of errors, as everyone uses the same definitions and formats, leading to improved efficiency and reduced costs.

Implementing a standardized approach requires a thorough analysis of existing processes and systems. This analysis should identify common data elements and establish clear standards for their collection and reporting. By adopting this approach, organizations can create a more efficient and effective supply chain.

Minimally invasive surgical techniques are rapidly transforming the landscape of modern healthcare. These procedures, often performed through small incisions, offer numerous advantages over traditional open surgery. This shift towards less invasive approaches is driven by a desire to reduce patient recovery time and complications, while enhancing the overall surgical experience.

Predictive Analytics: Forecasting Trends and Preventing Issues

Understanding Predictive Analytics

Predictive analytics is a powerful approach to extracting knowledge from data to anticipate future outcomes. It involves using statistical algorithms and machine learning techniques to identify patterns and trends within historical data and project those patterns into the future. This allows organizations to make more informed decisions based on probabilities and potential scenarios, rather than solely relying on intuition or historical averages. Predictive modeling plays a crucial role in various industries, from finance and healthcare to retail and marketing.

By understanding past trends, predictive analytics can forecast future behaviors and outcomes. This process often involves complex data analysis techniques and the use of sophisticated algorithms. The goal is to develop accurate models that can predict future events with a degree of confidence.

Key Applications of Predictive Analytics

Predictive analytics finds widespread application in various sectors. In finance, it can be used to predict potential loan defaults, identify investment opportunities, and manage risk. In healthcare, it can assist in identifying patients at high risk for certain diseases and predict treatment outcomes. Retailers can use predictive analytics to forecast demand, optimize inventory levels, and personalize customer experiences.

The potential benefits are substantial, leading to more efficient resource allocation, reduced risks, and improved decision-making across diverse industries.

Predictive analytics can also help to identify patterns that may not be apparent through traditional methods, leading to more effective strategies and improved outcomes.

Data Preparation and Feature Engineering

Before any predictive model can be built, the data needs to be meticulously prepared. This involves cleaning, transforming, and preparing the data to ensure its quality and suitability for analysis. This crucial step includes handling missing values, correcting inconsistencies, and transforming data into a format suitable for the chosen algorithms. Feature engineering is also critical, where new features are derived from existing data to improve model performance.

Feature engineering is essential for enhancing the model's accuracy and predictive power. This process involves crafting new variables from existing ones, potentially uncovering hidden relationships and patterns within the data.

Model Selection and Evaluation

Choosing the right predictive model is paramount for achieving accurate forecasts. Several different models exist, each with its strengths and weaknesses. The selection process depends on the specific problem being addressed and the characteristics of the data. For example, linear regression might be suitable for simple relationships, while more complex models, like support vector machines or neural networks, might be necessary for more intricate scenarios.

After the model is trained, its performance needs to be rigorously evaluated. Metrics like accuracy, precision, recall, and F1-score are used to assess the model's ability to accurately predict outcomes. Model validation is crucial to ensure that the predictions are reliable and generalizable to new data.

Deploying and Monitoring Predictive Models

Once a predictive model has been developed and validated, it needs to be deployed into a production environment. This usually involves integrating the model into existing business processes and systems. Continuous monitoring of the model's performance is essential to ensure its continued accuracy. As new data becomes available, the model might need to be retrained or adjusted to maintain its predictive power.

Regular retraining and adjustments are necessary to adapt to evolving trends and changing conditions. This ensures the model remains relevant and accurate in the face of dynamic environments. Monitoring also helps to identify potential issues and biases in the model's predictions.

Read more about The Power of Clean Data in Supply Chain Optimization

Hot Recommendations

- Offshore Wind for Industrial Power

- Agrivoltaics: Dual Land Use with Solar Energy Advancements: Sustainable Farming

- Hydrogen as an Energy Storage Medium: Production, Conversion, and Usage

- Utility Scale Battery Storage: Successful Project Case Studies

- The Role of Energy Storage in Grid Peak Shaving

- The Role of Startups in Renewable Energy

- The Role of Blockchain in Decentralization of Energy Generation

- The Future of Wind Energy Advancements in Design

- Synchronous Condensers and Grid Inertia in a Renewable Energy Grid

- Corporate Renewable Procurement for Government Agencies